Rotary seals for heavy duty transportationSupply Plus Ltd designs, manufactures, supplies and distributes safety and fuel delivery equipment, with brands including AS Fire & Safety, Bayley and Collins Youldon. They approached us to design a rotary seal to replace their existing solution which was causing leakage during downtime. The application Supply Plus initially approached us with a requirement for their 2” Swing joint power spindle.In this application, the outlet pipe from the fuel tank on delivery vehicles feeds into the centre of a rotating hose reel (located between the tank and cab of the vehicle). An electric motor powers the reel and pumps the fuel through at relatively low pressure.The customer’s main issue with the existing design was leakage. This is from the hose fitting in low temperatures especially at -25°C during winter, and when vehicles were parked over-night. The challenges The application required a rotary seal with low temperature capability and excellent resistance to oil-based fuels. A design was required to replace the existing seal in the available housing between the rotating metal faces. We established that a standard spring energised rotary seal would not work in the application; a bespoke design was required.The leakage at night when vehicles were not in use suggested the issue was worsened when the seal was both cold and not energised. Therefore, we designed a rotary seal that would remain energised at low temperatures and low pressure. Our sealing solution Our engineers designed a simple but effective seal. It incorporated a large heel in the base of the housing that energised a lip sealing on a rotating metal face. The volume of rubber in the heel of the seal, combined with the 170° angled base created sufficient force to maintain a seal at low pressure.We specified a low temperature Viton to ensure the seal retained elastomeric properties. It also applied the sealing force at low energising pressures and very low temperatures. This combination provides excellent resistance to fuel oils, diesel and aviation fuel. Prototypes were tested at both an in-house test unit and in the field for a period of four winter months. Results showed no issues during dispense of fuel and a complete cessation of leakage. The seal was approved and production orders placed, and now the design has been incorporated across additional sizes of hose reels.

