PTFE Rotary Seal for Oil & Gas drilling tool

Our customer designs and manufactures a leading range of unique downhole technology and drilling solutions that contribute to a net zero energy industry.

The Application

A seal was required for the rod of a downhole drilling tool – a hydraulic dynamic (rotary) application. Our solution is a PTFE rotary seal. Read on to find out about more.

The application has a normal operating pressure of 500 PSI at 60 RPM, but maximum pressure can reach 6,500 PSI in static operation. Reverse pressure was unlikely in this application but the engineers wanted to ensure some level of resistance.

Two single acting seals were considered, but groove space is limited. Keeping the grooves closed is preferable for bearing strength.

The maximum operating temperature reaches 200°C and the application media drills mud and completion fluids (with wiper arrangement already installed).

Our Sealing Solution

Due to the pressure, temperature and chemical media parameters of this application, an elastomer seal selection was not suitable.

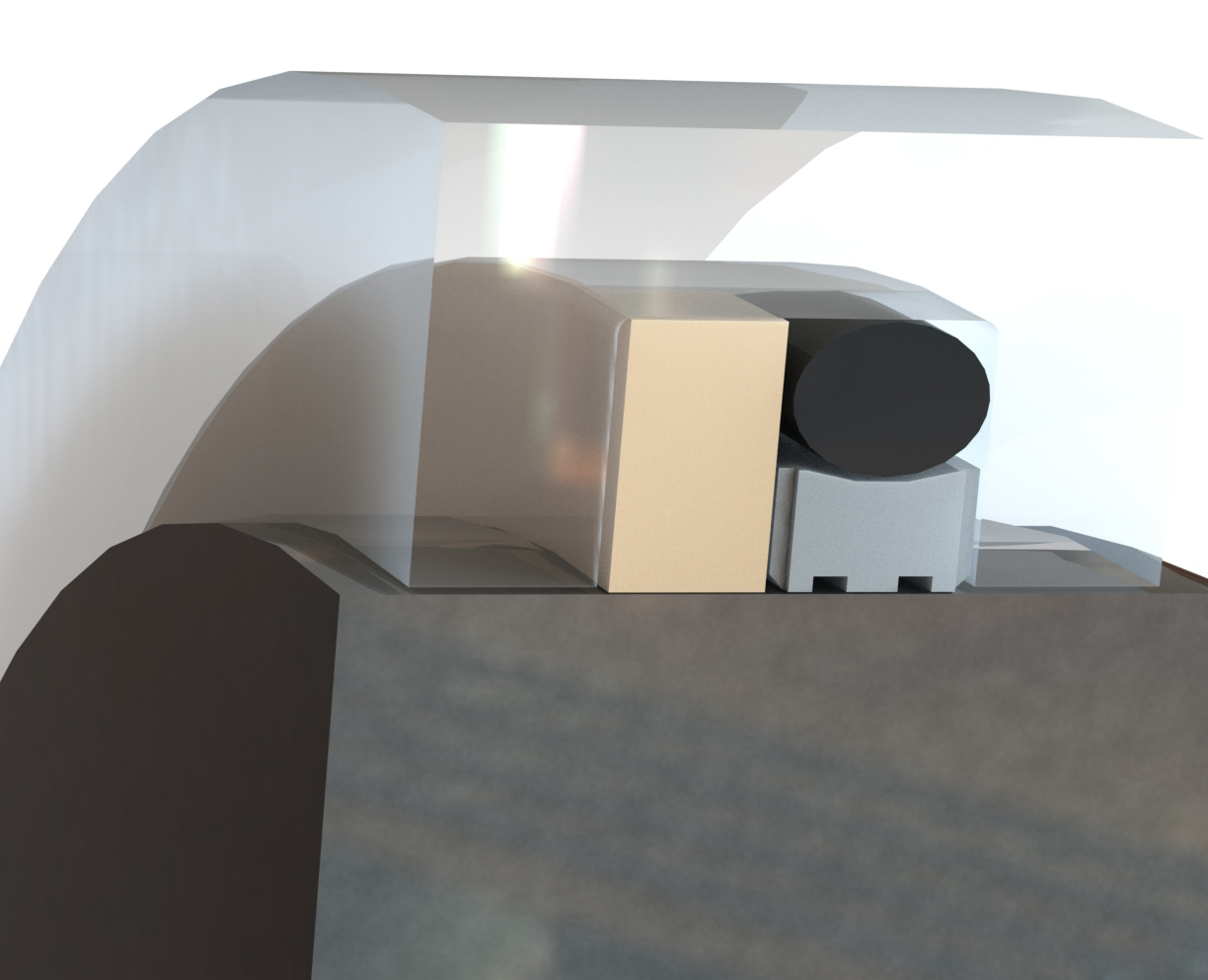

Our engineers selected our standard FTOR profile PTFE seal This is a double acting slipper seal ideally suited to hydraulic applications and capable of sealing under alternating pressure directions.

It’s ideal for sealing high pressure loads with slow to moderate rotational speeds. The PTFE rotary seal has side wall notches equally spaced, so the part can be fitted symmetrically either way.

The initial sealing force is provided by the elastomer O-ring. This is seated within a machined saddle and activated by system pressure to perform under high pressure demands. The central lubricating channel design ensures low friction and wear.

Additionally, the sealing set has been designed with a scarf cut PEEK back-up ring. This is to ensure stability and seal performance at maximum working pressure of 6,500 PSI.

Customer Satisfaction

Our customer tested the sealing arrangement at higher pressure (up to 10,000 PSI). Consequently, our customer is pleased it seals successfully over and above the application requirements. They have adopted this seal design for other sizes of parts in similar equipment.

Read more about our rotary seals HERE

The Application

A seal was required for the rod of a downhole drilling tool, and was a hydraulic dynamic (rotary) application.

Normal operating pressure was 500 PSI at 60 RPM, but maximum pressure could reach 6,500 PSI in static operation. Reverse pressure was unlikely in this application but the engineers wanted to ensure some level of resistance.

Two single acting seals could be considered, but groove space was limited. Keeping the grooves closed was preferable for bearing strength.

The maximum operating temperature could reach 200°C and the application media was drilling mud and completion fluids (with wiper arrangement already installed).

Our Sealing Solution

Due to the pressure, temperature and chemical media parameters of this application, elastomer seal selection was not suitable.

Our engineers selected our standard FTOR profile PTFE seal, which is a double acting slipper seal ideally suited to hydraulic applications and capable of sealing under alternating pressure directions.

It’s ideal for sealing high pressure loads with slow to moderate rotational speeds. The PTFE seal has side wall notches equally spaced, so the part can be fitted symmetrically either way.

The initial sealing force is provided by the elastomer o-ring (seated within a machined saddle and activated by system pressure to perform under high pressure demands). The central lubricating channel design ensures low friction and wear.

The sealing set was also designed with a scarf cut PEEK back-up ring to ensure stability and seal performance at maximum working pressure of 6,500 PSI.

Customer Satisfaction

Our customer tested the sealing arrangement at higher pressure (up to 10,000 PSI), and was pleased to find it sealed successfully over and above the application requirements. They have adopted this seal design for other sizes of parts in similar equipment.