Fluorosilicone & Silicone Rubber (FVMQ/VMQ/LSR)

Silicone (VMQ/LSR) and Fluorosilicone (FMQ) are Q-Group of elastomers where silicone is the main molecular chain and has one of the widest temperature range capabilities from a single elastomer compound.

What is FVMQ/VMQ/LSR?

VMQ (vinyl methyl silicone rubber) is a member of the Q-Group of elastomers where silicone is the main molecular chain and has one of the widest temperature range capabilities from a single elastomer compound.

Highly flexible, even at low temperatures, it has many compounding and processing options, including the ability to colour the compound more easily than with the other elastomer groups.

FVMQ (fluoro vinyl methyl silicone rubber, or fluorosilicone) adds fluorine at the molecular level to reduce the number of chemical reactions that can take place and significantly improves the chemical resistance compared to MVQ (although hot air capability is lowered).

LSR (Liquid Silicone Rubber) is a heat cured elastomer which is processed in a two-part liquid form, sometimes with additional ingredients such as pigments. With similar final properties to high consistency rubber (HCR) silicone, injection moulding in liquid form allows the production of intricate and tight tolerance precision parts, often required in the automotive industry. It has inherent biocompatibility and stability making it also ideal for use in biomedical and pharmaceutical applications.

When to use FVMQ/VMQ/LSR?

With a price range sitting between NBR and FKM materials, VMQ is often selected when either high/low temperature requirements exceed NBR capabilities, but fluid compatibility does not require FKM. VMQ also exhibits high physiological inertness (tasteless, odourless and non-toxic), inherent resistance to bacteria and fungal growth, and has high purity with low levels of extractables making it ideally suited to applications in the food, pharmaceutical and biomedical arenas. With better chemical resistance, FVMQ can be more widely specified, at a notably higher cost. All Q-Group materials have relatively poor mechanical properties, including tear strength and wear resistance, which coupled with a high coefficient of friction would generally mean it is only used for static applications.

With good cold temperature flexibility and very good resistance to ozone, weathering and UV radiation, VMQ is often used in applications where the seal is exposed to the environment, or under extreme cold conditions where a degree of flexibility is required. It has good dielectric properties and resistance to high molecular weight, chlorinated aromatic hydrocarbons (including flame-resistant insulators, and coolant for electrical transformers). With moderate water resistance, high purity and cleanliness, and compatibility with diluted salt solutions and animal and vegetable oils, it’s suitable for biomedical, food and beverage sealing applications. Temperature capability ranges from -54°C (-65°F) to +204°C (400°F) but special grades can reach as low as -115°C (-175°F) or up to 260°C (500°F). FVMQ is more chemically inert, providing improved fuel, mineral oil and low molecular weight aromatic hydrocarbon (such as benzene, toluene) resistance, but with a maximum temperature capability reduced to +175°C (350°F).

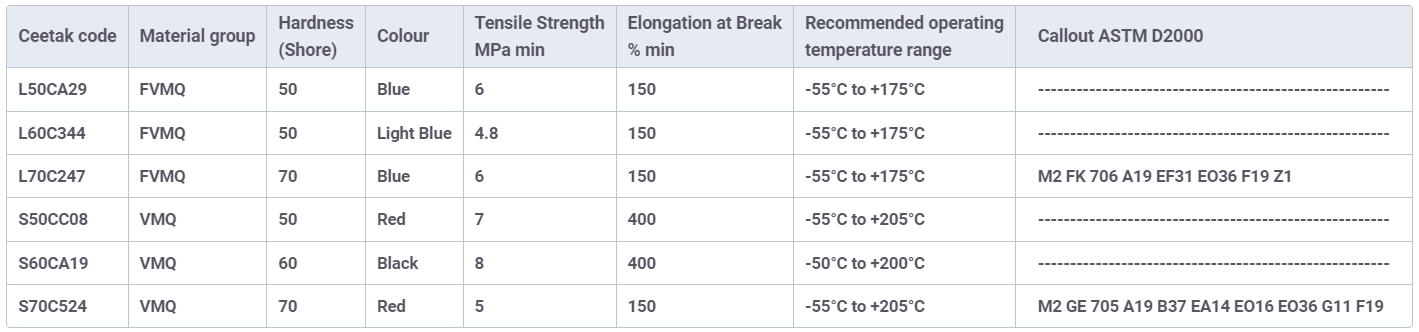

Standard FVMQ/VMQ/LSR materials

This is a small selection of our general purpose FVMQ/VMQ/LSR materials. Many more compounds are available and can be chosen to suit the specifics of the application.

The tensile strength and elongation are for specification purposes. Typical achieved values can be significantly higher.

Temperature range is general recommendation for static application in air. Temperature ratings are subject to full application review.