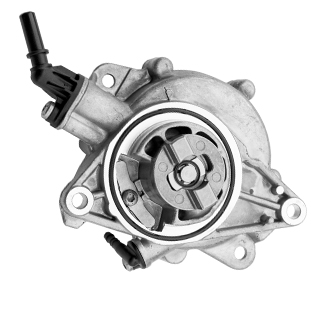

Special O-rings for an automotive application

Our customer manufactures high performance oil and vacuum pump solutions. They approached our engineers with a new O-ring for their automotive application.

The application

Our customer required an FKM (Viton™) 60 shore O-ring to meet Porsche material specification PN707 Class 2 (Oil), Class 5 (Fuel/FAME mix) and Class 12 (Blowby gas).

This was a very cost sensitive project and the lead time required was very tight; especially as we did not have an existing grade in our materials portfolio to meet this specification.

The challenges

Our engineers reviewed the application, and we provided two material options. The first was a lower cost grade of FKM (Viton™) A grade. This possibly meets the Porsche specification required. The second material to be offered was a medium to higher cost FKM (Viton™) B grade. This solution determined the best fit for the specification.

We supplied a quotation for both material options. These included production tooling, PPAP Level 3 submission (with samples), testing programme for both material variants and a pre-production batch of O-rings. This was an urgent project. Consequently, we could accommodate PPAP Level 3 grade O-rings for both materials to be manufactured from the same tool. Additionally, to save time we would conduct material testing in tandem with the manufacture and preparation of the production tool. The results of material testing will assist in the choice of compound used in the tool.

On completion of the material testing, the customer reviewed the results with Porsche. As a result, the decision to produce O-rings from the FKM B grade was made.

Customer satisfaction

By this stage of testing, production tooling was complete, allowing manufacture of PPAP 3 samples and the pre-production batch to commence. Pre-production O-rings were supplied to the customer in the promised 12-week lead time together with PPAP Level 3 and PPAP 3 samples.

See this link for more on our O-ring range and expertise: HERE