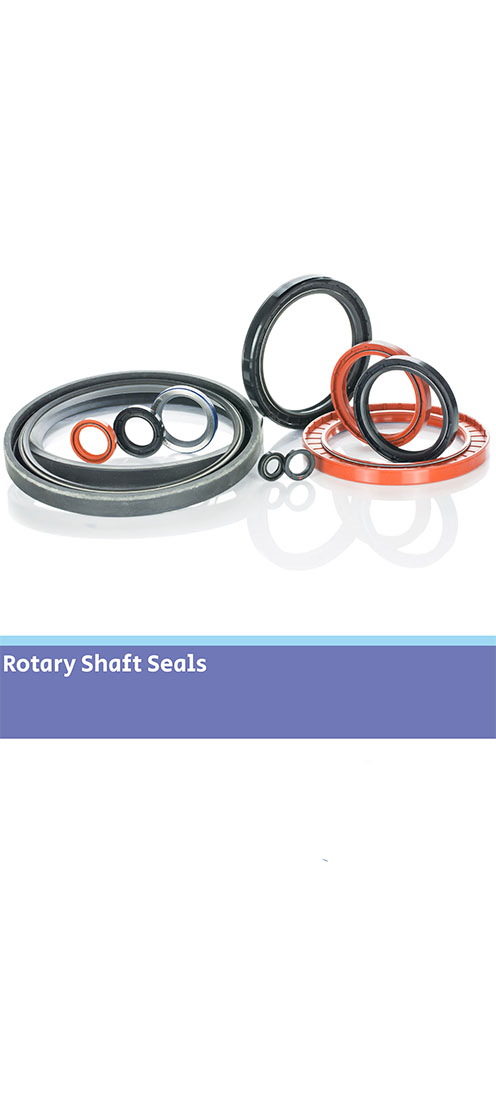

Rotary seals for heavy duty transportation

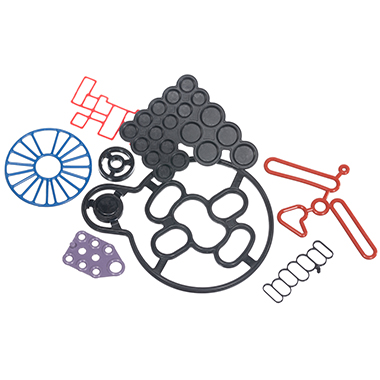

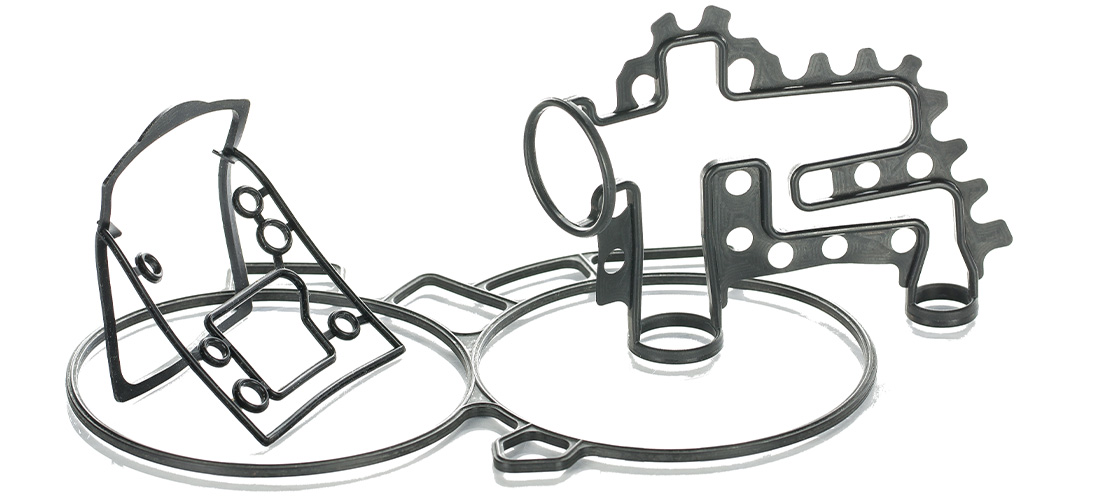

Moulded gaskets for an automotive applicationMoulded gaskets for an automotive application An existing customer (an automotive manufacturer) approached our engineers with an application where they were experiencing failures of a seal designed and manufactured by another rubber seal provider. Here we explore more about our solution for a moulded gasket for this automotive application. The application This gasket is used within a valve housing in an automotive application. The original competitor gasket was experiencing failure at the "T-junction" areas of the seal. Therefore, our customer had experienced chronic failures of their existing design at high temperatures and high pressures.A pulsating pressure of up to 50 Bar and temperatures up to 150°C provide an extreme environment for the seal. Consequently, our engineers reviewed the existing gasket design and application conditions and recommended an increase in height of 0.40 mm.This was to increase the compression and improve the sealing function. Additional beads were also added to further stabilise the gasket in the groove. The challenges We manufactured prototype parts using a single-cavity soft tool and sent them to the customer for in-house testing and validation. The prototype gaskets nearly passed testing but fell just short of the 50 Bar pressure requirement at 150°C, achieving 42 Bar instead. Even so, they significantly improved on the performance of the customer’s original gasket.Upon analysis of customer test data and furthermore by reviewing images of the tested parts, improvements were needed. We determined there were areas where the gasket was sliding in the groove and then shearing as the pressure pulsed. To resolve this issue, our engineers added beads to the rear of the T-intersections of the gasket. This provided additional support, further stabilising the gasket at the high-pressure stress points in the groove. This reduced the amount of movement within the housing.Furthermore, the number of additional beads added needed to be balanced carefully with calculations on groove fill. Further development captured the cleanliness requirements and altered radii on the beads. Customer satisfaction With the new design approved, the customer moved to production tooling stage and sample parts were produced to PPAP Level 3. These parts have since been approved and full production quantities have been ordered manufacturing builds in 2022.For more about our mouldings & gaskets, see our dedicated page HERE.

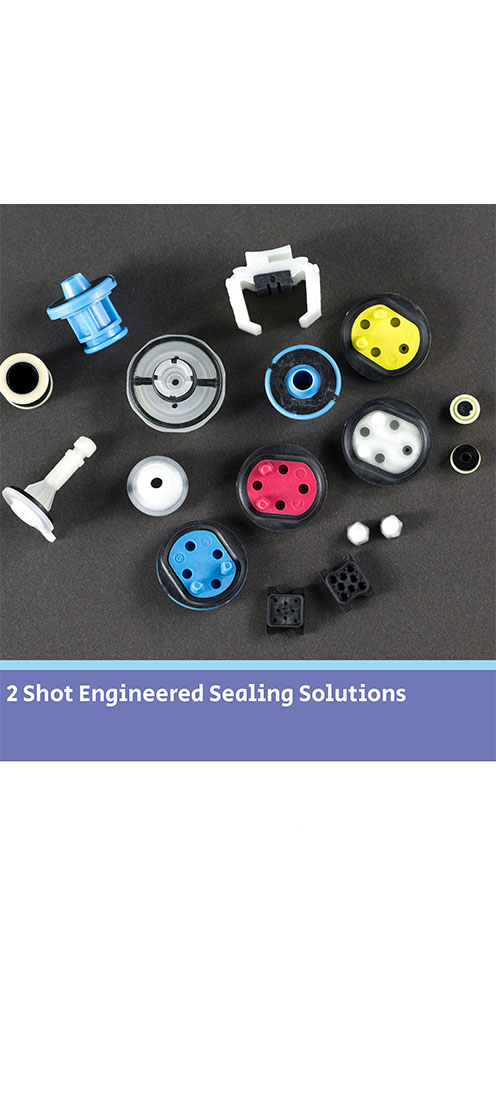

Moulded gaskets for an automotive application

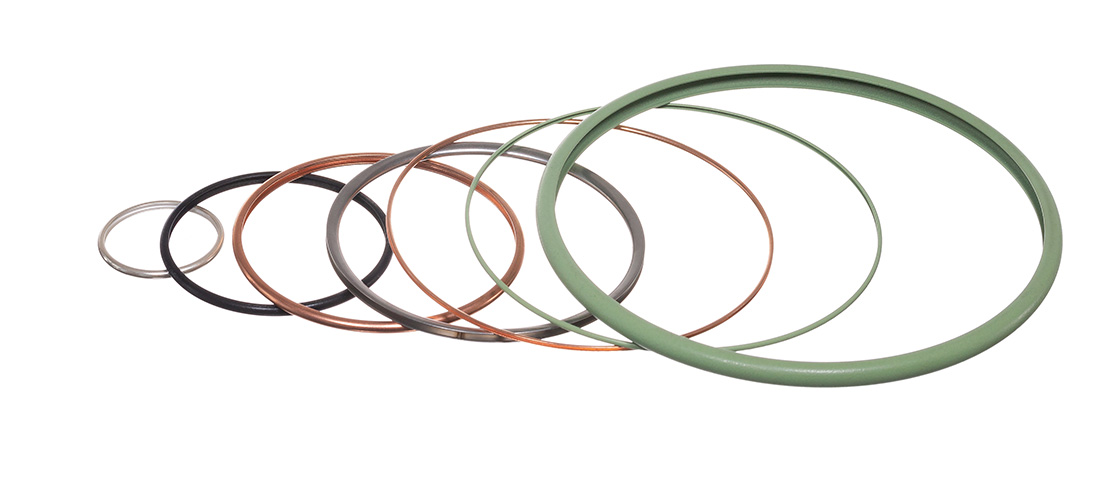

Special O-rings for an automotive applicationSpecial O-rings for an automotive application Our customer manufactures high performance oil and vacuum pump solutions. They approached our engineers with a new O-ring for their automotive application. The application Our customer required an FKM (Viton™) 60 shore O-ring to meet Porsche material specification PN707 Class 2 (Oil), Class 5 (Fuel/FAME mix) and Class 12 (Blowby gas).This was a very cost sensitive project and the lead time required was very tight; especially as we did not have an existing grade in our materials portfolio to meet this specification. The challenges Our engineers reviewed the application, and we provided two material options. The first was a lower cost grade of FKM (Viton™) A grade. This possibly meets the Porsche specification required. The second material to be offered was a medium to higher cost FKM (Viton™) B grade. This solution determined the best fit for the specification.We supplied a quotation for both material options. These included production tooling, PPAP Level 3 submission (with samples), testing programme for both material variants and a pre-production batch of O-rings. This was an urgent project. Consequently, we could accommodate PPAP Level 3 grade O-rings for both materials to be manufactured from the same tool. Additionally, to save time we would conduct material testing in tandem with the manufacture and preparation of the production tool. The results of material testing will assist in the choice of compound used in the tool. On completion of the material testing, the customer reviewed the results with Porsche. As a result, the decision to produce O-rings from the FKM B grade was made. Customer satisfaction By this stage of testing, production tooling was complete, allowing manufacture of PPAP 3 samples and the pre-production batch to commence. Pre-production O-rings were supplied to the customer in the promised 12-week lead time together with PPAP Level 3 and PPAP 3 samples.See this link for more on our O-ring range and expertise: HERE

