Precision Sealing for Naval Radar Slip Ring

The application

Our customer is a globally recognised leader in the design and manufacture of advanced slip ring systems and contactless rotary joints. Their technology ensures the reliable transmission of power, data, and media across a wide range of rotating interfaces. Read more about how our engineers developed a custom spring-energised seal for this application.

The application for this project is as demanding as they come. A naval radar system operating in some of the harshest conditions on the planet.

Mounted on a naval vessel, the slip ring assembly must operate continuously. Therefore it needs to function flawlessly, protecting electrical components whilst exposed to the elements (seawater, rain and wide temperature fluctuations).

The challenges

As well as these demanding conditions, the application itself also had several challenges. Furthermore, the design is a compact seal envelope, meaning design and installation need careful consideration.

A durable seal is needed – the expectation is that it can withstand over 6 million cycles across a 10-year service life. The seal required minimal breakout friction to avoid wear and conserve energy consumption.

This application required a rotary seal with low temperature capability and excellent resistance to oil-based fuels. The new design will replace the existing seal in the available housing between the rotating metal faces. We concluded a standard spring energised rotary seal would not work in the application, therefore we created a bespoke design.

Our sealing solution

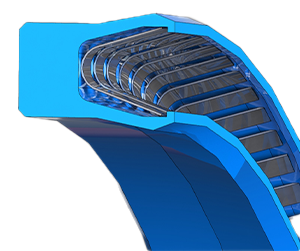

Our engineers developed a custom spring-energised seal, tailored precisely to the application’s needs.

We adapted the Parker Praedifa NLO profile and optimised it with a low-load spring for reduced friction, and a high-performance material formulation offering exceptional wear resistance.

Additionally, we included a design feature – heel slots allowing for dowel pin integration within the hardware to provide enhanced application stability.

Results

The final design delivered excellent sealing performance, passed all endurance tests, and met the full 10-year lifecycle requirement. Consequently, it maintained low friction throughout, ensuring energy efficiency and minimal wear. This is exactly what’s needed for a radar system where reliability is non-negotiable.

Learn more about our rotary seals HERE.