Diaphragms for precise control in critical applicationsDiaphragms for precise control in critical applications In applications that require precise and rapid pressure responses, our diaphragms offer an engineered sealing solution for high performance valves and actuators. Why use diaphragms? Diaphragms provide excellent sealing results in multiple applications. These include valves, actuators, pumps, pressure & flow control, pressure switches/sensors, dispensing, metering, ventilation, and media separation applications. Valves and actuators controlling the flow of liquids or gases frequently utilise diaphragms. This is for fast responses to small pressure changes with excellent hysteresis performance.The sensitivity to signal pressure changes gives reliable valve positioning (with very low hysteresis). Additionally, successful sealing in large diameter, high pressure and long stroke applications can all be achieved with the right design. Large diameter & long stroke engineered diaphragms We have a wide selection of materials (including elastomers, fabric reinforced and thermoplastics). Our range of diaphragms are an excellent seal of choice for a variety of hydraulic and pneumatic applications.With varied manufacturing options, we produce diaphragms up to 46” diameter, and our specialist profiles include convoluted, dished and “top hat” designs in both single acting and double acting formats. Are diaphragms suitable for your application? Our team of application engineers have years of seal design experience. They use the latest developments in technology to assess each individual application, providing a complete seal design service.Our mission is achieving optimal sealing performance in an application. Additionally, we can assist with hardware design to provide the most cost-effective sealing package for our customers. Our modelling and specialist FEA technologies predict the performance of fibre & fabric reinforced materials. This allows us to optimise the tooling in key areas to produce complex geometries.Manufactured in a range of materials with industry specific approvals, our diaphragms can be used in applications across multiple industries. These include oil & gas, process control, potable water management, LPG & natural gas, life sciences and food & beverage.Find out more about our range of diaphragms HERE

Diaphragms for precise control in critical applications

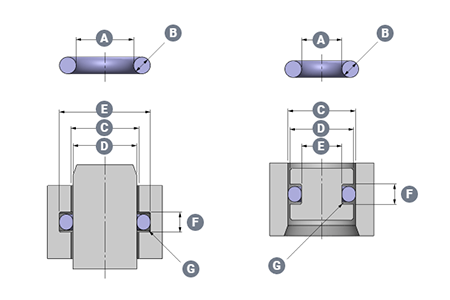

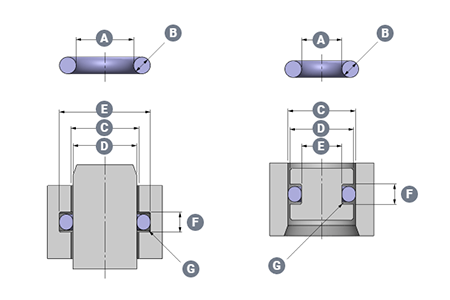

PTFE Rotary Seal for Oil & Gas drilling toolPTFE Rotary seal for oil & gas drilling tool Our customer designs and manufactures a leading range of unique downhole technology and drilling solutions that contribute to a net zero energy industry. Read on to find out about our PTFE rotary seal solution for their application. The application Our customer tasked us with developing a sealing solution for the rod of a downhole drilling tool. This is a hydraulic dynamic (rotary) application.The normal operating pressure was 500 PSI at 60 RPM; however, maximum pressure could reach 6,500 PSI in static operation. Reverse pressure was unlikely in this application, however, the engineers wanted to ensure some level of resistance.Two single acting seals could be considered, but specifically groove space was limited. Keeping the grooves closed was preferable for bearing strength.The maximum operating temperature could reach 200°C, additionally, the application media was drilling mud and completion fluids. The wiper arrangement was already installed. Our sealing solution Because of the pressure, temperature and chemical media parameters of this application, an elastomer seal selection was not suitable. Our engineers selected our standard FTOR profile PTFE seal. This is a double acting slipper seal ideally suited to hydraulic applications and capable of sealing under alternating pressure directions. It's ideal for sealing high pressure loads with slow to moderate rotational speeds. The PTFE seal has side wall notches equally spaced, therefore the part can be fitted symmetrically either way.The initial sealing force is provided by the elastomer O-ring. This is seated within a machined saddle and activated by system pressure to perform under high pressure demands.The sealing set was also designed with a scarf cut PEEK back-up ring to ensure stability and seal performance at maximum working pressure of 6,500 PSI. Customer satisfaction Our customer tested the sealing arrangement at higher pressure (up to 10,000 PSI). They were pleased to find it sealed successfully over and above the application requirements. They have adopted this seal design for other sizes of parts in similar equipment.

