What is AU/EU?

AU (polyester urethane) and EU (polyether urethane) are the two types of polyurethane elastomer used in the manufacture of seals, comprising the U-Group with carbon, oxygen and nitrogen in the main chain. Polyurethane is synthetically produced by reacting an isocyanate with a polyol in the presence of a catalyst and can be used for products as diverse as foam mattresses to car dashboards to varnish. By carefully selecting the isocyanate and polyols, the properties of the final material compound can be aligned with the requirements for sealing products; such materials have excellent wear and extrusion resistance, high tensile strength and high elasticity in comparison with all other elastomers.

Why use AU/EU?

The material has superb abrasion resistance and toughness whilst it can be both injection moulded to produce seal profiles in high volumes and also produced as tubes from which seals can be machined in lower volumes. This combination of properties and processing options makes it a very competitive material against other elastomers in terms of performance in dynamic applications, and also attractive compared with PTFE based sealing solutions in terms of cost effectiveness. They can be sensitive to humidity and hot water, suffering hydrolysis, unless specifically formulated to resist this chemical attack and their use is limited to an extent by the temperature range they can tolerate.

When to use AU/EU

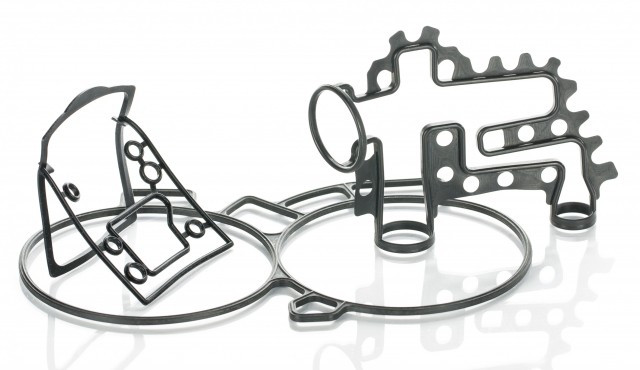

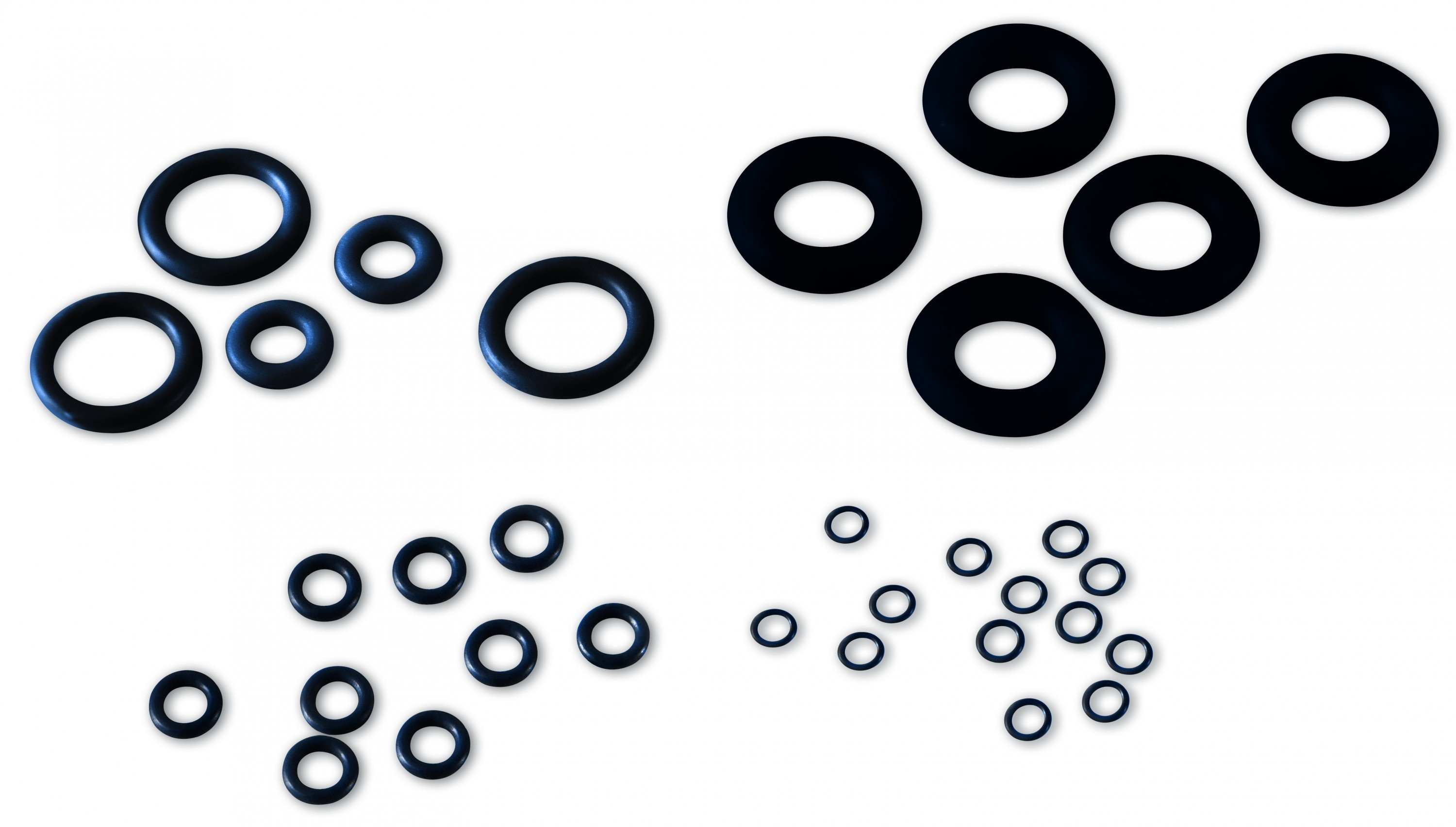

Commonly found in dynamic sealing applications in hydraulic and pneumatic systems where the temperatures, pressures and operating speeds are not excessively demanding. PU is highly resistant to gas permeation, ozone and weathering, and chemically compatible with many hydraulic fluids, petroleum oils and hydrocarbon fuels, but exposure to acids, ketones and chlorinated hydrocarbons should be avoided. Polyurethane o-rings exhibit high extrusion resistance and can often be used as a one-piece solution in place of a softer elastomer and backing ring combination. General grades can work between -54°C (-65°F) and +93°C (+200°F ) with special grades extending this to +135°C (275°F).

Standard AU/EU materials

This is a small selection of our general purpose AU/EU materials. Many more compounds are available and can be chosen to suit the specifics of the application.

The tensile strength and elongation are for specification purposes. Typical achieved values can be significantly higher.

Temperature range is general recommendation for static application in air. Temperature ratings are subject to full application review.

(Shore)

MPa min

% min

temperature range

Rubber Shelf Life

Guidelines for storage and shelf life of rubber products.

Our Products

We have a range of key products available in endless size and material combinations depending on your individual application requirements.