Market features

ISO9001:2015, ISO 14001:2015 approved and manufacturing IATF16949:2016 approved

Vast product range suitable for all application conditions

Broad material range fully compliant with FDA, USP Class VI, ISO 10993, UHP, BAM and BfR standards

ISO9001:2015, ISO 14001:2015 approved and manufacturing IATF16949:2016 approved

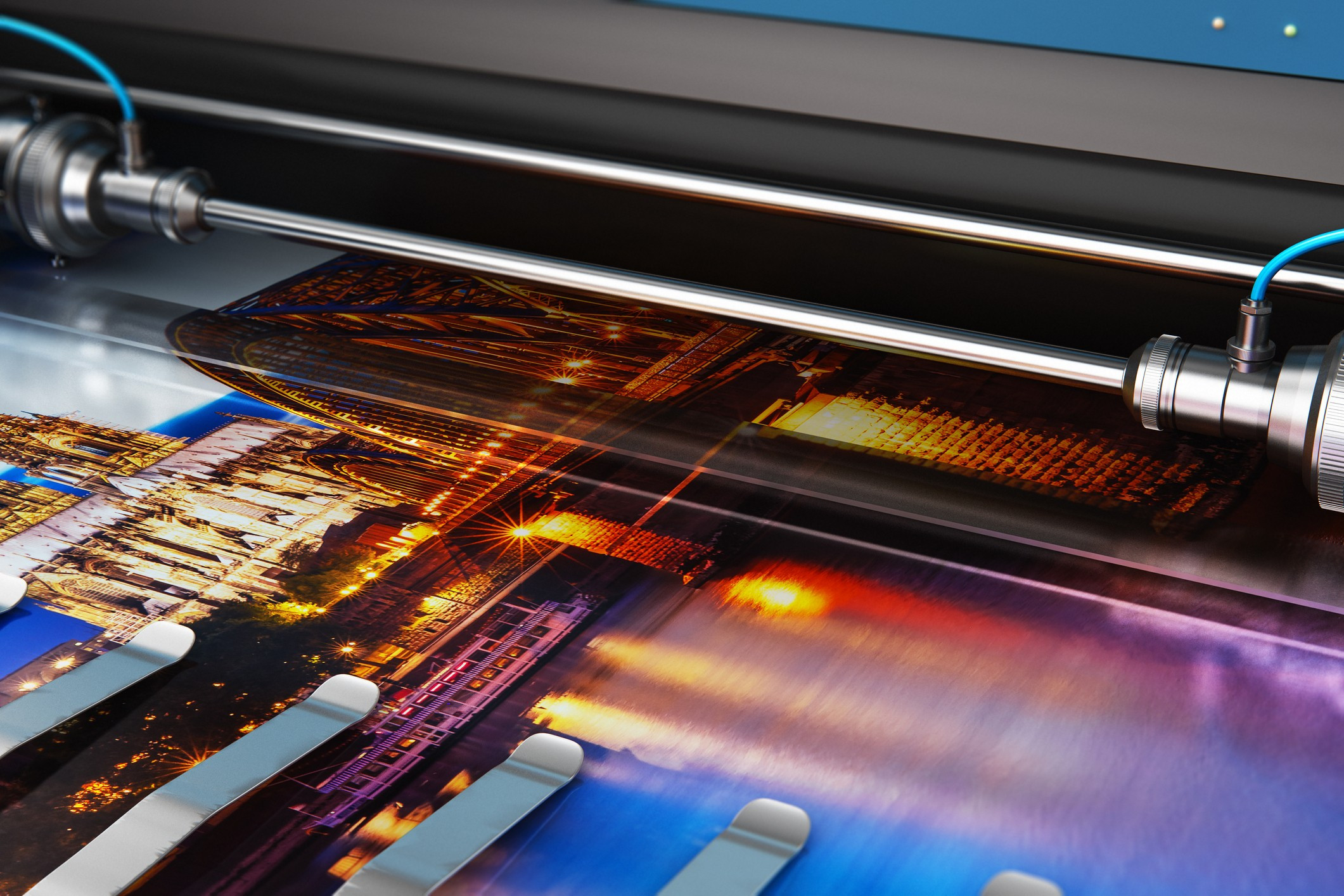

Seals for Process and Printing equipment

We offer a variety of seals suitable for equipment used in the printing, food process and chemical process industries.

Specifying seals for equipment used for food and beverage production presents a number of challenges for our application engineers during the design and selection process. The seals must be compatible with the ingredients of the food they come into contact with, and these can include acids, sugars and salts which are often abrasive in nature.

As hygiene and compliance are of the utmost importance seals must meet strict high purity standards such as FDA or BfR (which stipulate acceptable ingredients are neither toxic nor carcinogenic). Other approvals such as 3-A and E-3A and NSF51 can be requested depending on individual customer requirements.

The seals must also be suitable for use with any cleaning fluids that may be used in CIP (Clean In Place), SIP (Steam In Place) or general wash down procedures, and process and cleaning temperatures also affect the type of seal and material selected.

Specifying seals for the print industry requires careful selection of elastomers that are stable from the risks of swell and extraction caused by aggressive ink constituents such as MEK (methyl ethyl ketone).

We have a range of special grades of elastomers such as EPDM's, FFKM's to ensure reliable sealing function within the customer mating parts, thus meeting the demands of reliable sealing in new ink variants. In addition, the challenges of reduced packaging space requires the need of complex seal profile designs which also need to be manufactured to tighter tolerances.

Coloured compounds are available for ease of identification.

Our extensive range of Process industry seals includes:

· O-rings

· Special mouldings and gaskets

· Lipseals

· Composite seals (chemical bond or over-moulding)

Our Brochures

Our Products

We have a wide range of products and materials suitable for applications in all industries.