Using Finite Element Analysis (FEA) in seal designUsing Finite Element Analysis (FEA) in seal design Finite Element Analysis (FEA) is a computerised modelling method for predicting how an object reacts to forces, whether directly applied or generated by pressure, temperature effects or vibration. FEA provides data to help predict how a product will function under those applied conditions. Additionally, it identifies areas where the design can be optimised and improved, without having to test multiple prototypes.Our specialist software uses mathematical models to understand and quantify the effects of real-world conditions on a part or assembly. It can be used to identify potential causes where sub-optimal sealing performance has been witnessed and can also be used to guide the design of surrounding parts. Importantly for products such as diaphragms and boots where contact with adjacent parts may need to be avoided. The software also allows force data to be extracted . For example, compressive forces for static seals and friction forces for dynamic seals can be accurately predicted to help our customers in the final design of their products. Why do we use Finite Element Analysis (FEA)? Our engineers encounter many sealing applications that are critical and have many complicating influences. Envelope size, housing limitations, shaft speeds, pressure/temperature ratings and chemical media are all application parameters that our engineers must consider when designing a seal.In isolation, the impact of these application parameters is reasonably straightforward to predict when designing a sealing solution. However, when you compound a number of these factors (whilst often pushing some of them to their upper limit when sealing) it is crucial to predict what will happen in real application conditions. Using FEA as an iterative tool, our engineers can confidently design and then manufacture robust, reliable and cost-effective engineered sealing solutions for our customers.Starting with a 2D or 3D model of the initial design concept, produced within our advanced CAD system, we then apply the boundary conditions and constraints supplied by the customer, including pressure, force, temperatures, and any applied displacements. A suitable finite element mesh is overlaid onto the seal design, ensuring that areas of most interest have the necessary mesh size to ensure accurate results are returned for these regions whilst utilising larger mesh sizes in areas with less relevance or lower levels of displacement to minimise the computing time required to solve the model.Material properties are then assigned to the seal and hardware components. Most sealing materials are non-linear, whereby the amount they deflect under an increase in force varies depending on how large that force is, unlike the straight-line relationship for most metals and rigid plastics, at least over the displacement range relevant to sealing applications. This complicates the material model, and extends the processing time, but we use in-house tensile test facilities to accurately produce the stress-strain material models for our compounds to ensure the analysis is as representative of real-world performance as possible. What happens with the FEA data? The analysis itself can take minutes or even hours of computing time, depending on the complexity of the part and the range of operating conditions being modelled; behind the scenes in the software, many hundreds of thousands of differential equations are being solved.The results are then analysed by our experienced seal designers to identify areas where the design can be optimised to match the specific requirements of the application; such requirements may be for sealing at very low temperatures, a need to minimise friction levels with a dynamic seal, withstand very large pressures without extruding, or whatever sealing system properties are most important to the customer and the application.Results for the finalised proposal can be presented to the customer as force/temperature/stress/time plots, numerical data or animations showing how a seal behaves throughout the analysis, as appropriate to their needs, and can be used as validation data in their system design process. Project 1 case study Faced with very tight packaging constraints, a customer requested a diaphragm component from us for a valve application. Using FEA, we were able to optimise the design not only of the elastomer diaphragm itself, but also propose modifications to the customers hardware components that interfaced with it in order to increase the available space for the diaphragm, keeping material stress levels low to remove any possibility of fatigue failure of the diaphragm over the life of the valve. Project 2 case study A customer approached us to design a PTFE rotary lip seal that had to meet tight maximum torque requirements as their system was driven by a size-limited low power motor with modest levels of torque available.At the same time, high seal tightness was required as leakage of the media would have caused significant problems.By using an iterative FEA process, we produced a seal design that optimised the sealing lip geometries to provide the lowest levels of rotational friction drag whilst ensuring sufficient contact force to maintain a tight seal, and went on to provide seals that successfully passed customer validation testing.With the increased confidence in a proposed sealing solution that FEA provides, our customers can plan lower levels of physical testing and remove contingency for re-design steps, reducing their project lead times and costs, facilitating a faster and more cost-effective time to market for their new products.

Using Finite Element Analysis (FEA) in seal design

Diaphragms for precise control in critical applicationsDiaphragms for precise control in critical applications In applications that require precise and rapid pressure responses, our diaphragms offer an engineered sealing solution for high performance valves and actuators. Why use diaphragms? Diaphragms provide excellent sealing results in multiple applications. These include valves, actuators, pumps, pressure & flow control, pressure switches/sensors, dispensing, metering, ventilation, and media separation applications. Valves and actuators controlling the flow of liquids or gases frequently utilise diaphragms. This is for fast responses to small pressure changes with excellent hysteresis performance.The sensitivity to signal pressure changes gives reliable valve positioning (with very low hysteresis). Additionally, successful sealing in large diameter, high pressure and long stroke applications can all be achieved with the right design. Large diameter & long stroke engineered diaphragms We have a wide selection of materials (including elastomers, fabric reinforced and thermoplastics). Our range of diaphragms are an excellent seal of choice for a variety of hydraulic and pneumatic applications.With varied manufacturing options, we produce diaphragms up to 46” diameter, and our specialist profiles include convoluted, dished and “top hat” designs in both single acting and double acting formats. Are diaphragms suitable for your application? Our team of application engineers have years of seal design experience. They use the latest developments in technology to assess each individual application, providing a complete seal design service.Our mission is achieving optimal sealing performance in an application. Additionally, we can assist with hardware design to provide the most cost-effective sealing package for our customers. Our modelling and specialist FEA technologies predict the performance of fibre & fabric reinforced materials. This allows us to optimise the tooling in key areas to produce complex geometries.Manufactured in a range of materials with industry specific approvals, our diaphragms can be used in applications across multiple industries. These include oil & gas, process control, potable water management, LPG & natural gas, life sciences and food & beverage.Find out more about our range of diaphragms HERE

