Seals for hydrogen applications

Hydrogen is the most common element in our universe, and is becoming an increasingly vital part in decarbonisation and a global sustainable energy future for our planet.

How is hydrogen produced?

Hydrogen offers a clean energy solution to parts of the economy that are difficult to decarbonise. These include industrial processes, domestic and industrial heating, and hard-to-electrify transport. This includes heavy-duty vehicles, ships and aircraft (where battery solutions are much less practical than they are for passenger cars). Hydrocarbons and water lock away most natural hydrogen, making it difficult to obtain.

Extracting hydrogen from either of these sources takes energy (and a lot of it!) but hydrogen becomes emission-free at the point of use. Today, 96% of the world’s hydrogen is produced using grey and brown processes. This means it’s not very environmentally friendly at all. It is widely accepted that we need to switch to, and expand green hydrogen production. However, the electricity sources for green hydrogen (solar, wind, etc) are not always located where the hydrogen needs to be used – and cannot be turned on and off as energy demand fluctuates.

The different colours of hydrogen

Generally categorised by a different colour, hydrogen is obtained by a variety of different methods. Grey hydrogen is produced by reforming natural gas (methane). Brown hydrogen is produced by converting carbon rich materials (such as coal) into hydrogen and carbon dioxide. These are common processes, but result in substantial carbon emissions.

Turquoise hydrogen is produced by the pyrolysis of methane at temperatures over 1000°C. Solid carbon is a by-product which is used or buried without emitting greenhouse gases or causing groundwater pollution. Blue hydrogen is generated by the steam methane reforming of natural gas. This generates large amounts of CO2 which must then be captured and safely stored. Pink hydrogen is created where large amounts of electricity is used to chemically split water into hydrogen and oxygen. Manufactured from a nuclear power plant, it’s free from ongoing emissions (other than those emissions produced in building the nuclear power station). The oxygen can be used by industry or vented to the atmosphere, without harming the environment.

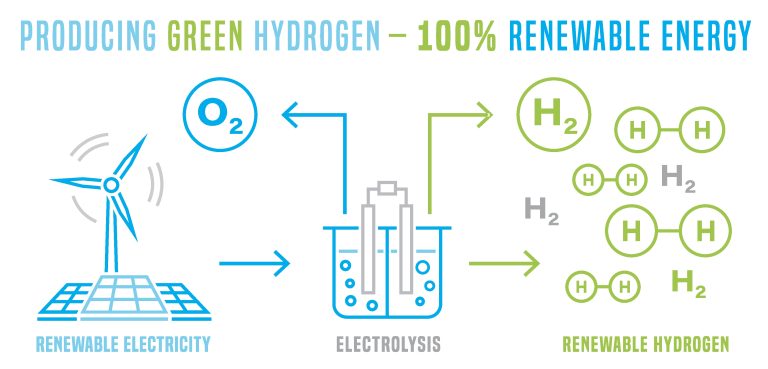

Green hydrogen is also produced by electrolysis of water, but the electricity required is taken purely from renewable sources such as solar, wind, tidal and geothermal processes. Experts widely regard this process as the only truly clean method of hydrogen extraction.

Engineered seals for hydrogen applications

Sealing hydrogen presents several challenges and we need to consider the following parameters when designing a sealing solution.

When it’s a gas, we need to consider the gas permeability of the sealing materials with pressures of 700 bar or more. The tightness of the static or dynamic sealing surfaces – including surface finish requirements for the mating components, also needs consideration. As a compressed and cooled gas, pressures can be up to 1000 bar in conjunction with temperatures down to -240°C. When it’s a liquid, the sealing solution needs to be suitable for the associated cryogenic temperatures of -253°C. However, pressure regimes are generally less than 5 bar in these conditions.

When hydrogen is within a carrier, the chemical compatibility requirements of the carrier medium must match the sealing materials specified. Carries include ammonia or liquid organic hydrogen.

Electrical conductivity or resistivity requirements, together with cleanliness and purity, may be required for sealing materials used in electrolysers and fuel cells.

Chemical and temperature compatibility with all the media associated with hydrogen production, transport and conversion processes, including all by-products, emissions, cooling fluids and electrolyte materials.

Seal applications in hydrogen

For seal applications in hydrogen with no particularly high demands in any one area, EPDM elastomer based solutions can often be the most cost effective. We offer chlorobutyl elastomer or polyurethane seals for permeation resistance. In high-pressure applications, engineers use elastomers or polyurethanes resistant to extrusion and rapid gas decompression, or PTFE unaffected by RGD.

In electrolysers and fuel cells, the purity and cleanliness requirements can be met with materials and treatments we frequently use within the semiconductor market. For applications below -60°C, elastomers become hard and brittle, but PTFE, PCTFE and metal sealing solutions can be used down to cryogenic temperatures. For high temperature applications, some FKM or even FFKM elastomers are used up to 220°C or even 300°C. However, the normal preference here is PTFE sealing solutions.

Metal seals are capable of even higher temperatures up to around 870°C. Metal seals can also have soft coatings such as tin or indium to achieve gas tight sealing, or gold or silver to reduce the risk of hydrogen embrittlement.

The evolving hydrogen industry

The hydrogen industry is technically vast and challenging for sealing applications, covering both extremes of temperature, alongside demanding pressure and chemical resistance requirements, coupled with stringent leakage limits and associated safety requirements.

Applications typically demand long service life and in certain cases require parts with high levels of technical cleanliness and purity.

Full consideration for the application is imperative. Elastomer, polyurethane, PTFE and metal sealing solutions are all options – providing the design and environment work harmoniously together.

Learn more about how we serve customers in the Hydrogen & Renewable Energy Industry HERE