Our seal designs and materials meet the increasing demands of automotive applications and comply with a number of industry standards (PPAP Level 3, IATF 16949) and OEM specifications.

We design and supply seals for applications throughout the whole vehicle; including transmission, braking, cooling, fuel, air and exhaust management, battery, cable and ancillary systems.

Air induction, fuel and exhaust gas management (EGM)

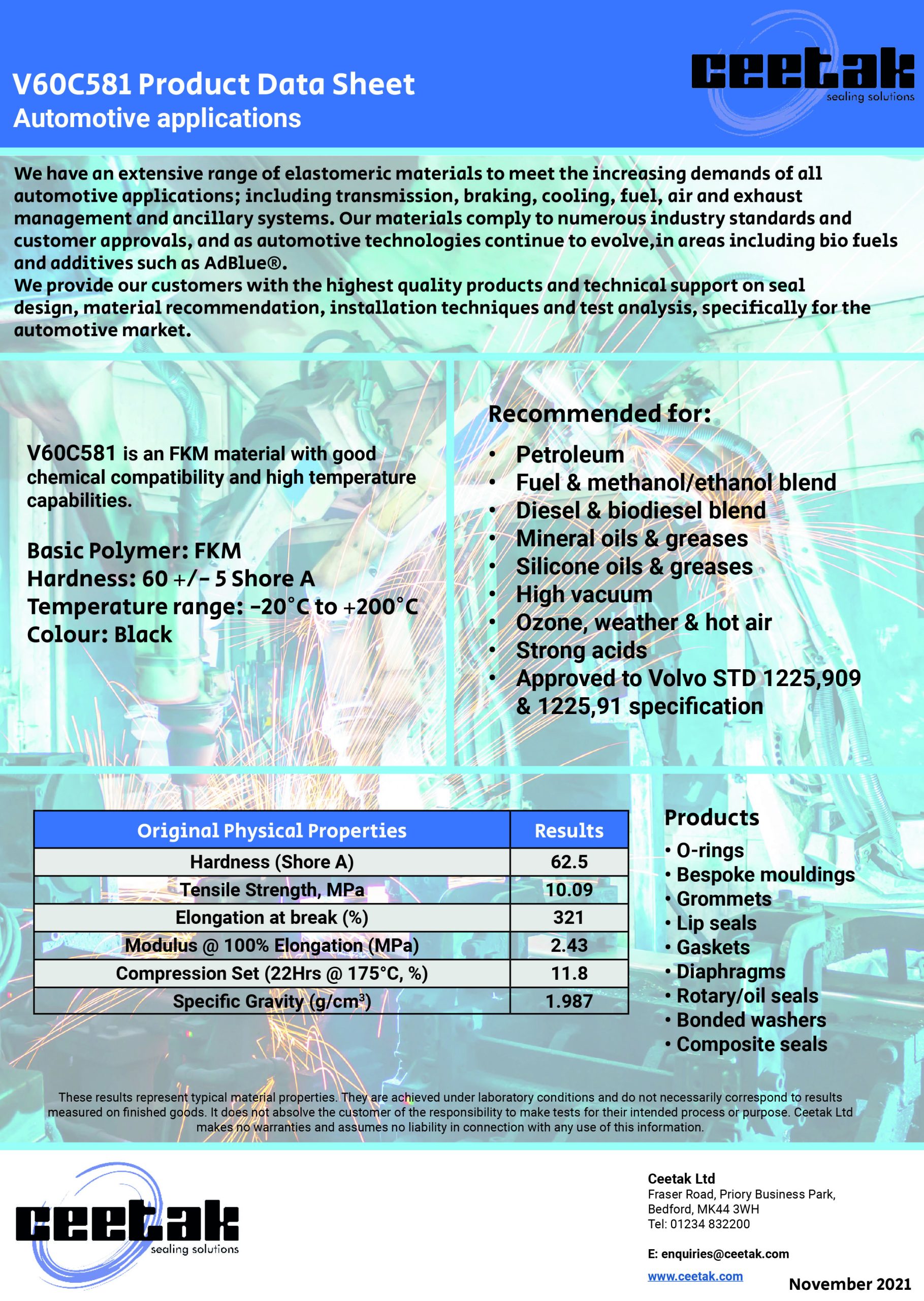

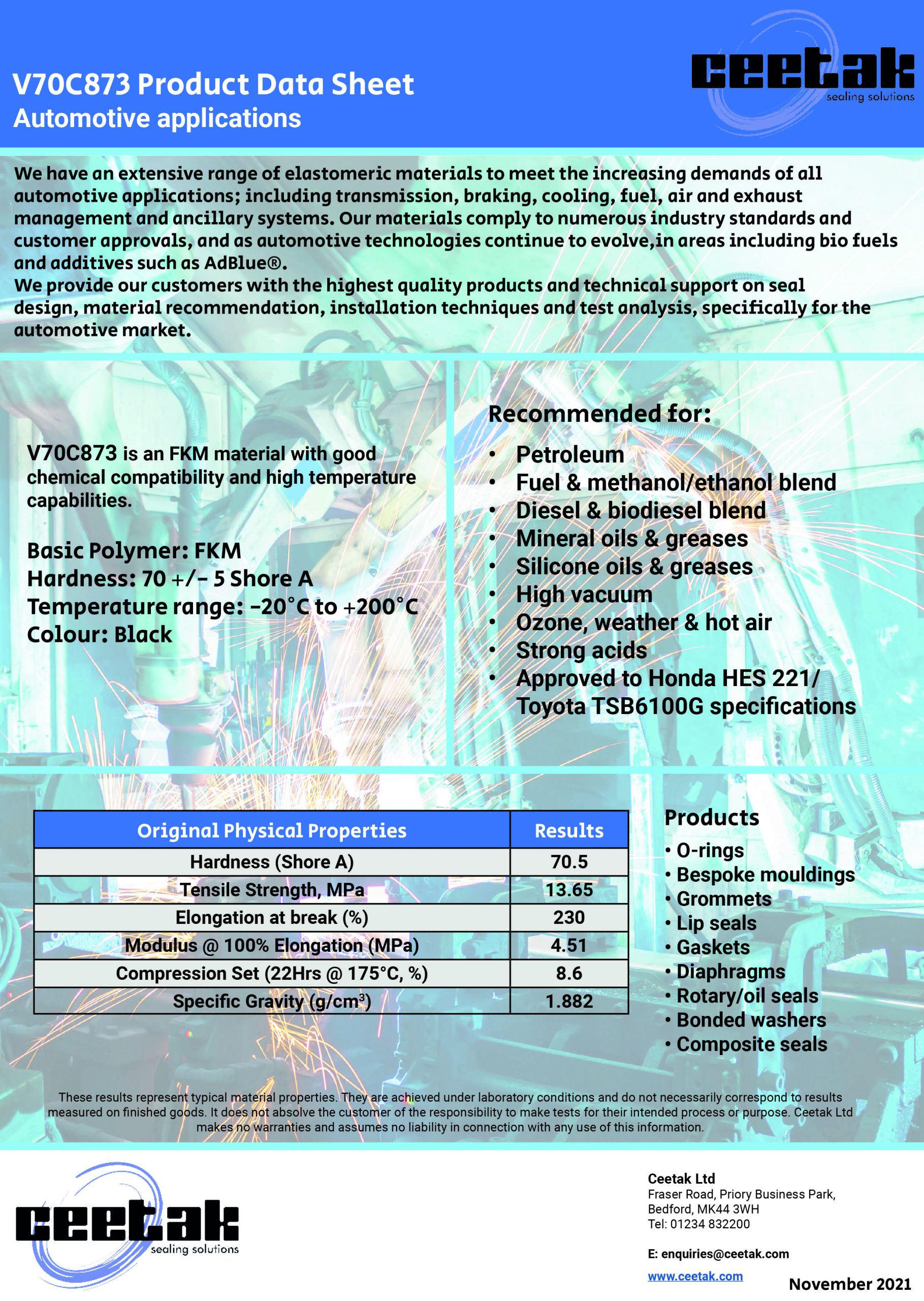

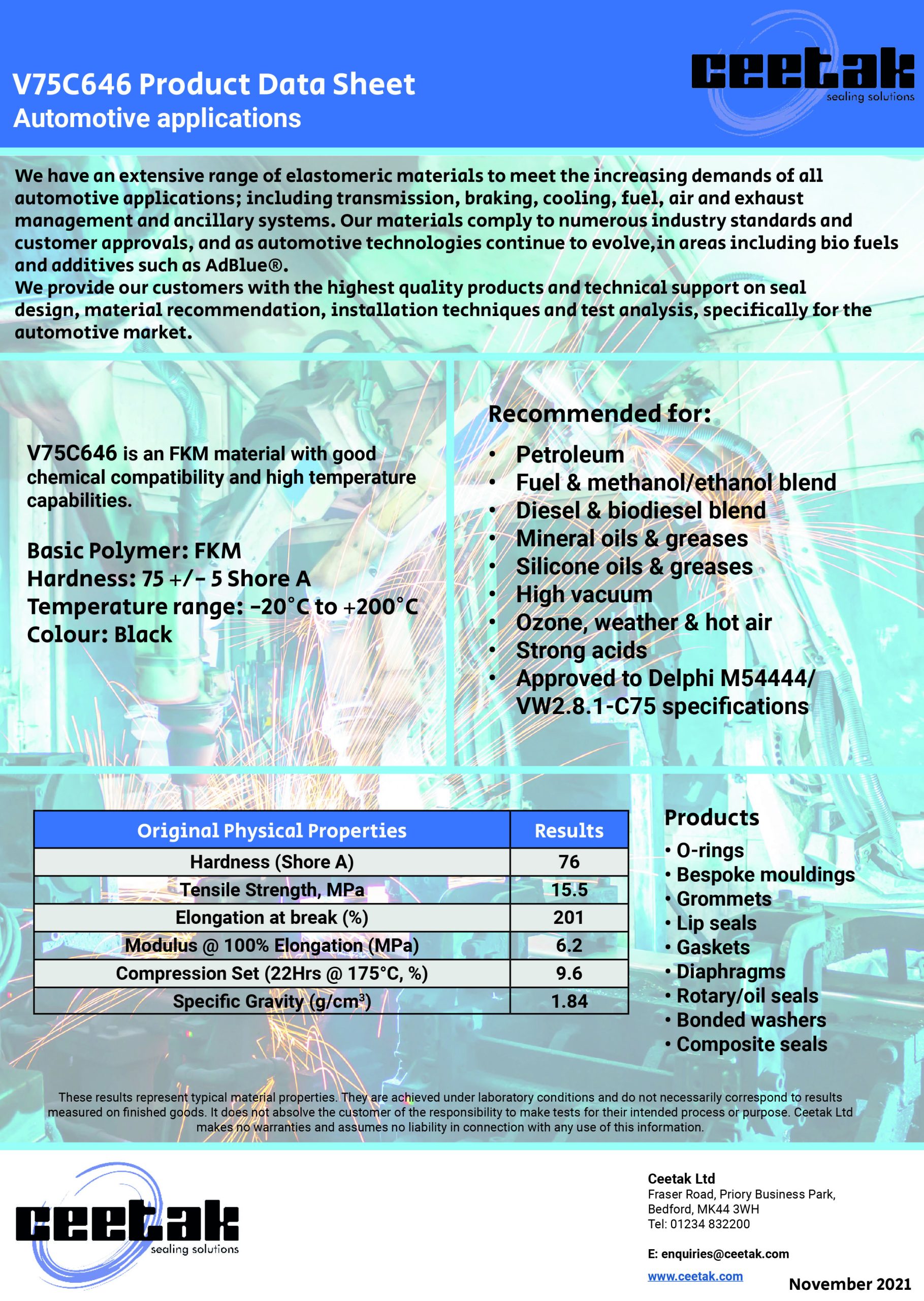

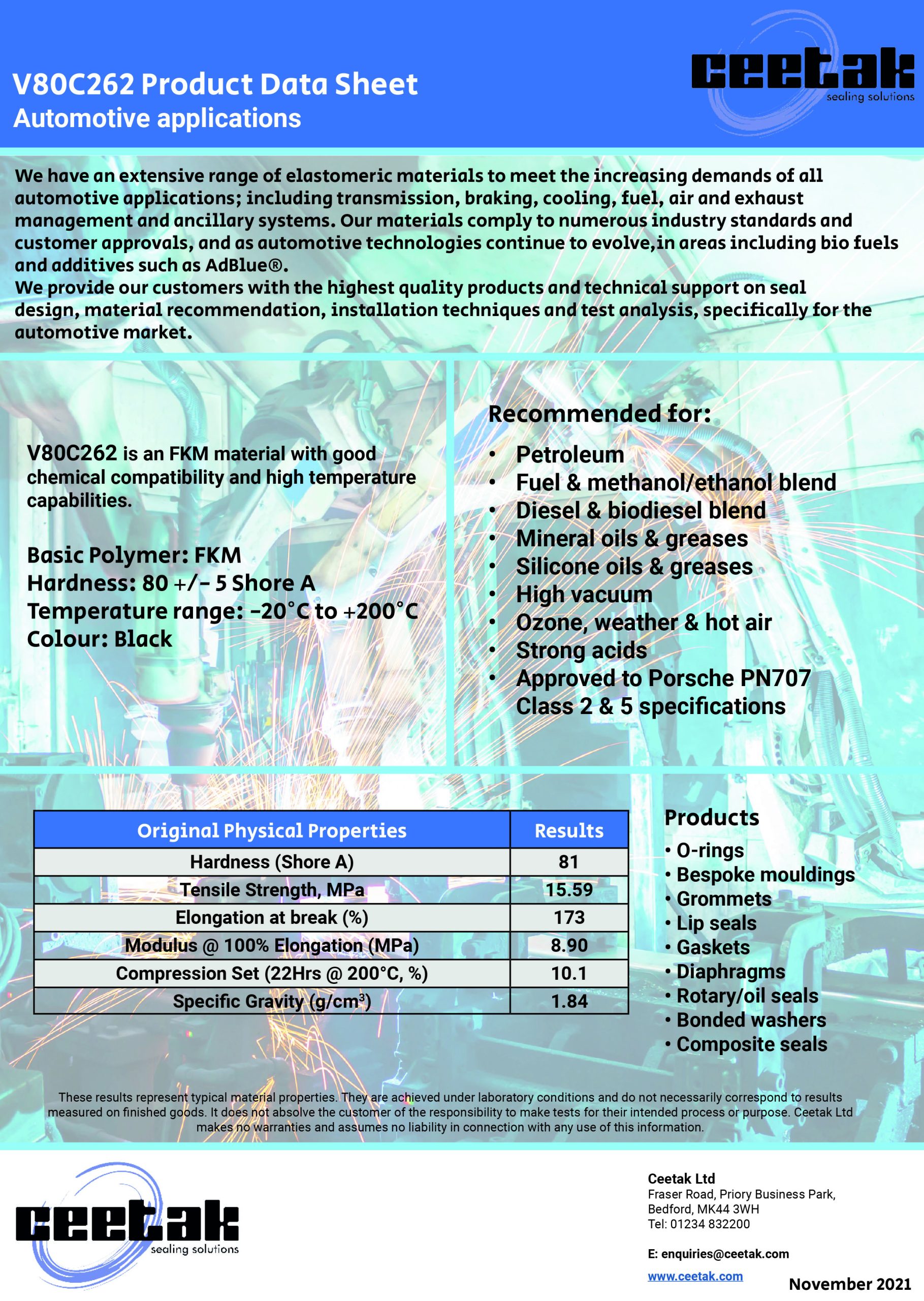