Special O-rings for an automotive application

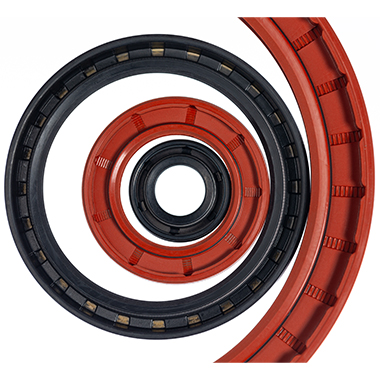

High speed Rotary seals for electric vehiclesHigh speed Rotary seals for electric vehicles The electric vehicle industry is growing; global manufacturing and registrations of electric vehicles is increasing exponentially each year. Our engineers have extensive experience in designing seals for automotive applications, but we still find new challenges involved in sealing components within hybrid, hydrogen fuel and full battery powered electric vehicles. The application Our customer has over 30 years’ experience of providing pioneering technologies globally to the mobility industry. This established company is a supplier of powertrain solutions for electric and hybrid vehicles, additionally traditional internal combustion power engines.Their team of powertrain development experts approached our engineers for a rotary shaft sealing solution for the gearbox within an electric vehicle. The position of the seal was required between the wet transmission and dry e-motor, and pressed into a bulkhead housing.The sealing lip runs on the surface of the transmission rotor shaft and pressed radially by a tension spring onto the shaft. Additionally, it required a dust lip to provide protection against environmental dirt and debris on the dry motor side.The shaft and housing dimensions were all fixed by the customer. However, they provided a full dimensional, surface finish, pressure, temperature and media specification. This enabled our engineers to review and propose a bespoke seal design Our sealing solution The application media was a synthetic oil. This is relatively standard for an automotive application. However, because of the maximum working temperature, FKM (Viton) was the elastomer material to meet the required range.As with many applications within electric vehicle gearboxes, the shaft speed was particularly high at 8500 RPM. Typically, with these high speeds, seal design needs to ensure minimal friction to ensure the service life required.Our application engineers designed a bespoke, double lipped spring energised seal.On the dry e-motor side, the rubber lip was designed to act as a dirt and dust excluder, with slight clearance from the shaft to avoid friction. This prevents damage to the seal and unnecessary wear to the rotary system as a whole.In the wet transmission side, it was imperative that the oil was kept away from the e-motor with the same minimal friction requirements. As a result, our engineers have designed the seal with an inlaid PTFE lip with 15% graphite fill. It was energised with spring to ensure force which achieves ultimate shaft sealing performance.Read more about our rotary seals HERE

High speed Rotary seals for electric vehicles

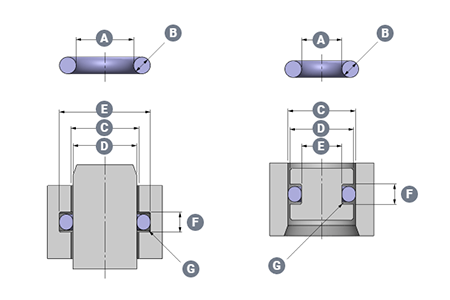

Why use PTFE seals?Why use PTFE seals? Polytetrafluoroethylene (PTFE) is a thermoplastic polymer. PTFE seals can be used in a variety of sealing applications. It’s suitable when application conditions exceed parameters of elastomeric seal use but not to the extent of a metal seal. What is PTFE? It has a high melting point (342 °C) and morphological characteristics. These allow seal components made from virgin PTFE to be used continuously at service temperatures of up to 260 °C. With the addition of fillers – up to 300°C. It has the unique ability to resist material degradation, heat-aging and alteration in its physical properties during temperature cycling. Alongside this rare combination of material characteristics, PTFE also has unlimited shelf life. Why use PTFE seals? Notably PTFE demonstrates extraordinary chemical resistance. The intrapolymer chain bond strengths preclude reactions with most chemicals, thereby making it chemically inert at elevated temperatures and pressures with virtually all industrial chemicals and solvents. Only a few media (some molten alkalis) are known to react with PTFE seals making them the perfect sealing solution for highly aggressive chemical applications.PTFE also has the lowest friction coefficient of any known solid. It has self-lubricating capabilities which offers continuous dry running ability in dynamic sealing applications and has superb stick/slip capabilities. Focus on dry coatings The advantages of using PTFE in sealing applications are multiple:Functionality at high and low temperaturesDynamic sealing with high wear capabilitiesHigh pressure sealing (using combinations of PEEK back-up rings)Compatibility with highly aggressive chemical combinations.Our range of PTFE seal products include back-up rings, rod and piston seals, slipper seals and spring energised seals in a wide variety of sizes. Materials depend on application requirements. However, we offer a wide range from Virgin PTFE or including filler combinations of MoS2, glass, carbon, carbon fibre, graphite, and bronze.These characteristics make PTFE seals perfect for the demanding applications involved in Oil & Gas, Aerospace, Automotive and Chemical Process markets (to name but a few). Ceetak’s engineering team are experienced in the design of PTFE sealing solutions to meet the complex specifications these types of application demand.Read our overview and more detail about PTFE seals HERE

Why use PTFE seals?

