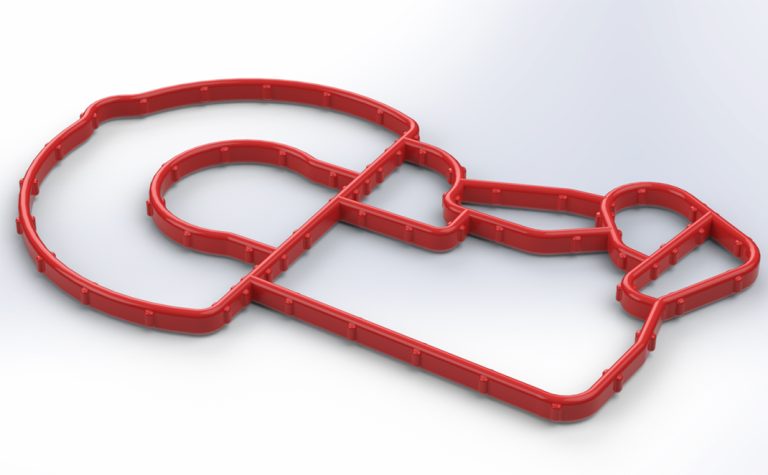

Moulded gaskets for an automotive application

An existing customer (an automotive manufacturer) approached our engineers with an application where they were experiencing failures of a seal designed and manufactured by another rubber seal provider. Here we explore more about our solution for a moulded gasket for this automotive application.

The application

This gasket is used within a valve housing in an automotive application. The original competitor gasket was experiencing failure at the “T-junction” areas of the seal. Therefore, our customer had experienced chronic failures of their existing design at high temperatures and high pressures.

A pulsating pressure of up to 50 Bar and temperatures up to 150°C provide an extreme environment for the seal. Consequently, our engineers reviewed the existing gasket design and application conditions and recommended an increase in height of 0.40 mm.

This was to increase the compression and improve the sealing function. Additional beads were also added to further stabilise the gasket in the groove.

The challenges

We manufactured prototype parts using a single-cavity soft tool and sent them to the customer for in-house testing and validation. The prototype gaskets nearly passed testing but fell just short of the 50 Bar pressure requirement at 150°C, achieving 42 Bar instead. Even so, they significantly improved on the performance of the customer’s original gasket.

Upon analysis of customer test data and furthermore by reviewing images of the tested parts, improvements were needed. We determined there were areas where the gasket was sliding in the groove and then shearing as the pressure pulsed. To resolve this issue, our engineers added beads to the rear of the T-intersections of the gasket. This provided additional support, further stabilising the gasket at the high-pressure stress points in the groove. This reduced the amount of movement within the housing.

Furthermore, the number of additional beads added needed to be balanced carefully with calculations on groove fill. Further development captured the cleanliness requirements and altered radii on the beads.

Customer satisfaction

With the new design approved, the customer moved to production tooling stage and sample parts were produced to PPAP Level 3. These parts have since been approved and full production quantities have been ordered manufacturing builds in 2022.

For more about our mouldings & gaskets, see our dedicated page HERE.