Precision Sealing for Naval Radar Slip RingPrecision Sealing for Naval Radar Slip Ring The application Our customer is a globally recognised leader in the design and manufacture of advanced slip ring systems and contactless rotary joints. Their technology ensures the reliable transmission of power, data, and media across a wide range of rotating interfaces. Read more about how our engineers developed a custom spring-energised seal for this application. The application for this project is as demanding as they come. A naval radar system operating in some of the harshest conditions on the planet.Mounted on a naval vessel, the slip ring assembly must operate continuously. Therefore it needs to function flawlessly, protecting electrical components whilst exposed to the elements (seawater, rain and wide temperature fluctuations). The challenges As well as these demanding conditions, the application itself also had several challenges. Furthermore, the design is a compact seal envelope, meaning design and installation need careful consideration.A durable seal is needed - the expectation is that it can withstand over 6 million cycles across a 10-year service life. The seal required minimal breakout friction to avoid wear and conserve energy consumption.This application required a rotary seal with low temperature capability and excellent resistance to oil-based fuels. The new design will replace the existing seal in the available housing between the rotating metal faces. We concluded a standard spring energised rotary seal would not work in the application, therefore we created a bespoke design. Our sealing solution Our engineers developed a custom spring-energised seal, tailored precisely to the application’s needs. We adapted the Parker Praedifa NLO profile and optimised it with a low-load spring for reduced friction, and a high-performance material formulation offering exceptional wear resistance.Additionally, we included a design feature - heel slots allowing for dowel pin integration within the hardware to provide enhanced application stability. Results The final design delivered excellent sealing performance, passed all endurance tests, and met the full 10-year lifecycle requirement. Consequently, it maintained low friction throughout, ensuring energy efficiency and minimal wear. This is exactly what’s needed for a radar system where reliability is non-negotiable.Learn more about our rotary seals HERE.

Precision Sealing for Naval Radar Slip Ring

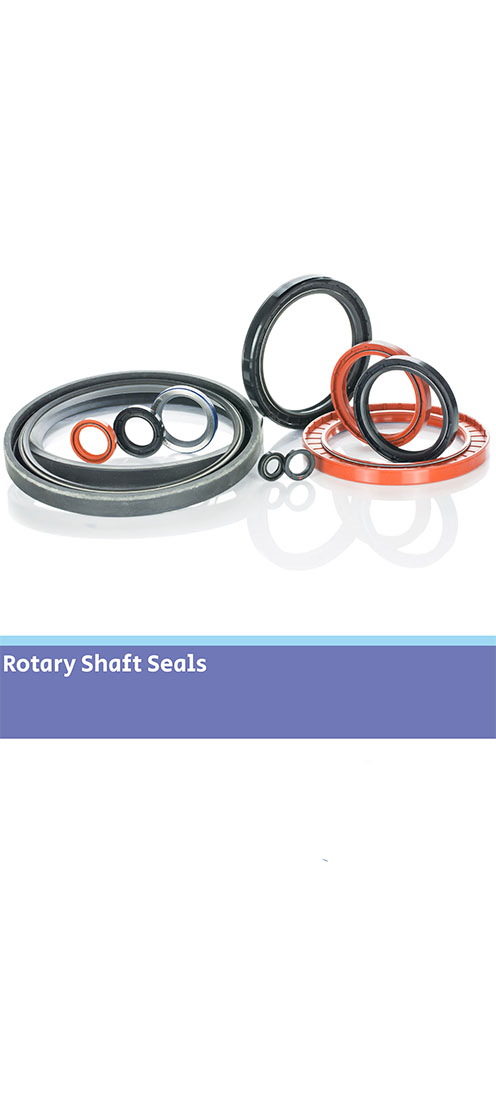

Rotary seals for heavy duty transportationSupply Plus Ltd designs, manufactures, supplies and distributes safety and fuel delivery equipment, with brands including AS Fire & Safety, Bayley and Collins Youldon. They approached us to design a rotary seal to replace their existing solution which was causing leakage during downtime. The application Supply Plus initially approached us with a requirement for their 2” Swing joint power spindle.In this application, the outlet pipe from the fuel tank on delivery vehicles feeds into the centre of a rotating hose reel (located between the tank and cab of the vehicle). An electric motor powers the reel and pumps the fuel through at relatively low pressure.The customer’s main issue with the existing design was leakage. This is from the hose fitting in low temperatures especially at -25°C during winter, and when vehicles were parked over-night. The challenges The application required a rotary seal with low temperature capability and excellent resistance to oil-based fuels. A design was required to replace the existing seal in the available housing between the rotating metal faces. We established that a standard spring energised rotary seal would not work in the application; a bespoke design was required.The leakage at night when vehicles were not in use suggested the issue was worsened when the seal was both cold and not energised. Therefore, we designed a rotary seal that would remain energised at low temperatures and low pressure. Our sealing solution Our engineers designed a simple but effective seal. It incorporated a large heel in the base of the housing that energised a lip sealing on a rotating metal face. The volume of rubber in the heel of the seal, combined with the 170° angled base created sufficient force to maintain a seal at low pressure.We specified a low temperature Viton to ensure the seal retained elastomeric properties. It also applied the sealing force at low energising pressures and very low temperatures. This combination provides excellent resistance to fuel oils, diesel and aviation fuel. Prototypes were tested at both an in-house test unit and in the field for a period of four winter months. Results showed no issues during dispense of fuel and a complete cessation of leakage. The seal was approved and production orders placed, and now the design has been incorporated across additional sizes of hose reels.