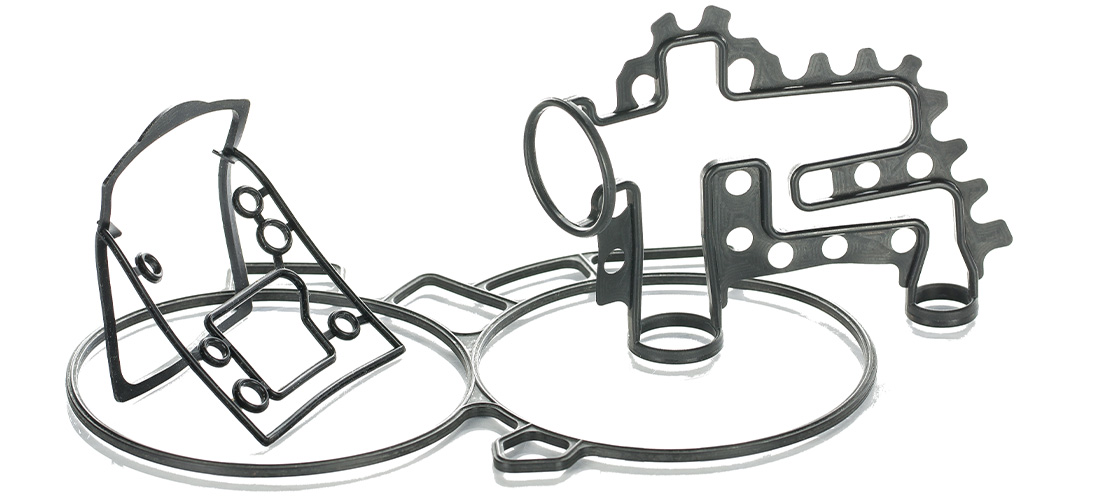

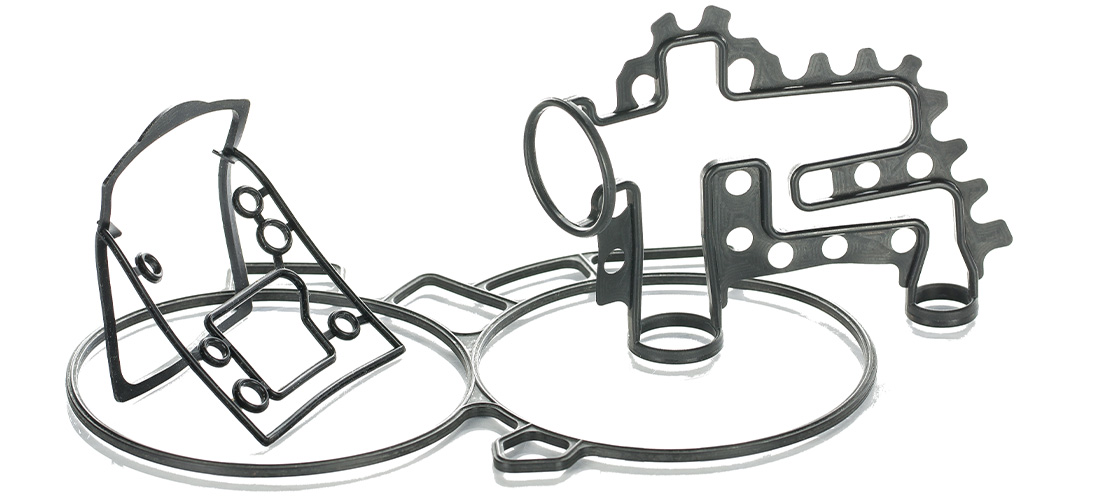

Why use Push-in-Place gaskets?Why use Push-in-Place gaskets? Where a seal groove follows an irregular path or profile, a common sealing solution is to design a custom Push-In-Place (PIP) gasket. This will have the same profile as the centre line of the groove, and simply drops into place, retained by the features of its own design. Gasket sealing overview There are many ways to seal the static join between two components. This could be to keep fluids inside a cavity, or to keep fluids or contaminants out of a device or assembly. The options will vary from simple O-rings, moulded elastomer gaskets and flat sheet style materials, to liquid gaskets (or RTV’s).As with all sealing applications, the optimal sealing solution is designed by first reviewing the application conditions. These include temperature, pressure, fluid exposure etc. Other variables such as life requirement, equipment serviceability and seal compression set will all be considered. Arguably though, compared to other sealing applications there are considerations when designing face, cover or flange sealing solutions. It is imperative to consider the packaging requirements and assembly issues of gasket sealing options. For example, if there is a need to avoid or seal around bolt holes (or other retaining/clamping devices). Additionally, consideration around optimizing hardware wall sections or depths can play an important part in choosing the most suitable gasket sealing technique. What are Push-in-Place gaskets? With the right combination of application conditions, an O-ring style approach to sealing may be the most appropriate. O-rings tend to require relatively shallow grooves compared to their cross section in one half of the assembly. In cases where the groove is round in plan view – they can be a good solution.However, in cases where the groove follows a more irregular path or profile (frequently referred to as a “racetrack”) the O-ring can sometimes pop out in places. This will be often where the two housing parts are being brought together. A common solution is designing a custom moulding with the same profile as the centre line of the racetrack groove. This will simply drop into place.A similar approach is used when the application or hardware constraints steer the design towards a gasket that has a greater cross section depth compared to the width. This would typically be designed so the centre line of the gasket matches the centre line of the groove plan profile – again so that it drops easily into place.An inherent problem with gaskets that can drop into place is that often, they easily drop out of place too. This can occur when the component needs to be inverted or has the potential for rough handling during assembly. Consequently, the gasket may become partially or fully dislodged from the groove, which results in a badly sealed interface. The best solution to this issue is to incorporate retention pips or bumps in the gasket design. This is a solution known as Push-In-Place (PIP) gaskets. These require a distinct force to put them into the groove. Subsequently, they require more than just gravity to get them out of the groove. Why use Push-in-Place gaskets? There are other less effective solutions for tricky groove sealing, such as the use of a sticky grease, or the use of an adhesive. These can bring compatibility and health and safety issues to consider. Additionally, the risk that any contaminant could keep the gasket off the surface that it’s supposed to be sealing against. As a result, the integrity of the seal can be severely compromised.Neither of these approaches can be recommended. Instead, the use of retention pips is a safe and secure way of ensuring the gasket remains in the groove. How do retention pips work on a gasket? To determine the optimum number, size and position of the retention bumps, Finite Element Analysis is used. This ensures they provide sufficient squeeze to prevent the gasket being easily dislodged. Additionally, it’s important the groove space isn’t overfilled with seal material or interfering with the seal compression footprint against the hardware faces.The bumps can be strategically positioned to control any distortion of the gasket under pressure or temperature conditions. For example, low temperature conditions can shrink the gasket and tighten the radius it adopts around a bend in the racetrack profile. This can reduce the seal compression locally and potentially create a leak path.By positioning retention bumps at either end of the bend, the thermal contraction will be controlled to minimize leakage risk.Effective retention is needed to ensure the gasket remains correctly located in the groove even with varied use. For example, if the part needs to be inverted (sometimes the preferred assembly method for practical reasons). Alternatively, it could be subject to rough handling.For large gaskets this is normally the most effective solution. On smaller gaskets (particularly those located well inside the periphery of the assembly), there is a significant risk of a dislodged gasket being totally undetected unless using a PIP gasket design. Monitoring gaskets - human eye or testing machinery It is possible to include tell-tale signs on a gasket design. For example, if a part of the elastomer gasket protrudes sideways through a gap in the housing wall the presence of the gasket can be checked. This will be either with the human eye or an automated vision system. However, this does not ensure correct seating all around the gasket length. Additionally, it cannot be used for internal gasket locations. In these cases a missing or badly fitted gasket would only be discovered during post-build testing, or even worse with a machine failure at a customer.If included at the design stage, the small additional tooling and material costs associated with a PIP gasket are negligible compared to the costs of an impossible assembly scenario, strip and re-build costs on the assembly line, or the consequential costs associated with failure of an assembly once delivered to a customer.More information on PIPs and gaskets can be found HERE

Why use Push-in-Place gaskets?