Diaphragms for precise control in critical applications

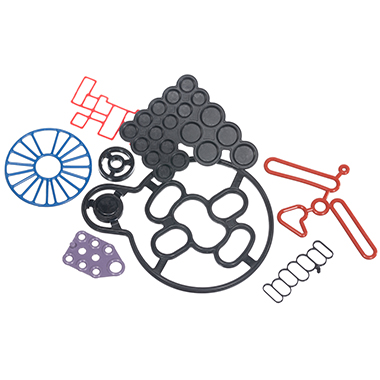

Seals for valve applicationsSeals for valve applications Valves are imperative for isolation and control functions, and can be found in a broad range of industries such as Oil & Gas, Water & Wastewater, Food & Beverage and Hydraulics & Pneumatics. We supply seal products into valve applications in a variety of styles including ball, gate, flap, plug, butterfly, spool, check and solenoid valves. Characteristics of valve sealing There are many challenges involved in valve application sealing. Conditions and application parameters can vary with temperature extremes from cryogenic up to 325°C, and pressures up to 1000+ bar. Materials need to be carefully considered to suit all fluid compatibility required. Often the seal design requires low breakout friction and offers no stick-slip following prolonged static periods when the valve is not used. Alongside this, customers require long service life and minimal maintenance.Different valve styles include ball, gate, flap, butterfly, spool, check and solenoid valves. Additionally, different types of actuation include manual, pneumatic, hydraulic and electro-mechanical. Different areas of the valve demonstrate different sealing requirements - we explore more below. Valve sealing areas - actuation and body bonnet joint ActuationThere are a range of sealing solutions to suit the variety of actuation types employed with valves. This includes diaphragms for pneumatic actuation, rotary and linear hydraulic and pneumatic seals, and gaskets and O-rings.Seal materials are available to suit all ranges of temperatures and media associated with the actuator and any external contaminants it encounters.Body bonnet jointThis is a static sealing location that can often be sealed with an O-ring (a wide range of materials are available to satisfy fluid compatibility). However, dependent on the fluid, pressures and temperatures, metal seals may be more suited to the application. Additionally, housing deflection under pulsating system pressures may worsen compression set sealing issues. Therefore, a custom gasket design could be potentially more suitable than an O-ring. For subsea valves, a sealing solution capable of handling alternating pressure regimes and multiple media types may be required. Valve sealing areas - stem and seat body StemA critical and dynamic sealing location with often demanding requirements. Depending on the application of the valve, the seals used here may see frequent dynamic operation. They will require a long wear life, whilst in other cases, the valve may be static for long periods. It will then require operation with minimal break-out friction forces; in all cases, reliable sealing is paramount.We manufacture a range of linear and rotary seals for this location, using either elastomer or PTFE options. These include chevron sets, spring energised seals, PTFE slipper seals, wear rings and excluders. Full analysis of the valve duty cycle, internal and external medias and pressures must be considered before the optimum sealing solution can be specified.Seat body Valve seats are often mounted in a housing or carrier which has a sealed interface within the valve body. In these cases it can be a critical location to seal correctly. Dependent on the design, the seal location may be subject to upstream or downstream pressures at various points in the valve operation and in some cases fluid flow through the valve can pull or wash-out seals from their grooves if they are not designed to prevent this. As pressure conditions change with valve operation, the seals here may be required to withstand small (but sometimes frequent) movements of the carrier without sticking or wearing. We have a range of seal types and materials including spring energised PTFE and metal seals that can be used in this location (depending on the exact conditions during valve operation and use). Valve seat A wide variety of elastomers and engineered polymer materials can be moulded or machined to suit valve seat components.Bonded rubber to metal or rubber to plastic seals can provide bespoke solutions that offer benefits in terms of space envelope, component count or ease of assembly. Design & Development for valve sealing applications Our engineering team understand the application demands associated with valve sealing. We will support our customers with the design of seals for every position within the valves.Our service is a complete design process- from initial seal geometry and profile choice, to material selection and prototyping, through to final production. We utilise years of seal design experience and materials expertise. This is alongside technology such as 2D/3D CAD and FEA analysis programs to simulate performance before finalising each individual seal design.We are familiar with the requirements of individual markets and their valve applications, and offer seals manufactured in materials with approval requirements such as NORSOK M-710, ISO23936-2, NACE, WRAS and FDA.For more on our design and engineering service, see our dedicated page HERE

Seals for valve applications