E1244-70 seals in Life Sciences & Medical applications

Packed with multiple benefits, E1244-70 recommended for seals in Life Sciences & Medical applications. Specifically suitable for pharmaceutical manufacturing, biopharmaceutical processing and disposable medical devices, E1244-70 is an internally lubricated compound. With this material, there is no need for an external lubricant.

What is E1244-70?

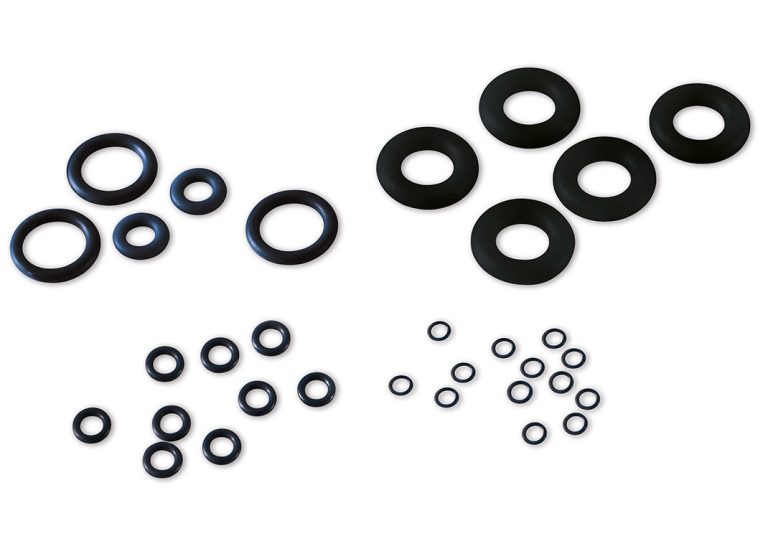

E1244-70 is a 70 durometer internally lubricated, black EPDM (Ethylene Propylene Diene Monomer Rubber) material. Possessing an internal lubricant, which reduces installation force and dynamic friction, E1244-70 is compatible with all water-soluble chemistries. Additionally, it has excellent resistance to repeated conditions such as steam, gamma, ozone and ethylene oxide sterilization.

Adding external lubricants can be problematic due to the risk of leaking into flow paths and migrating into areas where they are not needed. Additionally, even ‘clean’ lubricants like USP silicone, which can trap dirt and dust, can compromise patient health. Removing the need for an external lubricant by using E1244-70 is clean and safe with no risk of leakage.

Benefits, application and use

With a temperature range of -54°C to 121°C (-65 to 250°F), E1244-70 has a low compression set, and is suitable for both dynamic and static seal applications.

Because this material does not need an additional lubricant, it prevents multiple issues associated with non-lubricated seals. For example, mismanagement by not using a lubricant when needed, can lead to friction and heat build-up, resulting in erosion and potential leakage and failure of the application.

The material is compliant with USP Class VI biocompatibility and USP cytotoxicity standards (for life sciences applications). The internal lubricant derives from the fatty acid family, which significantly reduces patient reactions. This means it is safe for medical devices and pharmaceutical applications. In summary, it is suitable for:

- Dynamic applications & difficult installations

- Surgical instruments

- Pharmaceutical manufacturing

- Biopharmaceutical processing

- Disposable medical devices

- Repeated device sterilization

Our Life Sciences & Medical expertise

We have clean room manufacturing facilities which are Class 7 (10,000) manufacturing and Class 5 (100) inspection, cleaning, and packaging.

Our application engineers utilise the latest in 2D/3D CAD and FEA simulation software to design and replicate seal performance. This is before finalising each individual seal design, incorporating significant feature and critical function elements for integration with customer mating parts.

We offer material development and testing, and a component endurance testing service.

Learn more about how we support our customers in the Life Science and Medical Industries HERE