Seals for electric vehiclesSealing solutions for electric vehicles Propelled by one or more electric motors and using energy stored in rechargeable batteries, electric vehicles are quieter, have zero exhaust emissions and lower emissions in general compared to internal combustion engines. The number of electric vehicles on the road grows exponentially every year globally, and our engineers support manufacturers with innovative sealing solutions in these specialist areas of application. Hybrid vehicles Hybrid vehicles have a petrol (or diesel) engine combined with an electric motor and a relatively small battery. They feature all the traditional areas of automotive applications that require seals including oil, steering, suspension and braking systems.They also require seals for environmental and RFI/EMI (Radio Frequency Interference /Electro Magnetic Interference) applications. These are normally gaskets required for multiple electronic control, junction and connection boxes (for power invertors, charging electronics, motor and battery enclosures). These are generally placed around the vehicle; however, batteries are often under or behind the back seat. Sometimes the fuel tank is smaller, and the battery sits in a similar place.Application characteristics also include high speed rotary sealing requirements around the output shaft of the motor and potentially in the gearbox that links in with the combustion engine drivetrain. Plug-in hybrid vehicles have gaskets or seals (environmental and/or shielded) associated with the cable charging connection. Hydrogen fuel cell These vehicles have no combustion engine, and the fuel cell is often located where the petrol engine would be. Electrical power is produced by passing hydrogen and oxygen gasses through a “battery” (the cell). Anodes and cathodes in the cell produce electricity, driving the motors and is also stored in more conventional hybrid style.Waste product is water and warm air; this is very environmentally friendly. This is compared to pure battery power which uses electricity. This is often generated in a “non-green” way and which also consumes rare earth minerals such as lithium.There are traditional automotive seals in areas of applications such as steering, cooling, suspension, and braking systems. These are in addition to environmental and RFI/EMI shielding gaskets and high-speed rotary seals requirements. Hydrogen gas is normally stored in a tank at up to 700 bar pressure. Again, is usually situated just behind, or under the back seat, and requires sensors, valves and pressure regulators to operate.There are seals and gaskets required within the fuel cell itself, these require H2 resistance. Some fuel cells have small compressors which force the gasses through the fuel cell at higher pressure for improved efficiency. Then expanders which recover energy from this gas flow at the exhaust of the fuel cell. These often require high speed rotary seals (generally PTFE materials) and they run unlubricated. Battery applications Full battery electricThese vehicles have large batteries that typically take up the entire floor area underneath all of the seating compartment of a car. As with other EV’s there are the traditional seals in automotive areas; no oil system, but the steering and cooling systems, for the battery itself and the suspension and brakes. There are also environmental and EMI/RFI shielding gaskets and high speed rotary sealing requirements. The plug in charging ports also present a sealing application. Filling and chargingThere are many different applications for filling and charging. Home charging points are normally smaller and wall mounted for domestic use, while commercial and forecourt charging will encompass hydrogen filing. There are all similar application types as already mentioned including shielded and environmental gaskets for the electric applications and hydrogen sealing for the H2 filling applications. Design & Development for Electric Vehicle applications Our engineering team understand the demands associated with automotive applications, and we support vehicle manufacturers by designing innovative sealing solutions for electric vehicle applications.We use the latest in 2D/3D CAD and FEA simulation software to design and replicate automotive seal performance before finalising each individual seal design, incorporating significant feature and critical function elements for integration with customer mating parts. We offer material development and testing, and a component endurance testing service.Learn more about our expertise in the Automotive & EV industry HERE