Rotary seals for heavy duty transportation

High speed Rotary seals for electric vehiclesHigh speed Rotary seals for electric vehicles The electric vehicle industry is growing; global manufacturing and registrations of electric vehicles is increasing exponentially each year. Our engineers have extensive experience in designing seals for automotive applications, but we still find new challenges involved in sealing components within hybrid, hydrogen fuel and full battery powered electric vehicles. The application Our customer has over 30 years’ experience of providing pioneering technologies globally to the mobility industry. This established company is a supplier of powertrain solutions for electric and hybrid vehicles, additionally traditional internal combustion power engines.Their team of powertrain development experts approached our engineers for a rotary shaft sealing solution for the gearbox within an electric vehicle. The position of the seal was required between the wet transmission and dry e-motor, and pressed into a bulkhead housing.The sealing lip runs on the surface of the transmission rotor shaft and pressed radially by a tension spring onto the shaft. Additionally, it required a dust lip to provide protection against environmental dirt and debris on the dry motor side.The shaft and housing dimensions were all fixed by the customer. However, they provided a full dimensional, surface finish, pressure, temperature and media specification. This enabled our engineers to review and propose a bespoke seal design Our sealing solution The application media was a synthetic oil. This is relatively standard for an automotive application. However, because of the maximum working temperature, FKM (Viton) was the elastomer material to meet the required range.As with many applications within electric vehicle gearboxes, the shaft speed was particularly high at 8500 RPM. Typically, with these high speeds, seal design needs to ensure minimal friction to ensure the service life required.Our application engineers designed a bespoke, double lipped spring energised seal.On the dry e-motor side, the rubber lip was designed to act as a dirt and dust excluder, with slight clearance from the shaft to avoid friction. This prevents damage to the seal and unnecessary wear to the rotary system as a whole.In the wet transmission side, it was imperative that the oil was kept away from the e-motor with the same minimal friction requirements. As a result, our engineers have designed the seal with an inlaid PTFE lip with 15% graphite fill. It was energised with spring to ensure force which achieves ultimate shaft sealing performance.Read more about our rotary seals HERE

High speed Rotary seals for electric vehicles

PTFE Rotary Seal for Oil & Gas drilling toolPTFE Rotary seal for oil & gas drilling tool Our customer designs and manufactures a leading range of unique downhole technology and drilling solutions that contribute to a net zero energy industry. Read on to find out about our PTFE rotary seal solution for their application. The application Our customer tasked us with developing a sealing solution for the rod of a downhole drilling tool. This is a hydraulic dynamic (rotary) application.The normal operating pressure was 500 PSI at 60 RPM; however, maximum pressure could reach 6,500 PSI in static operation. Reverse pressure was unlikely in this application, however, the engineers wanted to ensure some level of resistance.Two single acting seals could be considered, but specifically groove space was limited. Keeping the grooves closed was preferable for bearing strength.The maximum operating temperature could reach 200°C, additionally, the application media was drilling mud and completion fluids. The wiper arrangement was already installed. Our sealing solution Because of the pressure, temperature and chemical media parameters of this application, an elastomer seal selection was not suitable. Our engineers selected our standard FTOR profile PTFE seal. This is a double acting slipper seal ideally suited to hydraulic applications and capable of sealing under alternating pressure directions. It's ideal for sealing high pressure loads with slow to moderate rotational speeds. The PTFE seal has side wall notches equally spaced, therefore the part can be fitted symmetrically either way.The initial sealing force is provided by the elastomer O-ring. This is seated within a machined saddle and activated by system pressure to perform under high pressure demands.The sealing set was also designed with a scarf cut PEEK back-up ring to ensure stability and seal performance at maximum working pressure of 6,500 PSI. Customer satisfaction Our customer tested the sealing arrangement at higher pressure (up to 10,000 PSI). They were pleased to find it sealed successfully over and above the application requirements. They have adopted this seal design for other sizes of parts in similar equipment.

PTFE Rotary Seal for Oil & Gas drilling tool