Features

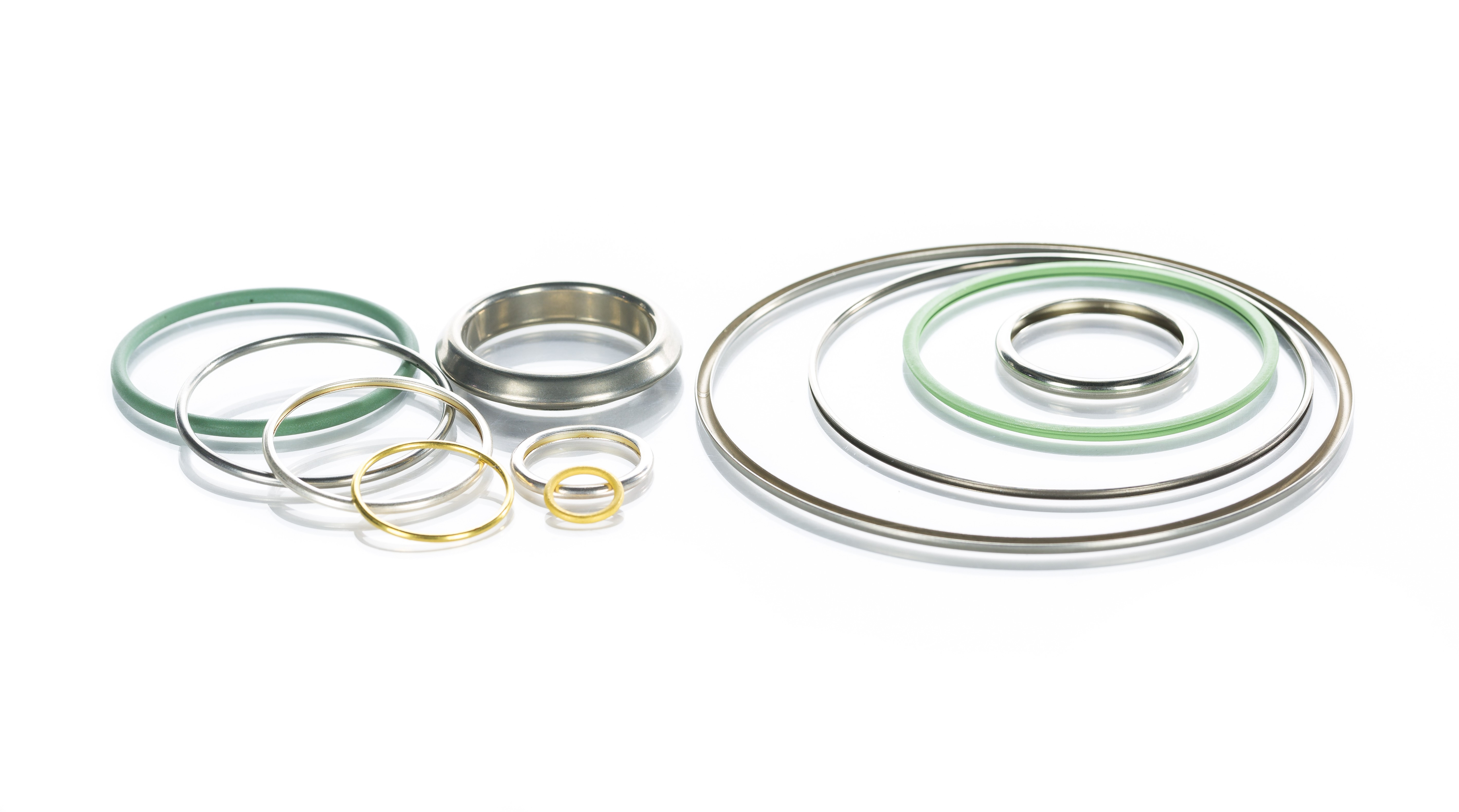

High performance metal seals for the most challenging and critical seal applications

Extreme high & low temperature performance and resistance to highly aggressive chemicals

Wide range of base materials and precious metal plating combinations

Complete seal design service from experienced application engineers using the latest 2D/3D design and simulation software

Excellent

Very Good

Good

Fair

Not Recommended

Our wide range of base metals for seal jackets and springs include various grades of stainless steel including 304, 316, 321 and 347 and high strength nickel alloys including Inconel 718, 625, X750 and Hastelloy and Waspaloy.

Special materials are available for the most demanding of applications, and in order obtain other sealing properties including higher load and spring-back values.

Our metal seals can undergo a variety of heat treatments including Work Hardened, Age Hardened, Annealed and Solution and Precipitation heat treatments. A selection of alloys can also be heat treated to NACE-MR-01-075 specification specifically for applications within the Oil and Gas industry.

Our metal seals are generally supplied with specialised platings and coatings, including; Silver, Gold, Copper, Nickel, Indium, Tin, Lead and PTFE.

Our engineers can recommend the most effective plating material and thickness and supply surface finish guidelines for each individual application.

If you require support with seal selection complete our application form here.