Seals for cryogenic applications

Cryogenic sealing means controlling or sealing a media at very low temperatures. This process can be complex and advanced, and spans a range of markets; from pharmaceutical, chemical and refrigeration, to automotive and electronics.

What are low temperatures for seals?

A typical industrial sealing system operates in the realms of a stable temperature rating. This is often sufficient for elastomer seals to cope with most of the time. For example, a general pump application running at -20°C to +80°C in air or water would be perfectly suitable for a sealing solution manufactured in nitrile (NBR) elastomer. However, if that temperature specification dropped to -196°C in liquid Nitrogen, the overall sealing solution would need adapting dramatically. Therefore, a more advanced polymer solution is needed.

This is because general elastomer groups such as NBR, FKM, & VMQ are not suitable to perform at very low temperatures. This is due to the chemistry of the elastomers at a molecular level.

All elastomers need a particular chemical makeup to be able to withstand a temperature range of the application required. However, many global elastomers on the market are not rated much more below -70°C. This means they’re not a viable choice for cryogenic applications with temperatures way below -70°C (often requirements reach below -196°C).

Types of cryogenic sealing solutions

Specialised sealing solutions are required for cryogenics conditions. Our engineers utilise a range of more advanced seal polymers to solve the most demanding and critical application setups.

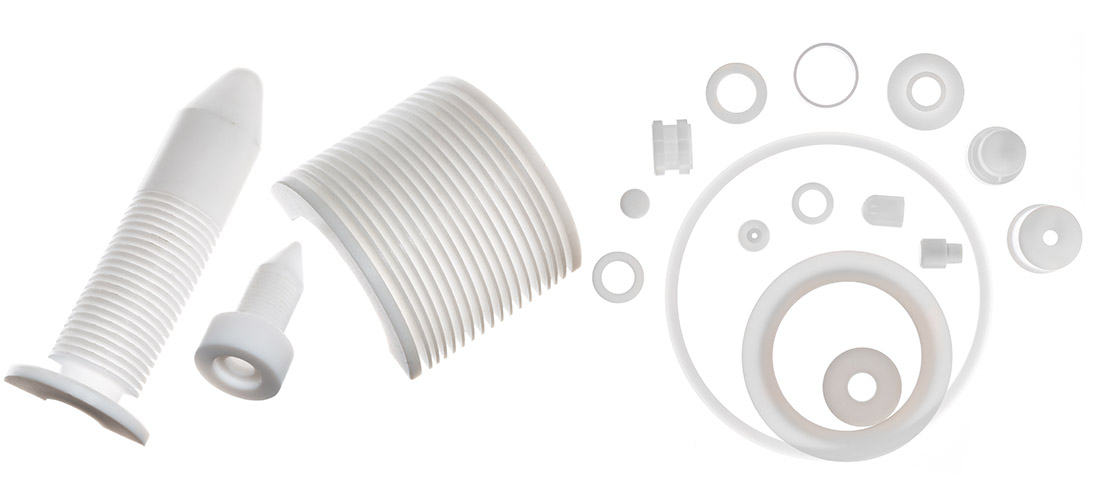

PTFE has an outstanding temperature rating of -260°C to +260°C and low friction characteristics. It is also regularly used in conjunction with a metal spring energiser.

The spring energiser acts to maximise the sealing force at the seal contact points and to maintain a tight seal. This is the case even when the very low temperature conditions are attempting to contract the seal away from the mating surfaces.

Other common polymers suitable are UHMPWE and PTCFE for more specific applications.

