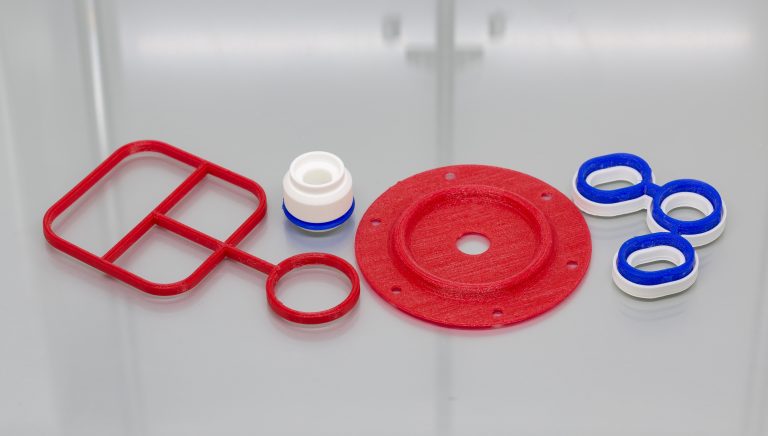

We design and supply seals for applications throughout the whole vehicle; including transmission, braking, cooling, fuel, air and exhaust management, battery, cable and ancillary systems. We offer low quantity custom designed parts with rapid turnaround to meet the challenging demands of our Motorsport customers.