Seals for electric vehicles

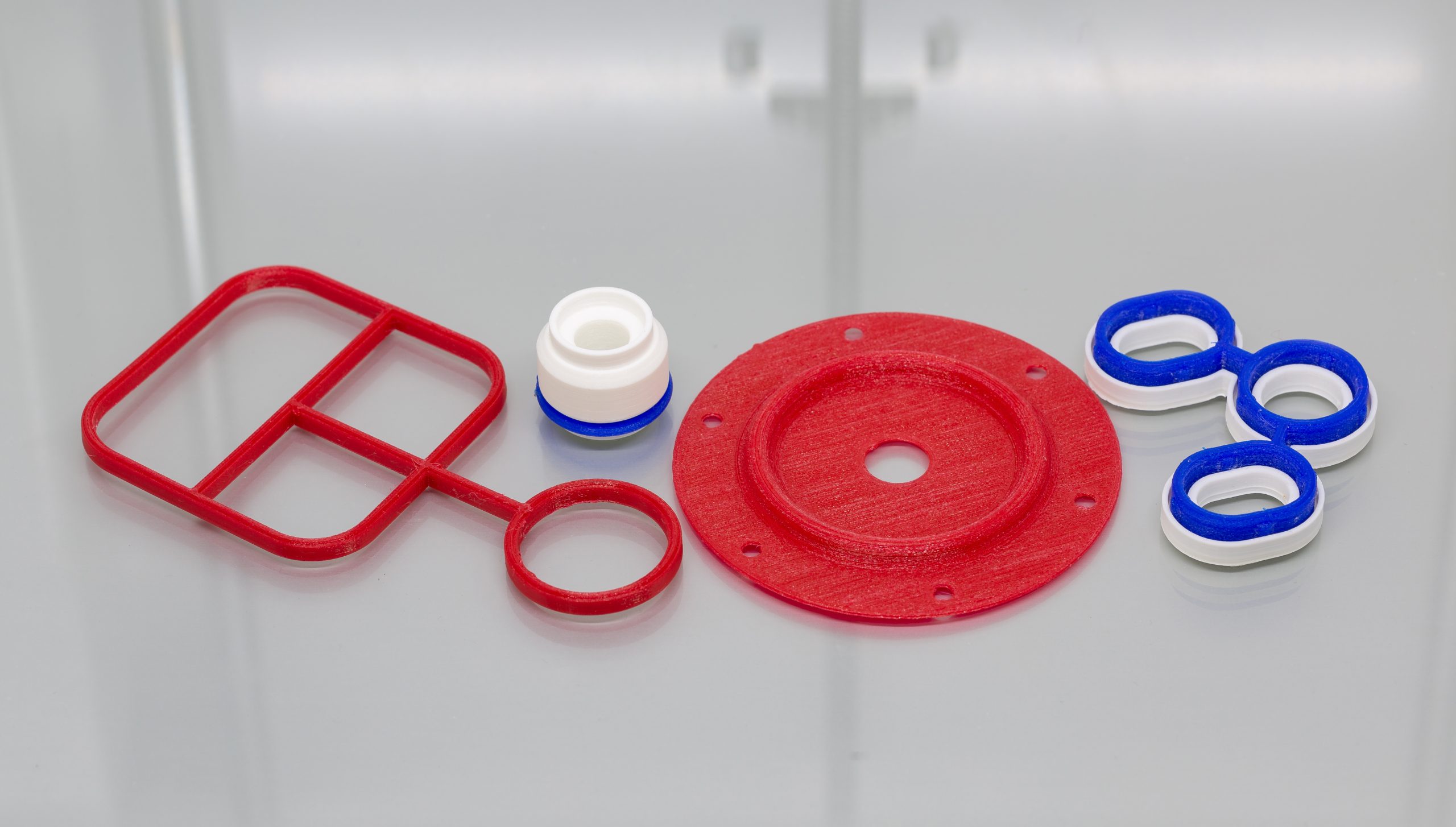

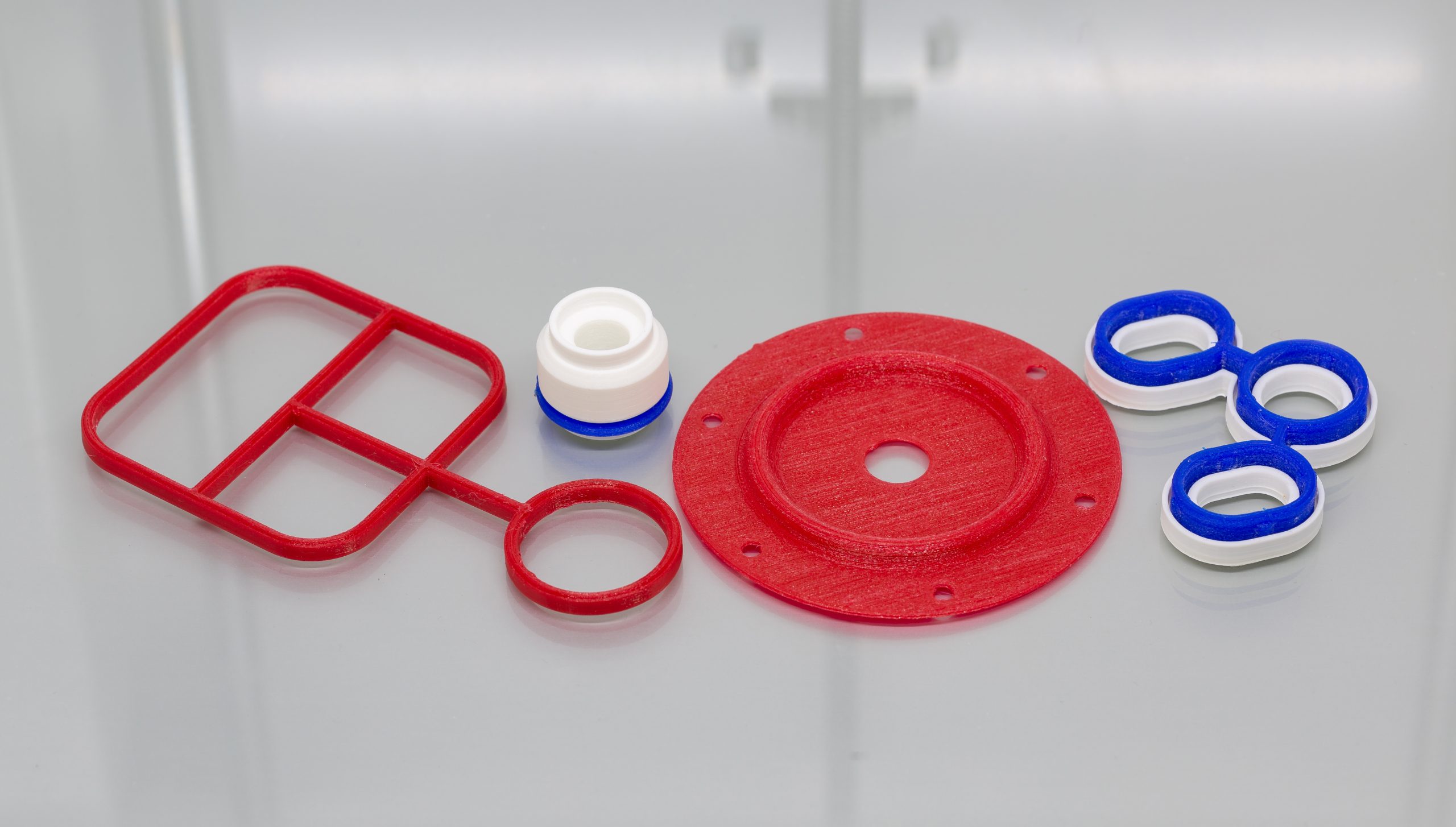

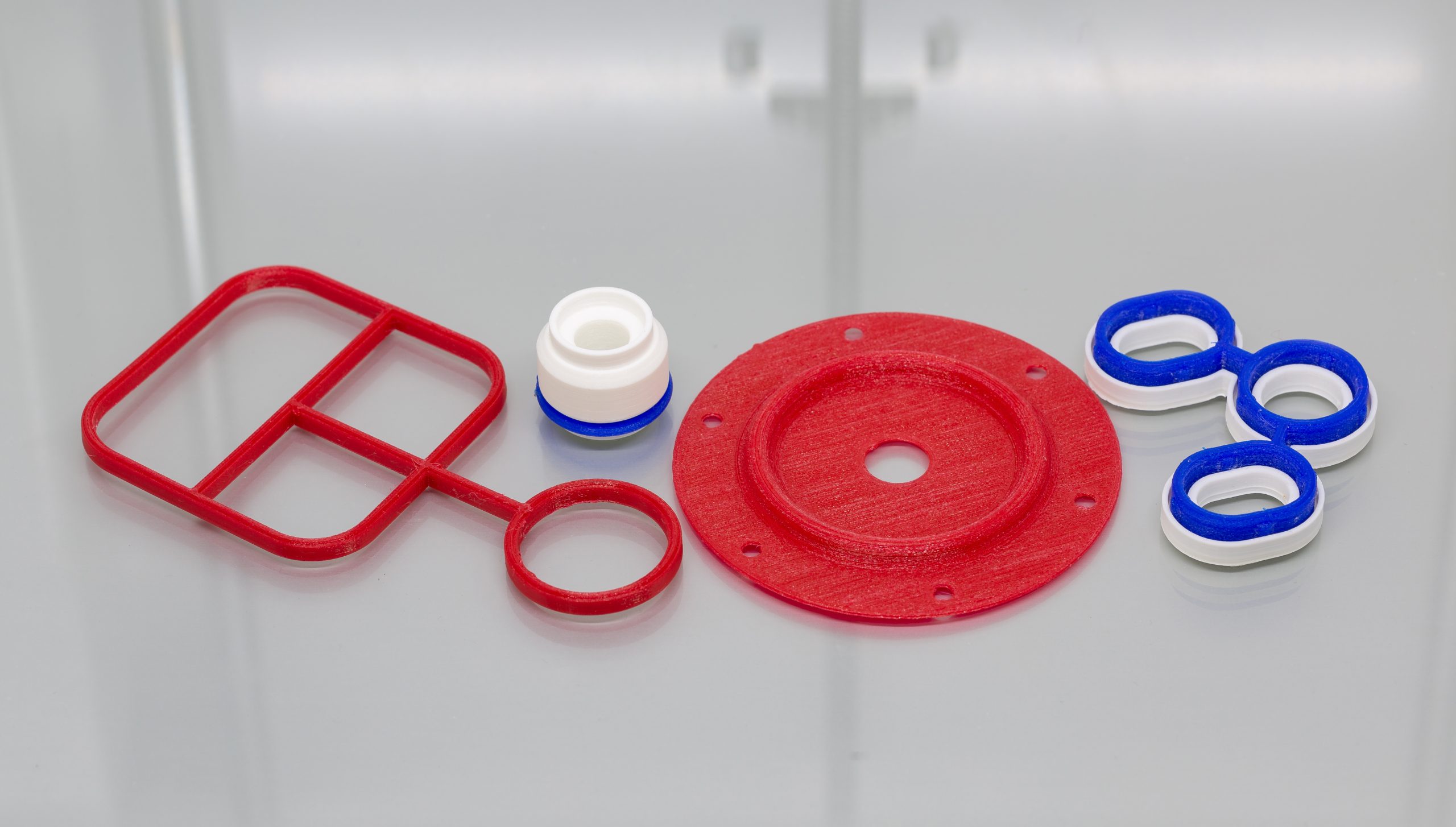

3D printing for seals3D printing for seals 3D printing has developed significantly and now performs a crucial role in many applications. 3D printed products vary from fully functional to purely aesthetic applications – commonly for manufacturing. Here we discuss how our engineers use this technology to demonstrate a seal concept. What is 3D printing? The typically common name for additive manufacturing is 3D printing. The process involves the construction of a three-dimensional shape designed and generated from a computer aided design program (or CAD). The most typical process used for 3D printing is FFF (Fused Filament Fabrication) or FDM (Fused Deposition Modelling).The FDM process uses a continuous filament of a thermoplastic material. It’s then deposited onto the 3D print bed, creating layer by layer, gradually building up the 3D model structure. We commonly use this process to create our design and development range of 3D printed models and seal prototypes. What material is suitable for 3D printing? Material compatibility with the process is imperative and a range of thermoplastic grades are used. Typical suitable material grades include; Polylactic acid (PLA), Acrylonitrile Butadiene Styrene (ABS), Thermoplastic Polyurethane (TPU), Nylon and Polypropylene (PP).The most common grade we use for 3D printing is PLA – for its great strength and stability. We’ve also adapted our design process to use more TPU based material grades, as it loosely demonstrates the same properties as elastomer grades and is better for using in prototype programmes where mechanical fit in groove is tested. Why use 3D printing for seals? 3D printing is used for a variety of designs and seal types. From O-rings, gaskets and lip seals – to grommets, multi shot mouldings and large seal assemblies.Using 3D printing during the initial design stages of a project comes with many benefits. The rapid turnaround means a simple seal design will be produced in around 15 minutes. Additionally, even more complicated parts can be manufactured in the same day. We can even print the application housings – a perfect demonstration to an engineer what they can expect from a seal part. They will see the shape and fit for hardware without the lead time and cost of cutting a prototype tool for moulded parts.This solution is particularly suitable for quick turnaround gasket designs. For example for automotive applications or similar critical markets. Our engineers can design the concept and then 3D print a rapid prototype of a gasket to suit a 3D printed gauge groove. Demonstrating to our customers that the seal has been fit checked for installation, builds further confidence in the design recommendation. Our engineers combine the 3D print with FEA simulation reports to offer a fully engineered sealing solution.Learn more about our design and simulation service HERE