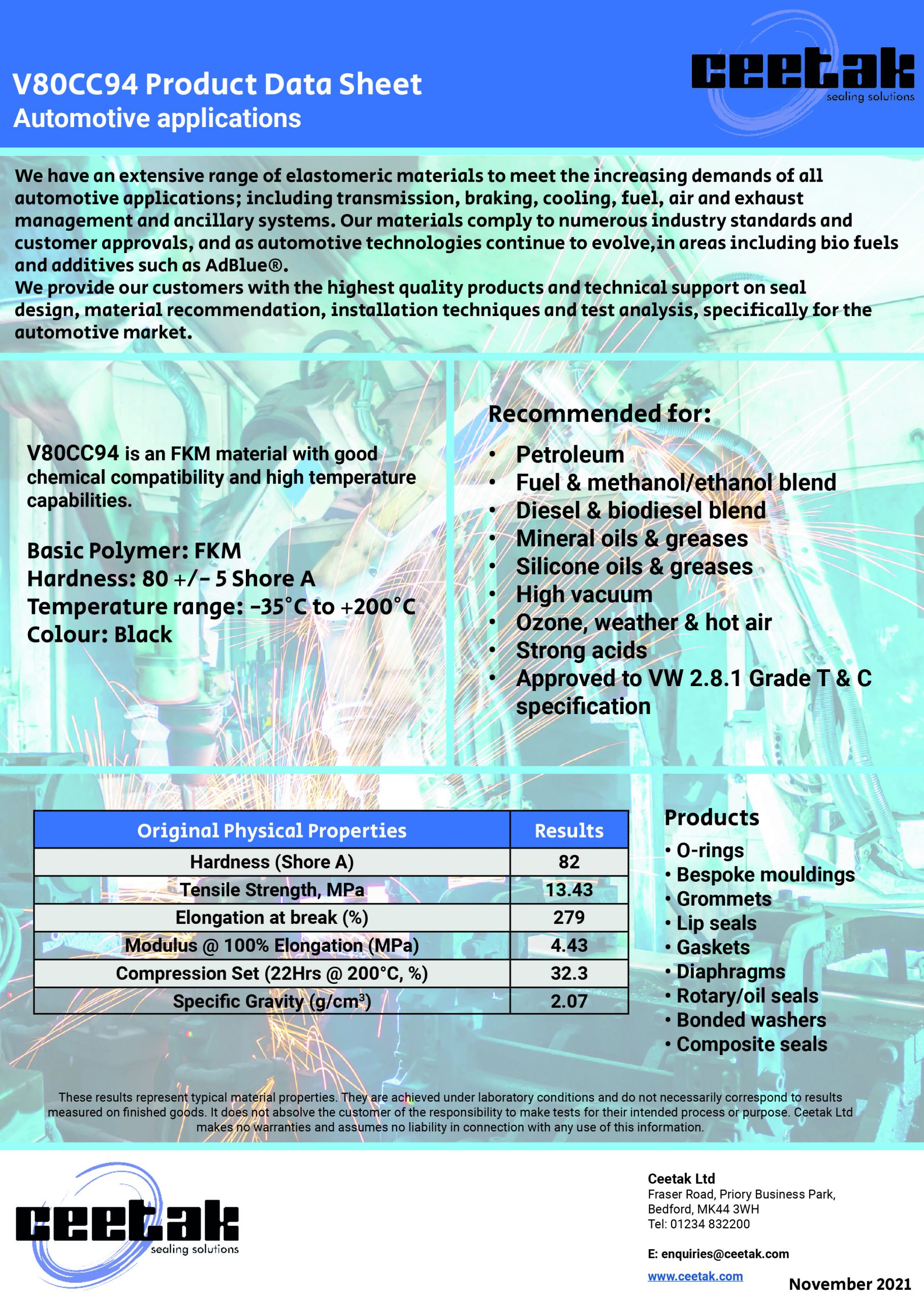

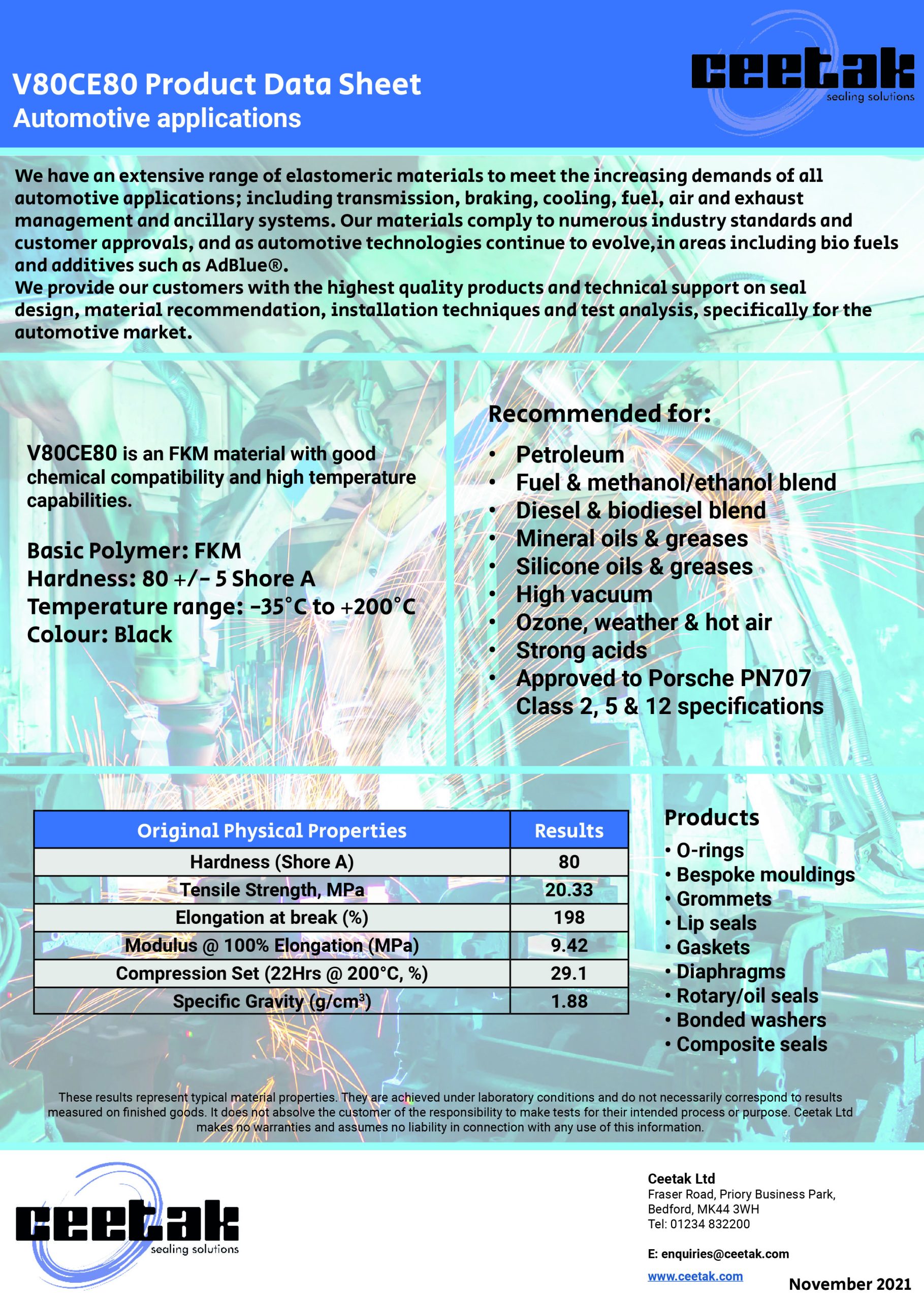

Seals for high static or pulsating pressure and high-speed rotary applications. Seals designed from a range of material grades suitable for all modern E5 to E100 fuel grades, diesel and biodiesel, LPG, selective catalytic reduction (SCR) exhaust systems, gas and diesel powered after treatment systems (AdBlue®).

Braking systems

Materials suitable for DOT3, 4 and 5 fluids, seals designed and manufactured to the highest standards to maximise life expectancy of system critical components.