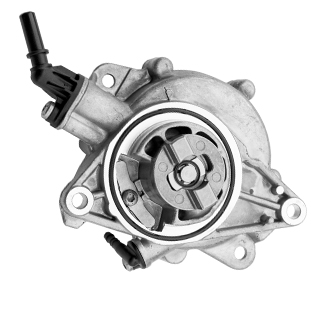

Braking systems

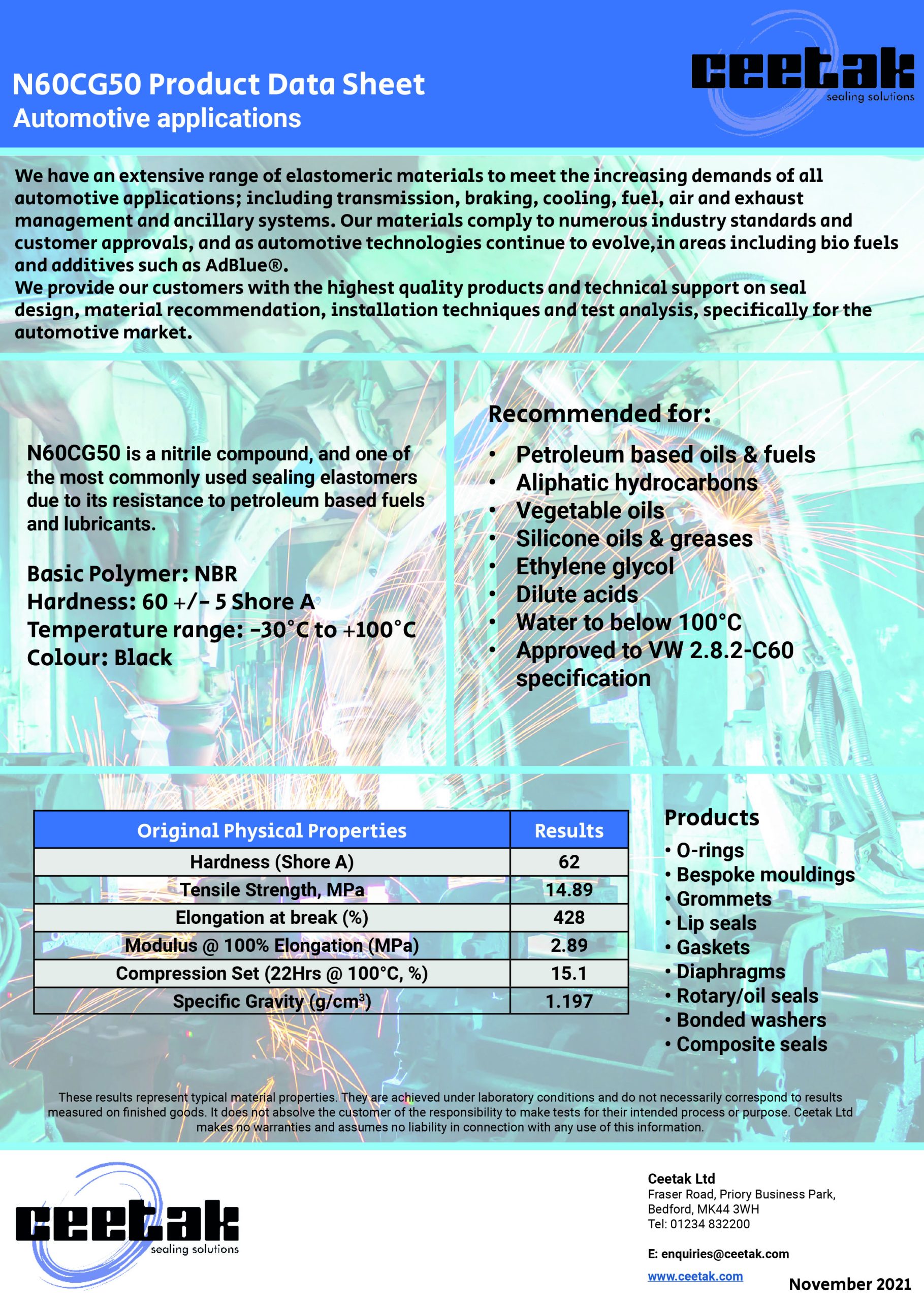

Materials suitable for DOT3, 4 and 5 fluids, seals designed and manufactured to the highest standards to maximise life expectancy of system critical components. Seals can be designed to minimise hysteresis and improve brake feel