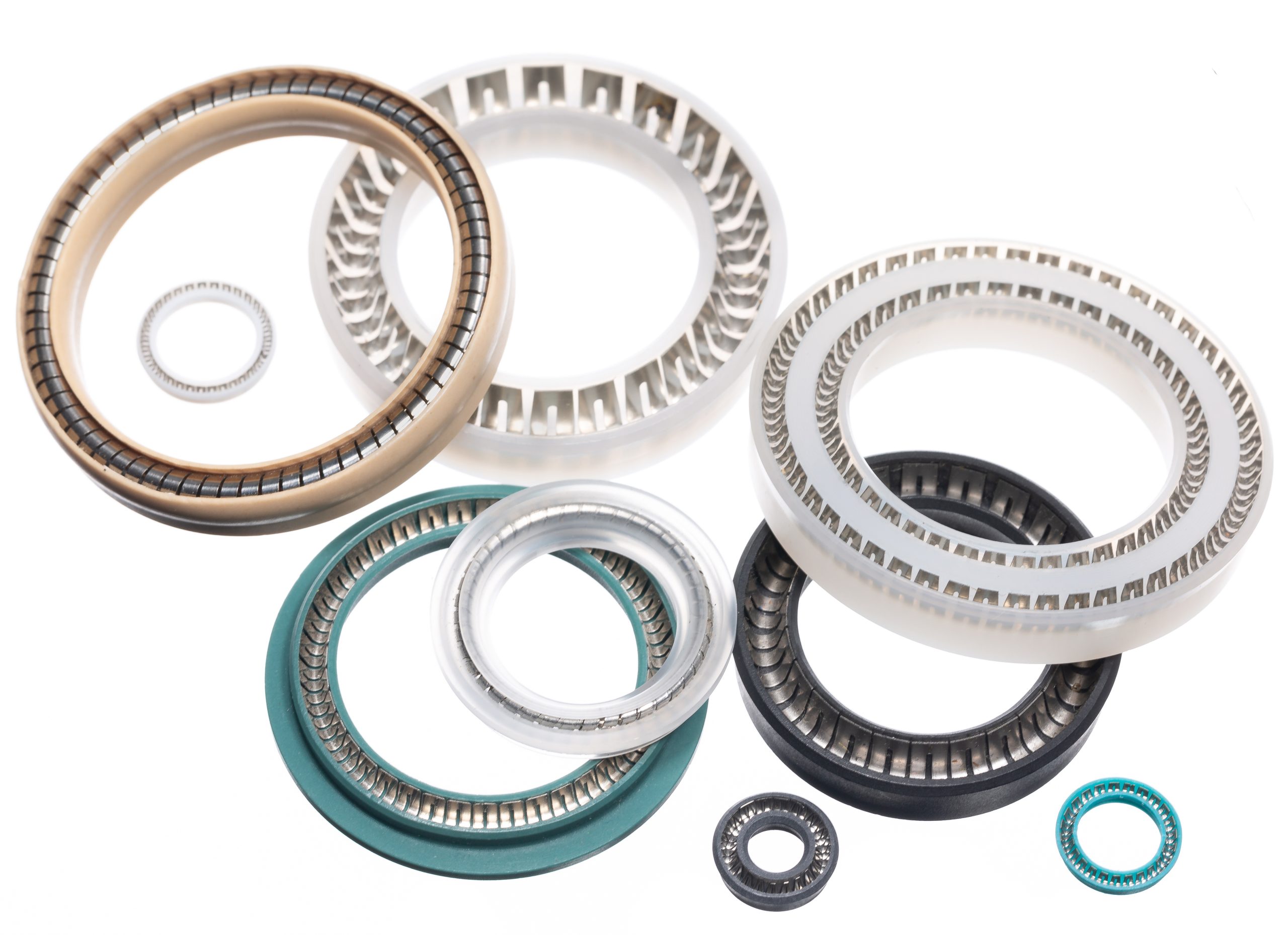

Our seals for cryogenic applications

We offer a range of cryogenic sealing solutions for various markets and applications including; pumps, engines, couplings, cylinders and many more.

Read about our full range of engineered materials HERE

What are low temperatures for seals?

A typical industrial sealing system will operate in the realms of a stable temperature rating, which is often sufficient for elastomer seals to cope with most of the time. For example, a general pump application running at -20°C to +80°C in air or water would be perfectly suitable for a sealing solution manufactured in nitrile (NBR) elastomer. However, if that temperature specification dropped to -196°C in liquid Nitrogen; the overall sealing solution would have to be adapted dramatically to a more advanced polymer sealing solution.

This is because general elastomer groups such as NBR, FKM, & VMQ are just not cut out to perform at very low temperatures, and this is attributed to the chemistry of the elastomers at a molecular level.

All elastomers need a particular chemical makeup to be able to withstand a temperature range of the application required, but current global elastomers on the market are not rated much more below -70°C. This means they are not a viable choice for cryogenic applications with temperatures way below -70°C (often requirements reach -196°C or lower).

Types of cryogenic sealing solutions

Specialised sealing solutions are required for cryogenics conditions. Our engineers utilise a range of more advanced seal polymers to solve the most demanding and critical application setups.

PTFE is often a go-to material due to its outstanding temperature rating of -260°C to +260°C and low friction characteristics, and is often used in conjunction with a metal spring energiser.

The spring energiser acts to maximise the sealing force at the seal contact points and to maintain a tight seal, even when the very low temperature conditions are attempting to contract the seal away from the mating surfaces.

Other common polymers suitable are UHMPWE and PTCFE for more specific applications.

Our seals for cryogenic applications

We can offer a range of cryogenic sealing solutions for various markets and applications including; pumps, engines, couplings, cylinders and many more.