Cooling & lubrication systems

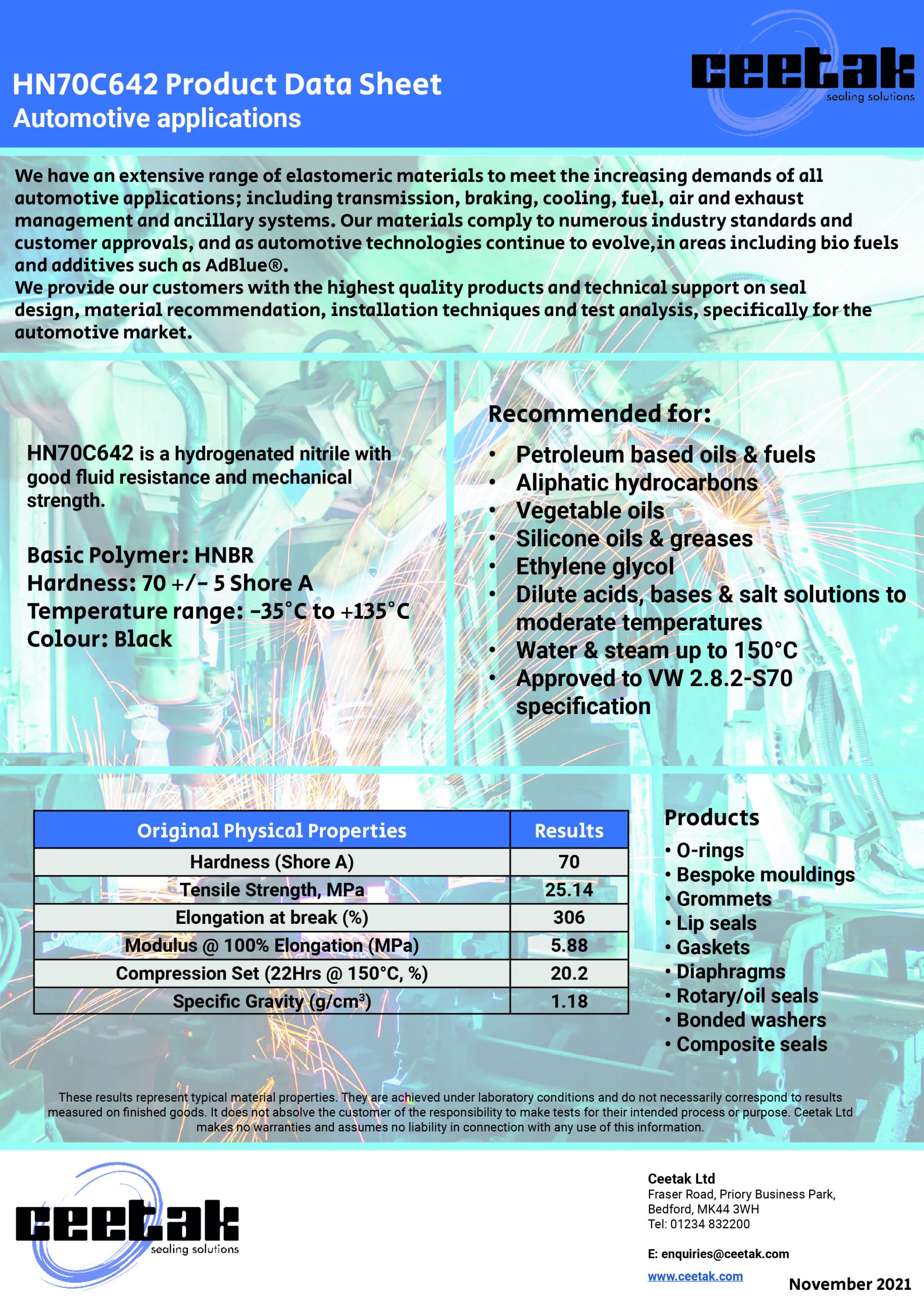

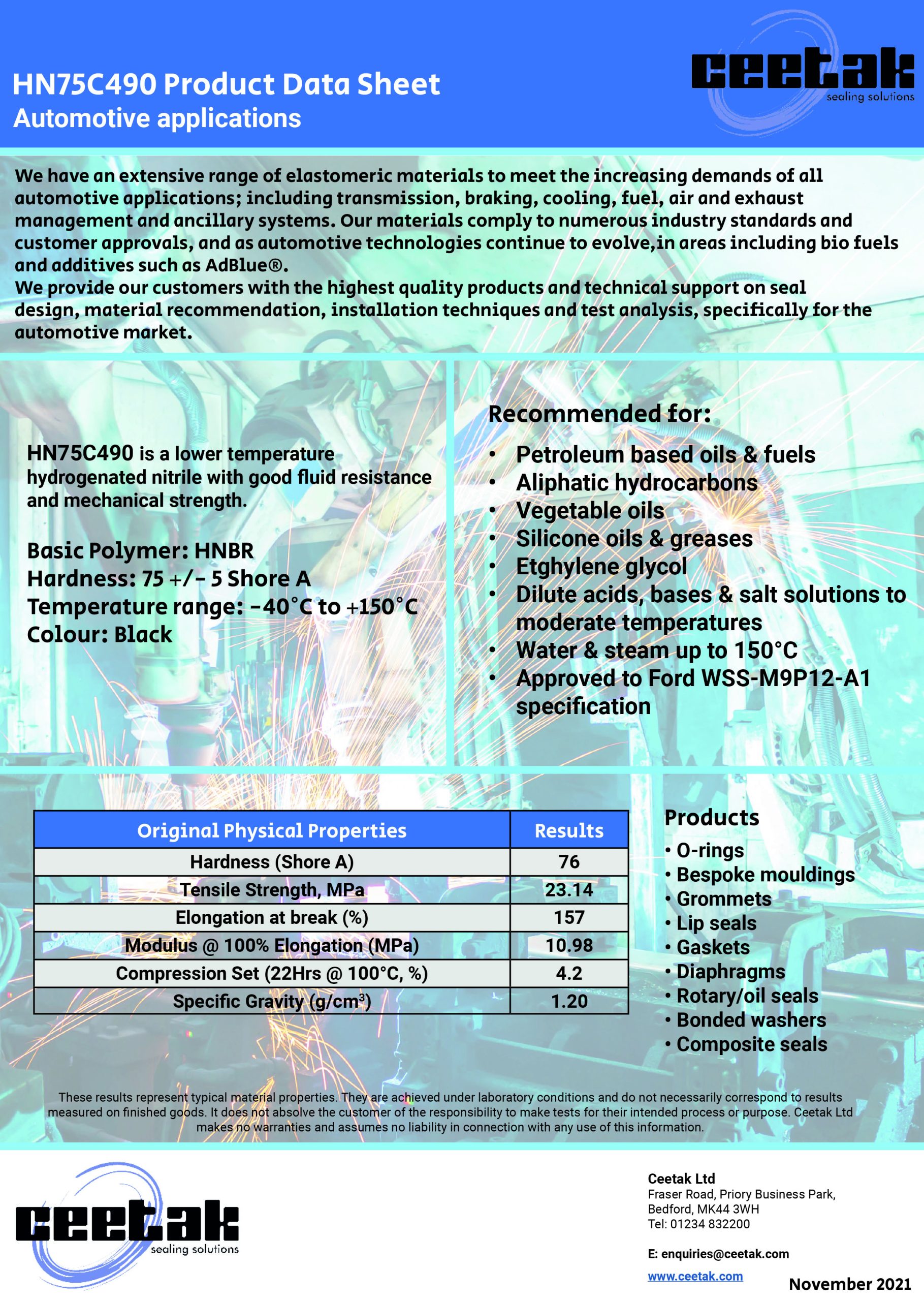

We have superior material grades for mineral oil and water/glycol cooling systems to meet the wide spectrum of temperature ranges required in these applications. Materials to seal against the demanding environment of synthetic based Polyalphaolefin (PAO) and ester-based oils for electric motor systems.

Transmission

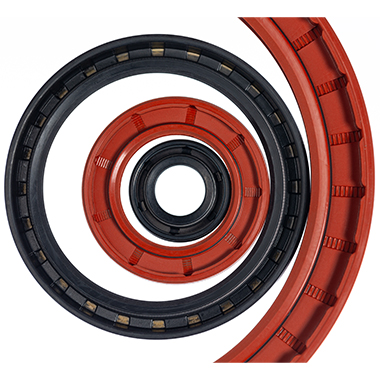

Rotary seals for high-speed applications manufactured in PTFE and elastomeric materials for next generation fluids.

Chassis & suspension

Seals manufactured in abrasion and load resistant, high strength materials. PTFE seals manufactured for hydraulic and pneumatic active suspension systems.

