Design Engineering

Product range includes static, rotary and linear sealing solutions.

Our experienced team of engineers will collaborate with you to design and develop advanced sealing solutions for applications in some of the most demanding industry sectors.

Product range includes static, rotary and linear sealing solutions.

Seal selection is recommended based on application conditions.

Approved materials, recommended or developed to customer specifications.

FEA, 3D printing, rapid functional prototyping and materials testing.

Design Engineering for all industries

Working with global customers for over 50 years on their sealing solutions, we design a comprehensive range of products.

Our expertise include static, rotary and linear seal designs from simple O-rings through to more challenging and complex sealing solutions.

Application Engineering

We support customers at all stages of their project with our bespoke service. We test, measure, and iterate to ensure the right seal and material is selected, and is the optimum choice for application conditions.

A customer might already know the specification of their seal design, or perhaps need full design support with a brand new sealing solution for a project. Either way, our step-by-step process ensures all elements, from prototype to production, are considered and tested.

Materials Expertise

In an ever changing world of technology, our experienced team will recommend and develop the best material selection to meet customer specifications.

Collaborating with world-class material suppliers and compounders, our engineers ensure current industry standards are met and we remain at the forefront of material development.

Our extensive range includes all the core elastomer types and engineered plastic materials, virgin and filled PTFE, TFM, PEEK and UHMWPE.

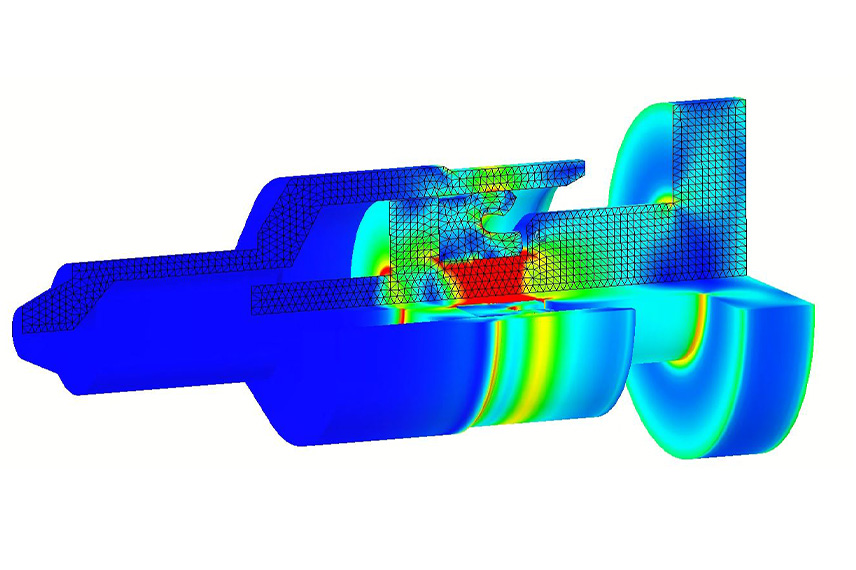

Simulation and Validation

With over 100 years of combined seal design experience, we understand the importance of cost-effective and high performing products.

Our in-house Finite Element Analysis (FEA) simulation, 3D CAD designs and 3D prototyping services ensure customers are given expert technical support, with the option for designs and materials to be adapted if needed.

We can provide samples, often with a short turnaround, meaning rapid decisions on design can be made prior to full production.