Transmission

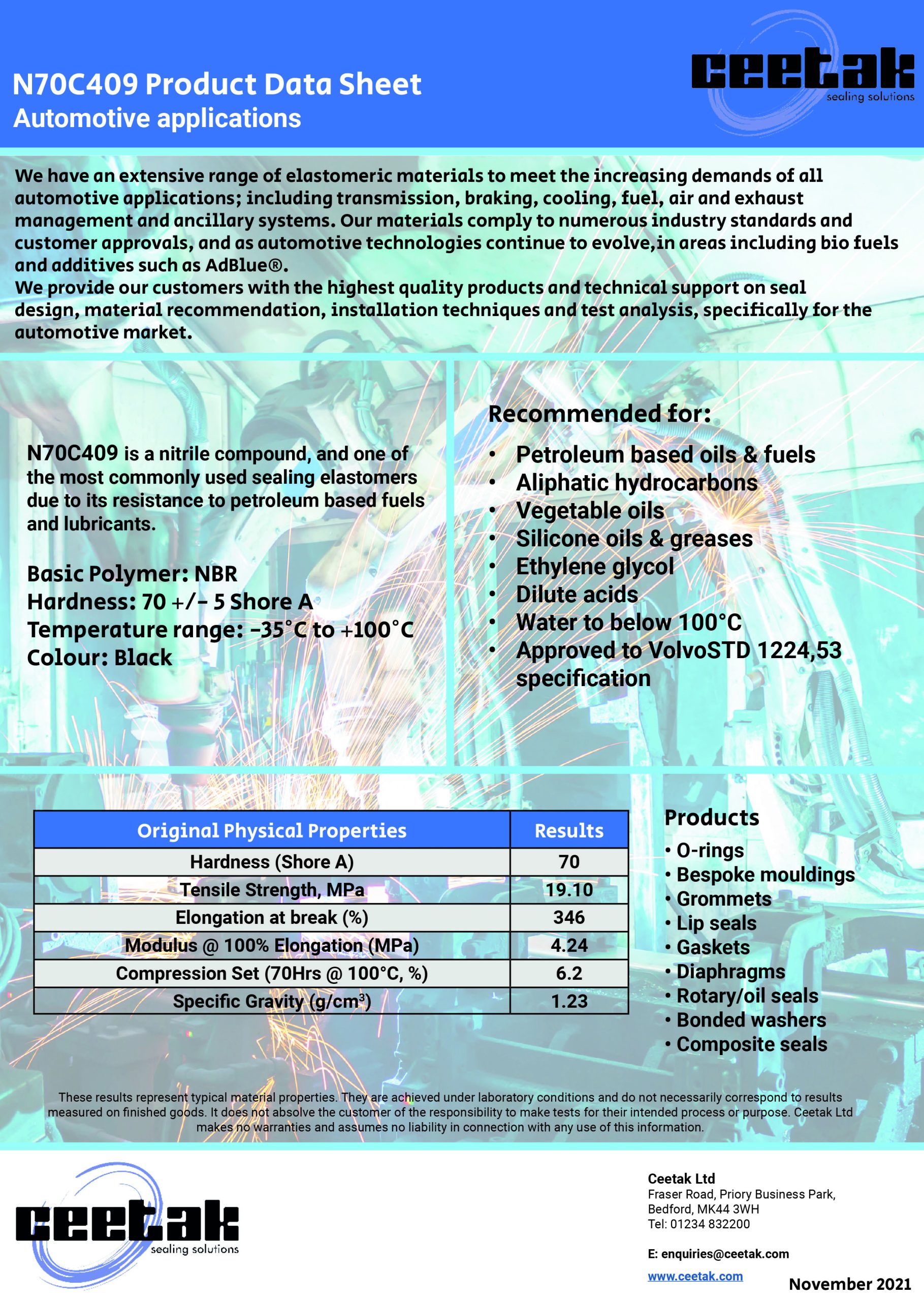

Rotary seals for high-speed applications manufactured in PTFE and elastomeric materials for next generation fluids. Low friction designs help to allow highest possible performance while maintaining long wear life and prioritising efficiency of the assembly.