3D printing for seals

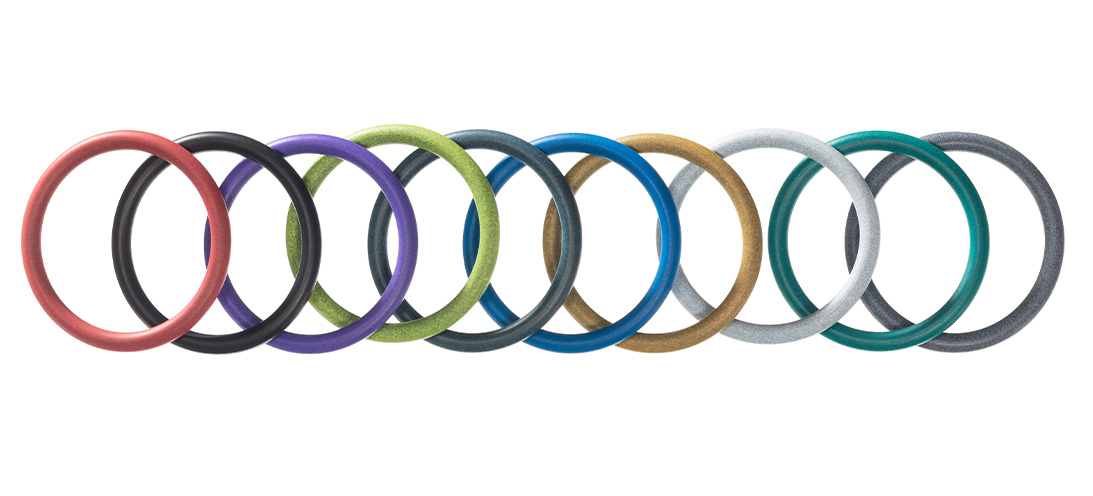

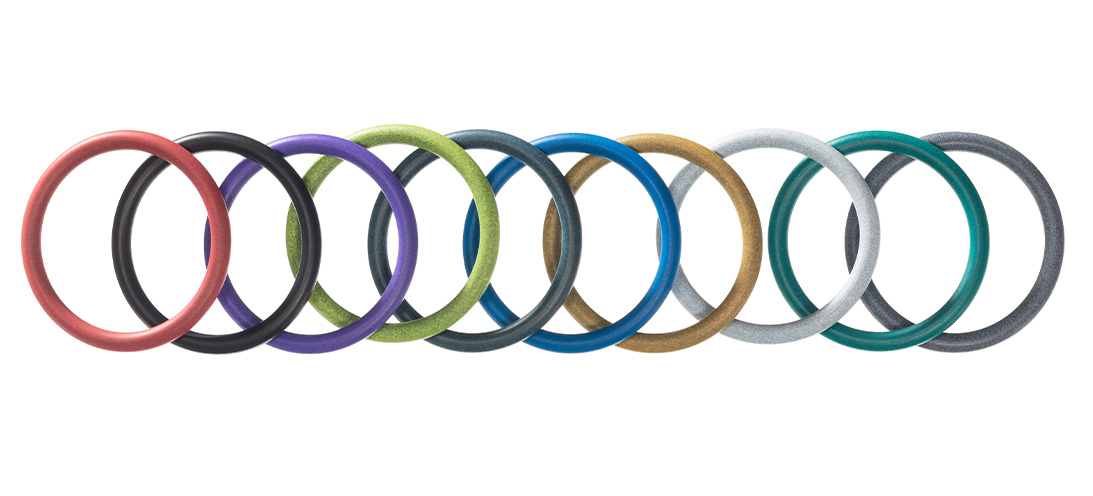

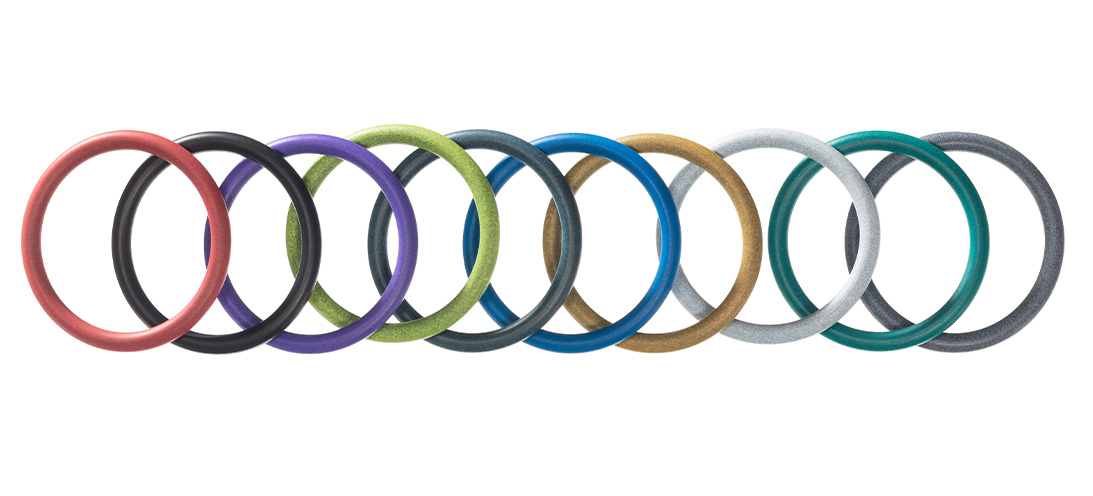

O-rings with special coatingsO-rings with special coatings All seals require some form of installation into application hardware and often this is a simple push in place function. However, without consideration of certain conditions sealing problems could be created further into the life cycle of the seal.Once installation is achieved, a seal often sits in the housing hardware for many months. This potentially allows it to stick to the housing material and cause further issues. This is where O-rings with special coatings can make a difference. Why use special coatings for seals? The main function of coatings is to improve installation into the hardware and to lower friction within an application. Here we discover many other benefits.Coatings often mean that lower assembly forces are required. By not using grease lubricants, seal parts don’t stick together in packaging for transit.Special coatings can be manufactured in different colours. This means seals and O-rings for specific applications are easily identified without the need to reformulate the elastomer compound with colour additives. These reasons make them easier to handle for users during installation. What types of coatings are there? A variety of coatings and lubricants are available for the surface area of seals. These are mainly divided into two common categories: wet coating/lubrication or dry micro film coating.Historically, coating technology was limited to just using wet type coatings. For example, these may include silicone oils and greases and mineral oil-based greases. The coating process would involve simply dipping the seals in the oil or grease during manufacture, or during installation on site. This is often a messy process, and although a relatively low-cost method, wet coating is less common. This is because more applications demand higher levels of cleanliness and control of products, and low contamination has become a key factor.Alongside the typical wet coatings traditionally used, there is an extensive range of what is often referred to as dry coatings. Common offerings are silicone dry coating, PTFE coating, PFPE coating, special polymer coating and MoS2 dry powder coating. These are applied during the manufacturing process and bagged in a clean and efficient process, delivered and ready to be installed into application straight from the bag. Focus on dry coatings Dry coatings are fast becoming the coating of choice for many customers, with PTFE dry coating being one of the most popular. Commonly applied to O-rings, the process involves the PTFE polymer being spray applied to the O-ring elastomer surface area. This creates a microscopic thin film layer. At molecular level, the PTFE creates a covalent like bond to the surface ensure a high quality finish.The low friction properties of PTFE gives the advantage of low assembly forces. For example, an O-ring assembled to a piston can be installed easily into the bore hardware housing mating part. Consequently, this greatly reduces the chance of installation damage (like pinching of the O-ring elastomer material).PTFE coatings are also used as a short term dynamic improvement to a sealing solution, because many seals suffer from the phenomenon called stick slip. This can occur where a seal has remained in the application hardware bore for a medium to long period of time. It then starts to adhere between the surface of the elastomer and the mating metal material, causing sticking.When a PTFE coating is applied between the elastomer and the metal hardware, it creates a low friction barrier. This provides a significant advantage over uncoated parts. This is because the PTFE coating generates a low friction layer, greatly reduces breakout friction and resolves the stick slip issue therefore greatly improving the performance of the application. Coating colours for O-rings Because the PTFE is a thin polymer layer, coatings can be manufactured in a range of colours by adding pigment to the recipe. Typical colours include, green, blue, red, yellow and orange. Adding these colours means the customer benefits from easy identification and production line inspection. Furthermore, seals are more easily identified - even once installed.Find out more about our range of O-rings with special coatings and the different materials O-rings are available in HERE

O-rings with special coatings