High speed Rotary seals for electric vehicles

The electric vehicle industry is growing; global manufacturing and registrations of electric vehicles is increasing exponentially each year. Our engineers have extensive experience in designing seals for automotive applications, but we still find new challenges involved in sealing components within hybrid, hydrogen fuel and full battery powered electric vehicles.

The application

Our customer has over 30 years’ experience of providing pioneering technologies globally to the mobility industry. This established company is a supplier of powertrain solutions for electric and hybrid vehicles, additionally traditional internal combustion power engines.

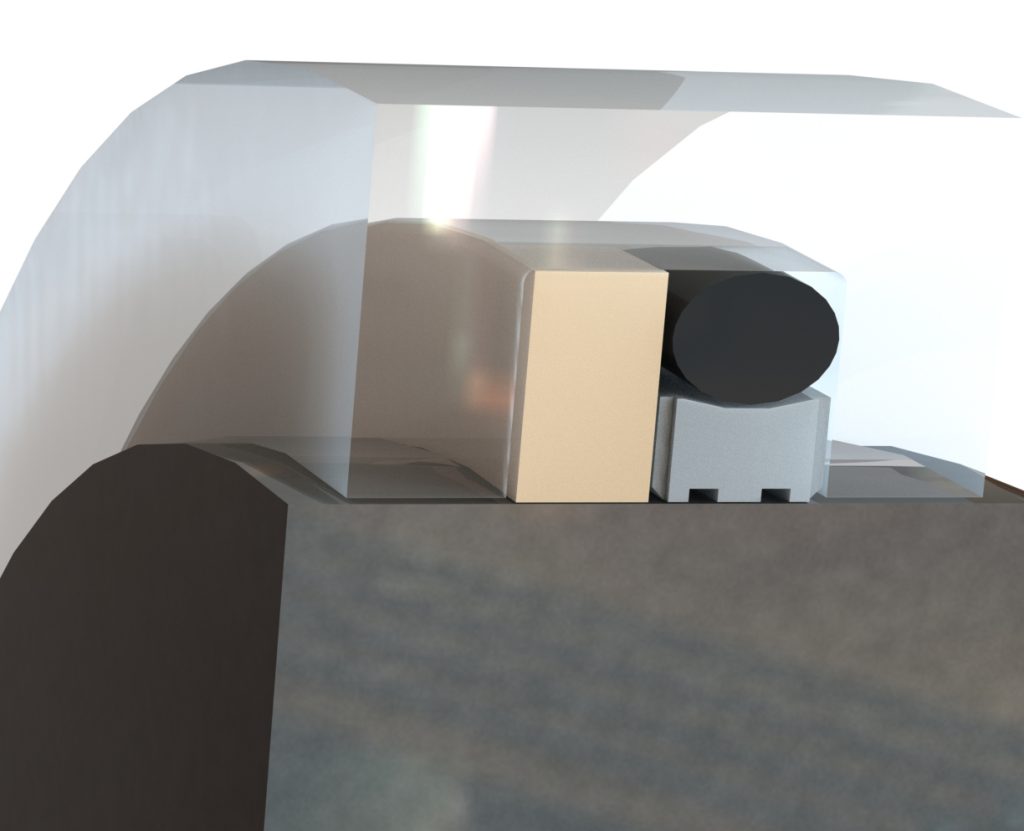

Their team of powertrain development experts approached our engineers for a rotary shaft sealing solution for the gearbox within an electric vehicle. The position of the seal was required between the wet transmission and dry e-motor, and pressed into a bulkhead housing.

The sealing lip runs on the surface of the transmission rotor shaft and pressed radially by a tension spring onto the shaft. Additionally, it required a dust lip to provide protection against environmental dirt and debris on the dry motor side.

The shaft and housing dimensions were all fixed by the customer. However, they provided a full dimensional, surface finish, pressure, temperature and media specification. This enabled our engineers to review and propose a bespoke seal design

Our sealing solution

The application media was a synthetic oil. This is relatively standard for an automotive application. However, because of the maximum working temperature, FKM (Viton) was the elastomer material to meet the required range.

As with many applications within electric vehicle gearboxes, the shaft speed was particularly high at 8500 RPM. Typically, with these high speeds, seal design needs to ensure minimal friction to ensure the service life required.

Our application engineers designed a bespoke, double lipped spring energised seal.

On the dry e-motor side, the rubber lip was designed to act as a dirt and dust excluder, with slight clearance from the shaft to avoid friction. This prevents damage to the seal and unnecessary wear to the rotary system as a whole.

In the wet transmission side, it was imperative that the oil was kept away from the e-motor with the same minimal friction requirements. As a result, our engineers have designed the seal with an inlaid PTFE lip with 15% graphite fill. It was energised with spring to ensure force which achieves ultimate shaft sealing performance.

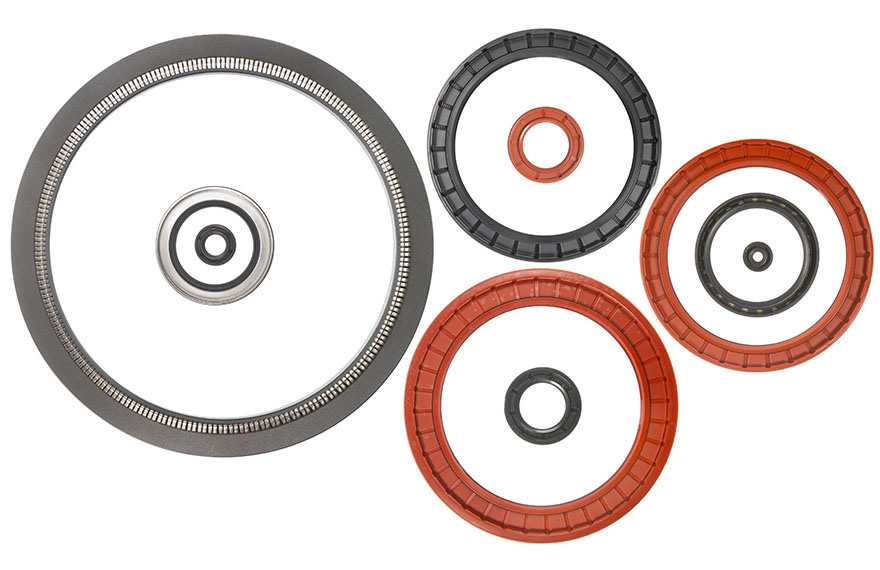

Read more about our rotary seals HERE