Battery & electronics

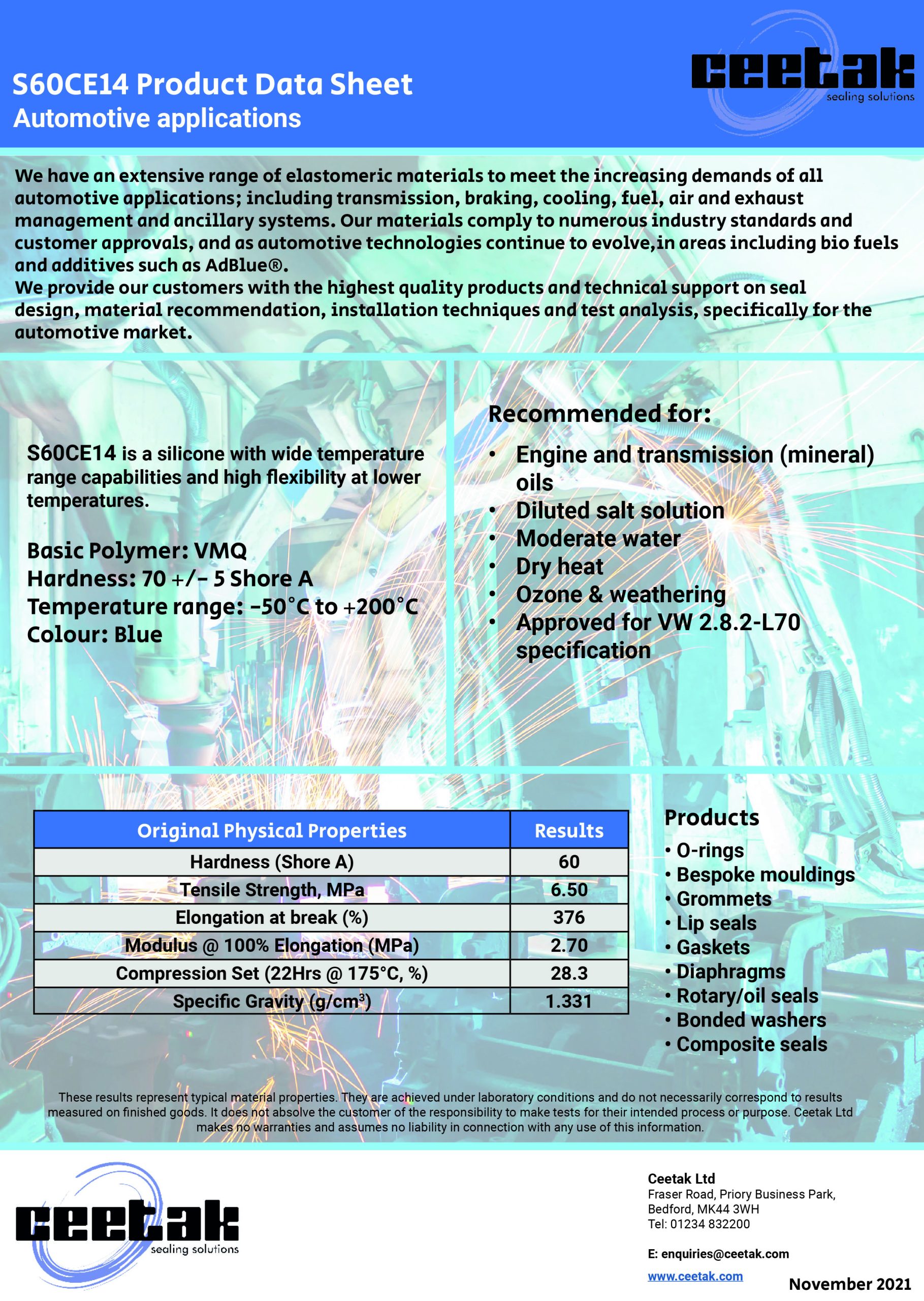

Innovative dielectric silicone grades for sealing of electric components ensures minimal electrical resistance through sealing areas . A tried and trusted Push-In-Place (PIP) gasket design for effective sealing of housings.

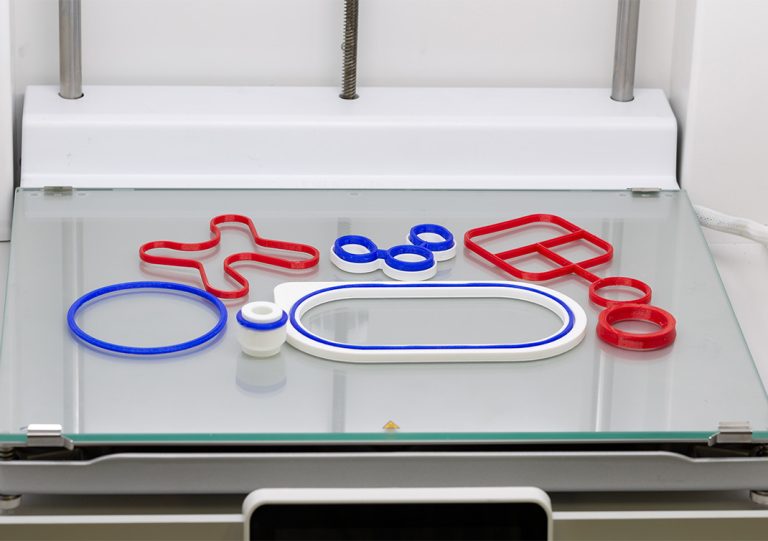

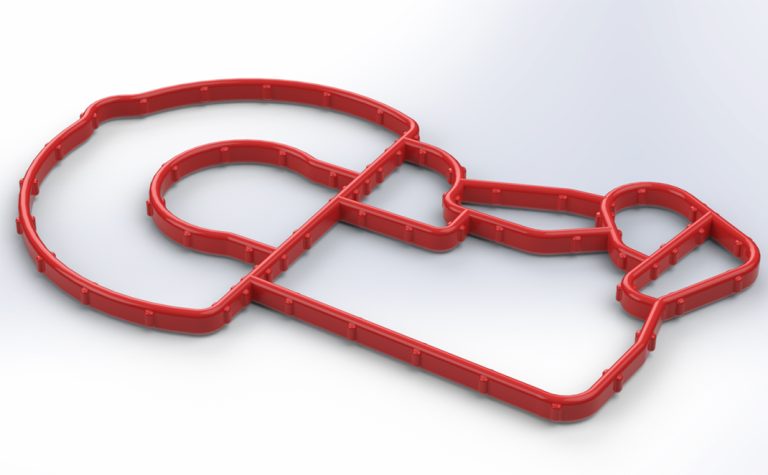

Our engineers use 3D CAD and FEA simulation software to design and replicate seal performance before finalising each seal design; incorporating significant feature and critical function elements for integration with customer mating parts. We offer material development and testing, and a component endurance testing service.