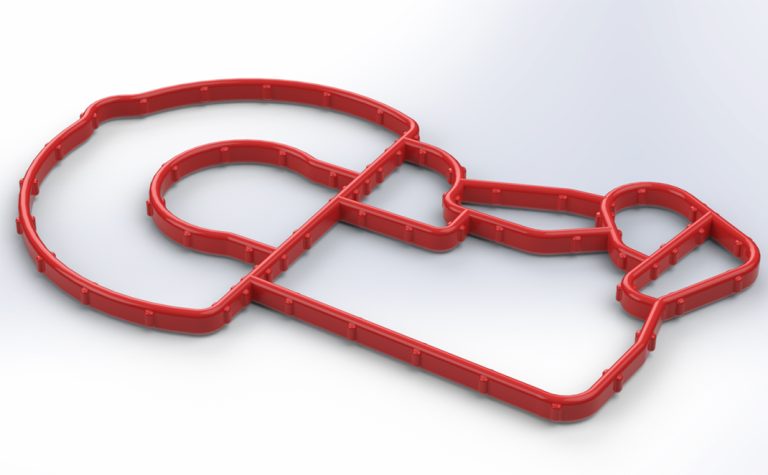

Precision Sealing for Naval Radar Slip Ring

Precision Sealing for Naval Radar Slip Ring The application Our customer is a globally recognised leader in the design and manufacture of advanced slip ring systems and contactless rotary joints. Their technology ensures the reliable transmission of power, data, and media across a wide range of rotating interfaces. Read more about how our engineers developed … Continued