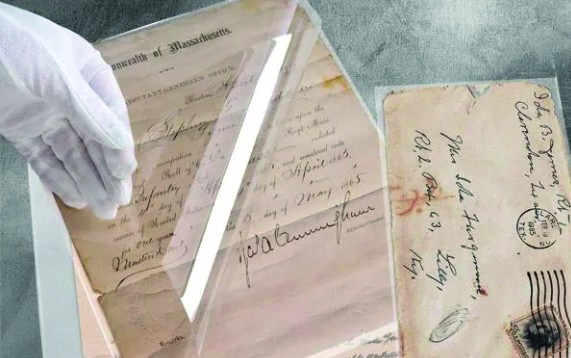

Our team of engineers worked with Preservation Equipment Ltd (PEL) who supply materials and equipment for professionals working in the field of conservation and preservation of archives, works of art and ancient artefacts.

What was the application?

We have previously supplied a machine that manufactured polyester pockets for document storage.

The customer required a further machine for sealing the open edge of the premade pocket after the insertion of a document; offering total protection before storage.

A basic heat sealing device was required and needed to be a relatively low cost and efficient solution. It needed to be simple to use, with minimum maintenance requirements, and a constant quality of seal to be produced at every cycle.

It needed to be suitable for heat sealing two different gauge thicknesses of polyester.

Our Heat Sealing solution

Our engineers designed a a brand new machine for this application; the Bench Top Heat (BTH) sealer).

This was a basic and economic heat sealing machine with simple, manual operation. It has timer controlled heat sealing, which differs from our other heat sealing technologies, as it has no temperature feedback and subsequent adjustable control.

To create the required heat seal, the operator pulls the lever to clamp the material and then presses a foot switch. When completion of the sealing cycle is indicated, the operator simply releases the clamp, and removes the finished product.

This bespoke built machine provided our customer with accurate and suitably reliable heat sealing

If you require support on heat sealing solutions complete our application form here.