What is PEEK?

PEEK (PolyEther Ether Ketone) is a semicrystalline thermoplastic and except for piston ring sealing, is too rigid to work effectively as a tight sealing material, even with an energizing element. It has excellent strength, fatigue resistance and stability in high temperature environments, with a melting point around 343°C (662°F), and very good chemical resistance. It is a considered a high-performance polymer and this is reflected in the high cost of the raw material.

Why use PEEK?

With high levels of extrusion resistance, especially at high temperatures, PEEK is an ideal material to use for backing ring and seal support components in very high pressure applications or where large seal extrusion gaps cannot be avoided. Compared to even highly filled PTFE, it retains its strength properties until relatively close to the melting point, rather than gradually softening as the temperature increases. With the addition of fillers, high levels of strength can be achieved in combination with improved friction properties for applications where the PEEK component is forced into contact with moving hardware. It is a relatively expensive material and does not lend itself well to high volume manufacturing processes.

When to use PEEK

Frequently used as backing rings in applications with high temperature and pressure demands and therefore common in the oil and gas, CPI and some hydraulics industries. The material rigidity of PEEK requires use in open groove hardware, or for the backup component to be cut, and it often forms part of a staged or stacked backing ring solution alongside virgin or filled PTFE parts. To suit the application, fibre filled grades can provide higher tensile and compressive strength, whilst carbon, graphite or PTFE additives can be used to improve the wear and friction properties. Generally very inert, it can be attacked by halogens and aliphatic hydrocarbons. The continuous recommended operating temperature is -54°C (-65°F) up to +260°C (500°F) with some filled grades remaining sufficiently robust at up to +315°C (600°F).

Standard PEEK materials

This is a small selection of our general purpose PEEK materials. Many more compounds are available and can be chosen to suit the specifics of the application.

The tensile strength and elongation are for specification purposes. Typical achieved values can be significantly higher.

Temperature range is general recommendation for static application in air. Temperature ratings are subject to full application review.

(Shore)

MPa min

% min

temperature range

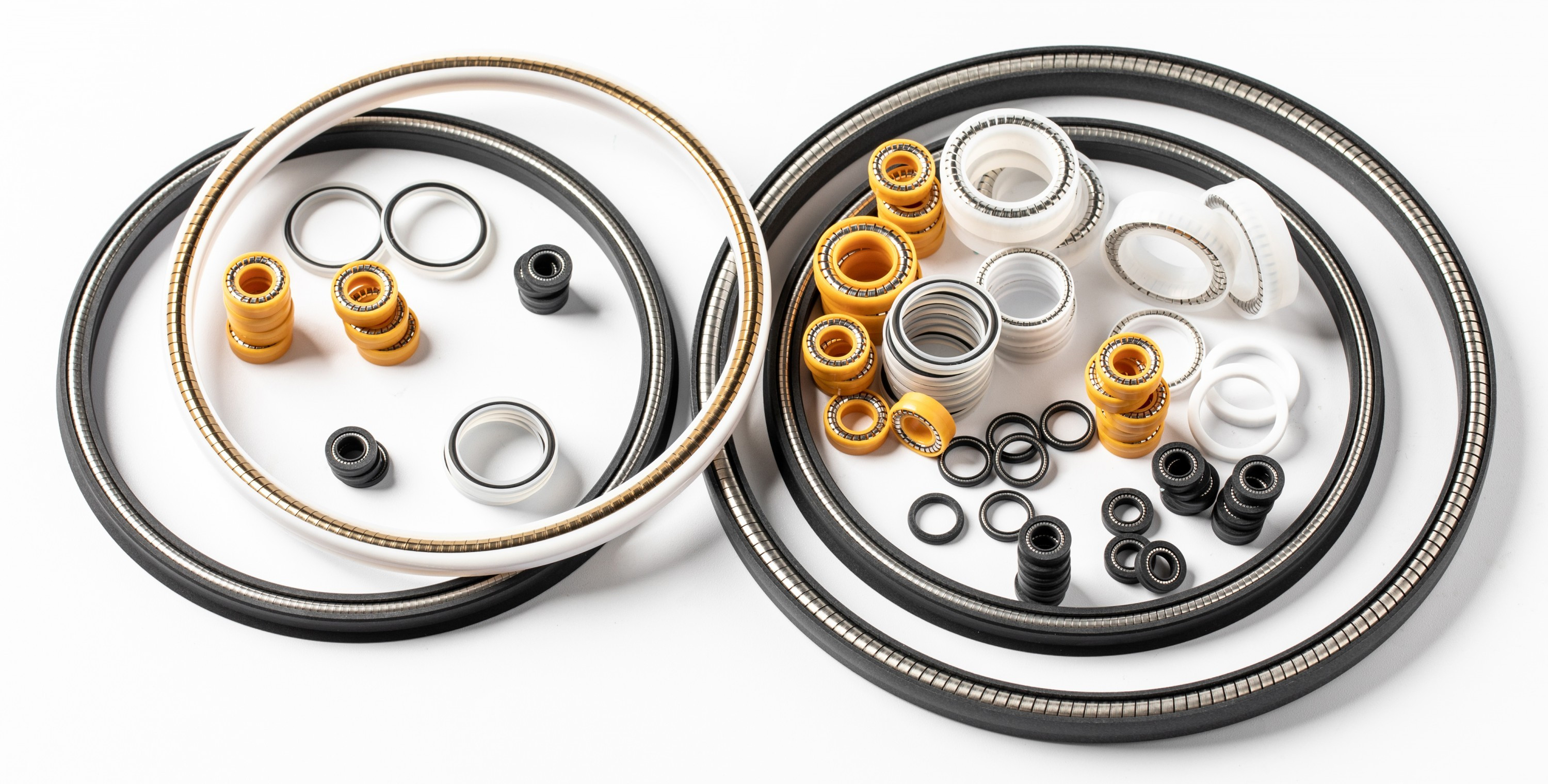

Our Products

We have a range of key products available in endless size and material combinations depending on your individual application requirements.