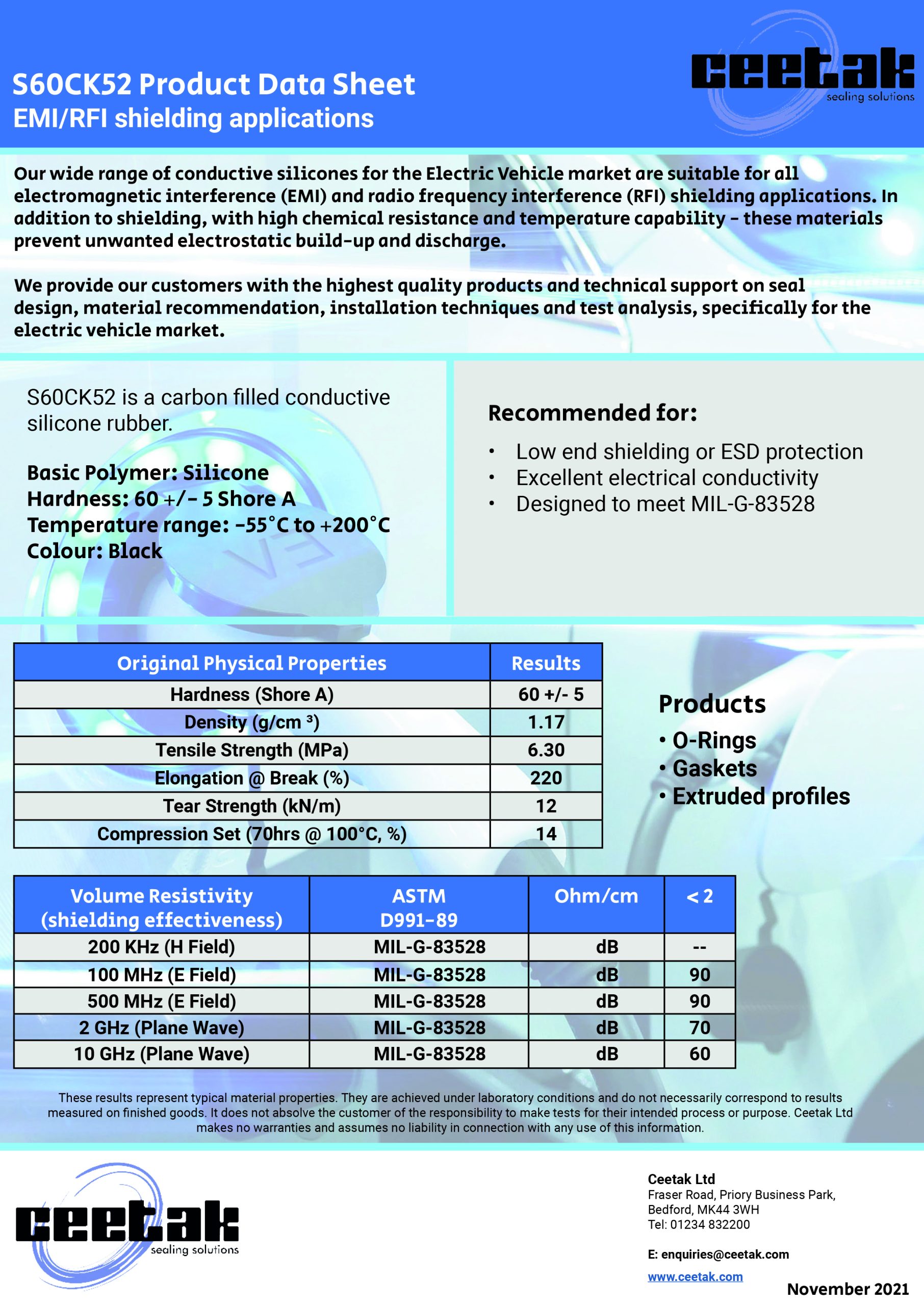

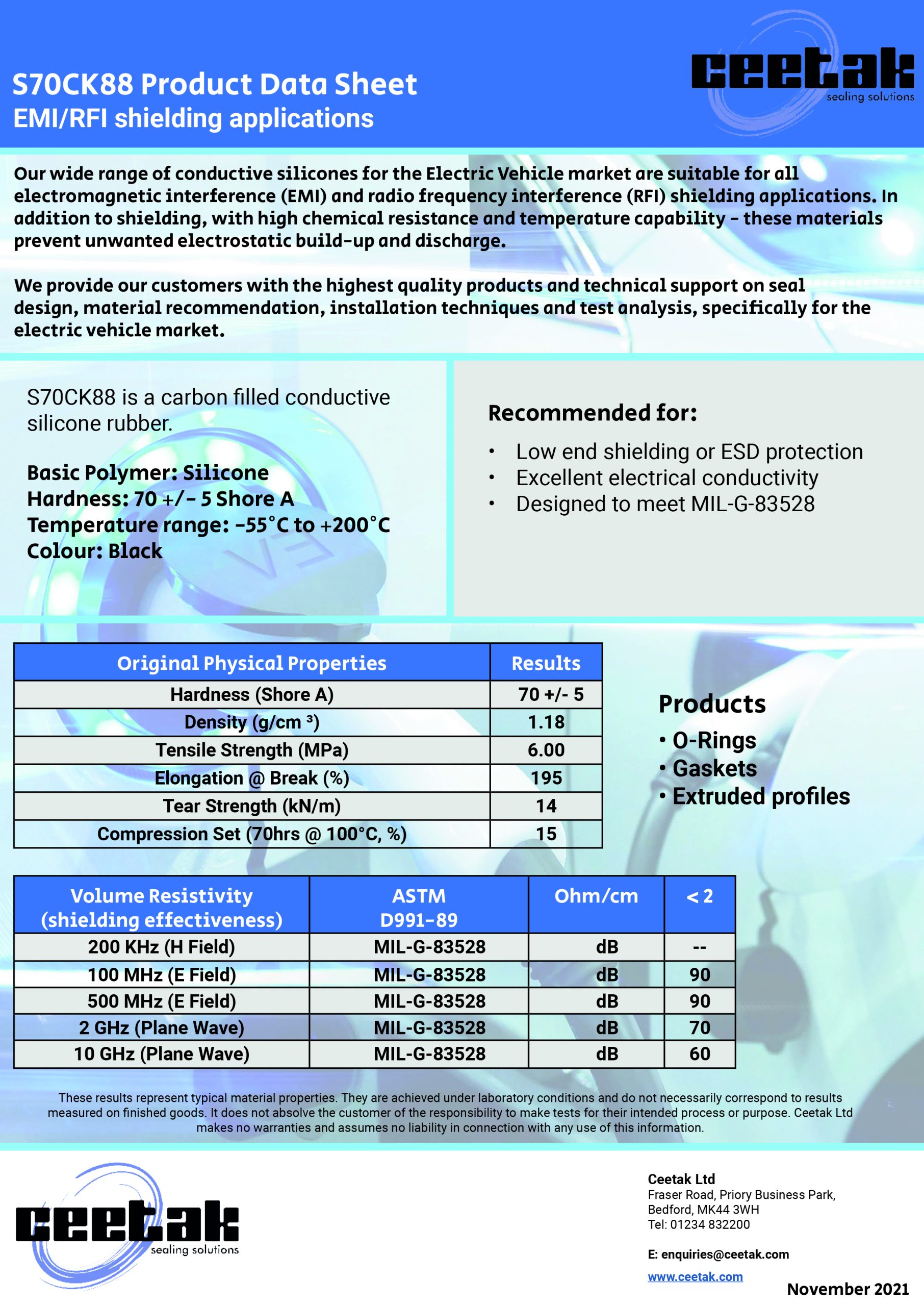

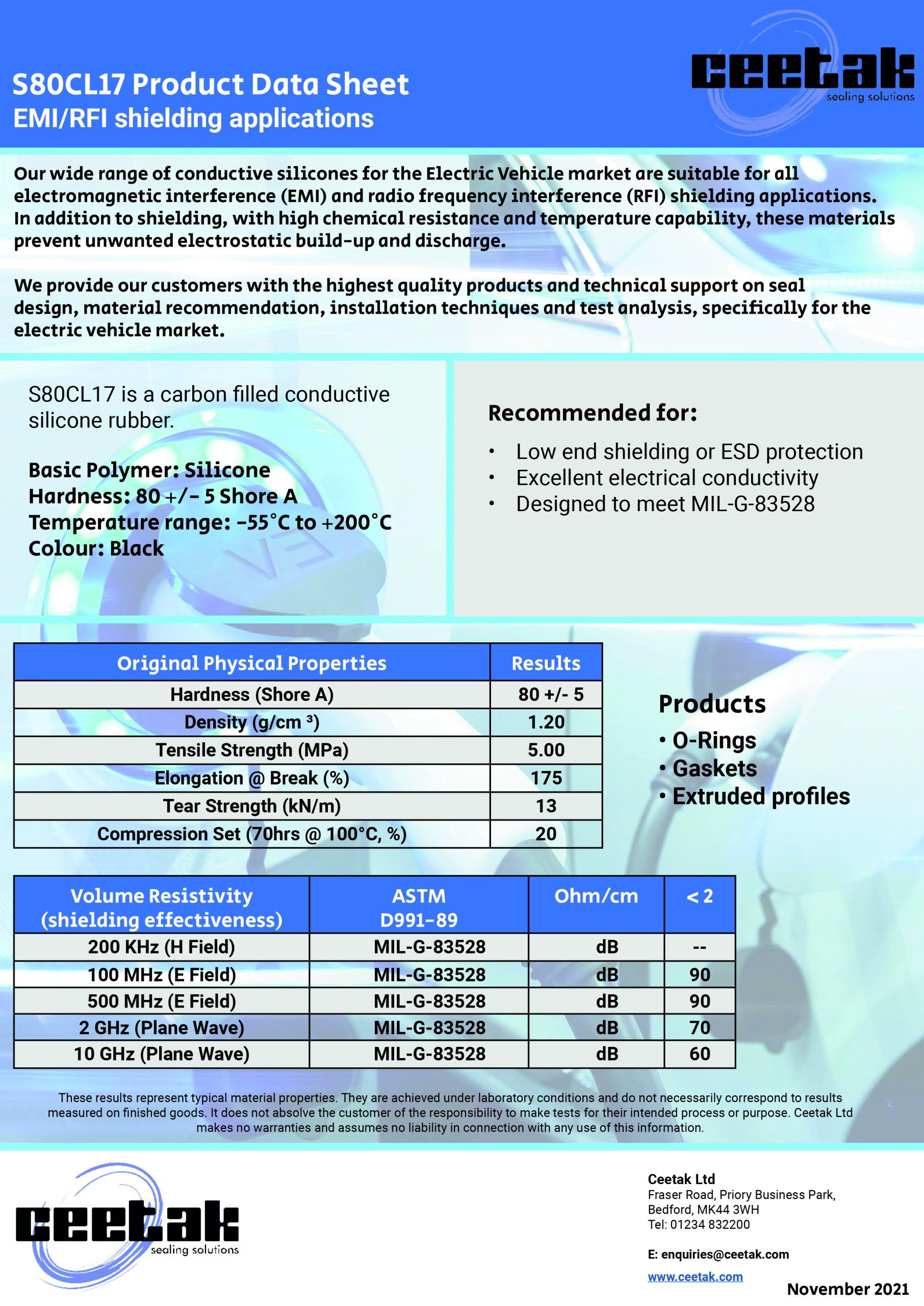

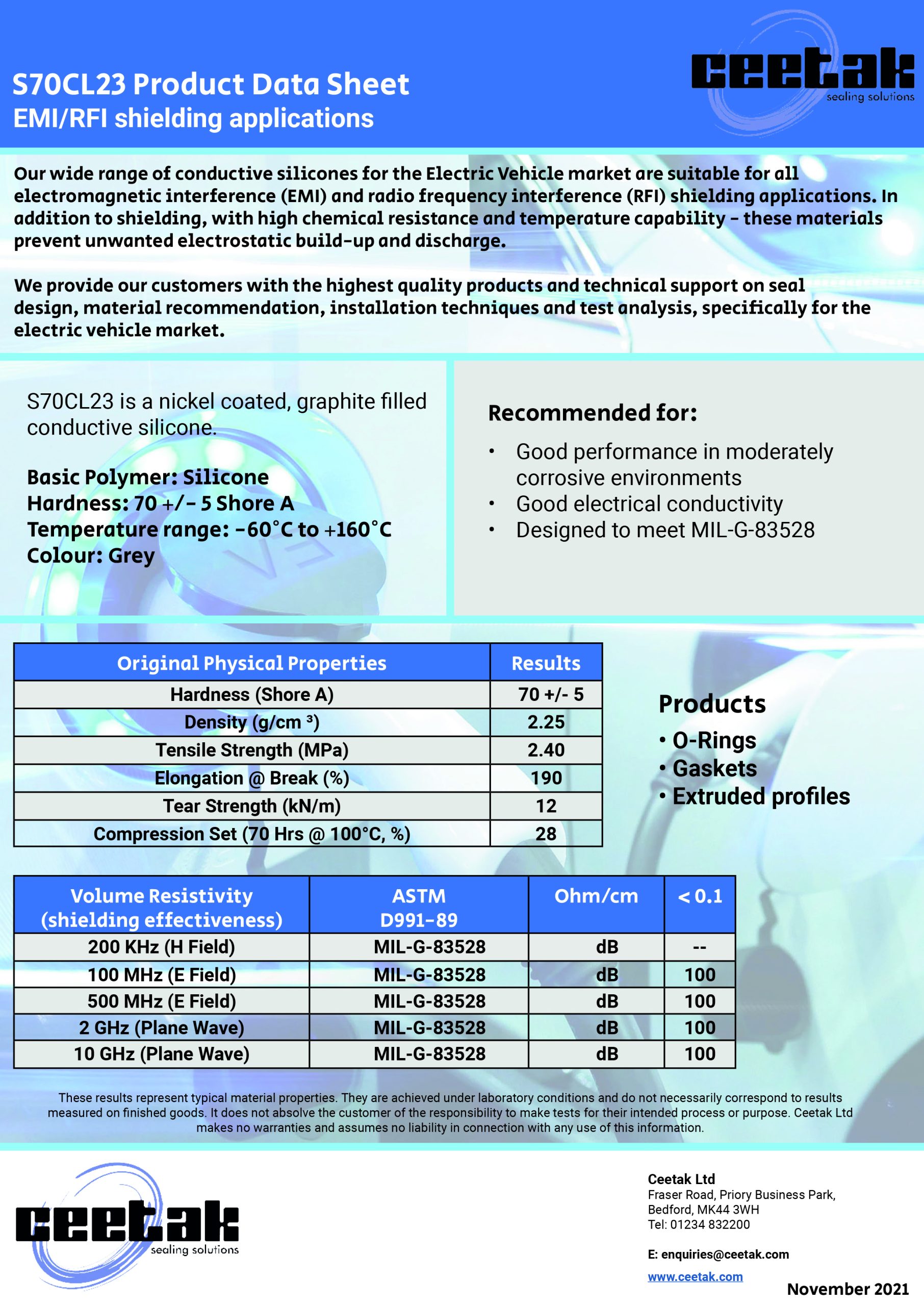

Battery & electronics

Innovative dielectric silicone grades for cable grommet and battery enclosure applications for BEV and PHEV’s. A tried and trusted Push-In-Place (PIP) gasket design for effective sealing of housings.

Screen and headlight wash systems

Low temperature EPDM grades for cost effective seal designs with resistance to modern detergents.

HVAC

EPDM, Neoprene (TRADENAME) and HNBR grades for resistance to modern Freon based refrigerants with extended life expectancy in HVAC seal designs.

Hydrogen

Seal designs and materials suitable for hydrogen fuel cell vehicles and hydrogen internal combustion engines (ICE).

Our engineers use 3D CAD and FEA simulation software to design and replicate automotive seal performance before finalising each seal design; incorporating significant feature and critical function elements for integration with customer mating parts. We offer material development and testing, and a component endurance testing service.