PTFE Rotary Seal for Oil & Gas drilling tool

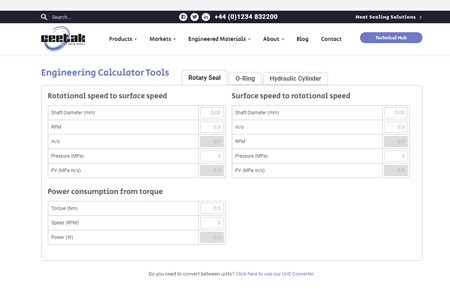

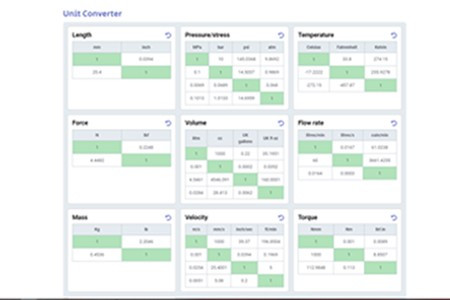

Why use PTFE seals?Why use PTFE seals? Polytetrafluoroethylene (PTFE) is a thermoplastic polymer. PTFE seals can be used in a variety of sealing applications. It’s suitable when application conditions exceed parameters of elastomeric seal use but not to the extent of a metal seal. What is PTFE? It has a high melting point (342 °C) and morphological characteristics. These allow seal components made from virgin PTFE to be used continuously at service temperatures of up to 260 °C. With the addition of fillers – up to 300°C. It has the unique ability to resist material degradation, heat-aging and alteration in its physical properties during temperature cycling. Alongside this rare combination of material characteristics, PTFE also has unlimited shelf life. Why use PTFE seals? Notably PTFE demonstrates extraordinary chemical resistance. The intrapolymer chain bond strengths preclude reactions with most chemicals, thereby making it chemically inert at elevated temperatures and pressures with virtually all industrial chemicals and solvents. Only a few media (some molten alkalis) are known to react with PTFE seals making them the perfect sealing solution for highly aggressive chemical applications.PTFE also has the lowest friction coefficient of any known solid. It has self-lubricating capabilities which offers continuous dry running ability in dynamic sealing applications and has superb stick/slip capabilities. Focus on dry coatings The advantages of using PTFE in sealing applications are multiple:Functionality at high and low temperaturesDynamic sealing with high wear capabilitiesHigh pressure sealing (using combinations of PEEK back-up rings)Compatibility with highly aggressive chemical combinations.Our range of PTFE seal products include back-up rings, rod and piston seals, slipper seals and spring energised seals in a wide variety of sizes. Materials depend on application requirements. However, we offer a wide range from Virgin PTFE or including filler combinations of MoS2, glass, carbon, carbon fibre, graphite, and bronze.These characteristics make PTFE seals perfect for the demanding applications involved in Oil & Gas, Aerospace, Automotive and Chemical Process markets (to name but a few). Ceetak’s engineering team are experienced in the design of PTFE sealing solutions to meet the complex specifications these types of application demand.Read our overview and more detail about PTFE seals HERE

Why use PTFE seals?

Perfluoroelastomers in valvesPerfluoroelastomers in valves Is it time to re-visit using perfluoroelastomer seals in your valves? First developed by DuPont™ in the late 1960s, perfluoroelastomers (or FFKMs), are now widely known and understood in a variety of markets. But for those that may be less familiar with these high performance materials, here is a quick recap... What are perfluoroelastomers (FFKMs)? They are essentially highly or fully fluorinated compounds with a fluorine content above 75%. They offer outstanding chemical resistance - generally better than all other elastomer types. FFKMs are often referred to as having the resistance of PTFE but in elastomer form. The term “universal” chemical resistance is commonly used; although it’s not strictly true as we will learn shortly.Unlike PTFE, the molecular make-up of FFKM includes crosslinks (or spring-like elements). This is instead of just a backbone of carbon-carbon atoms surrounded by protective fluorine atoms. These crosslinks give the FFKMs their crucial elastic behaviour (i.e. returning quickly to their original shape after being deformed). However, the crosslinks are also a drawback as they can be a weak point for a chemical attack.Different crosslinking systems can be used when developing FFKMs and the choice will determine the high and low-temperature capabilities. Compounds developed for extreme high temperatures (up to around 325°C) generally have a less broad chemical resistance compared to the lower temperature grades (up to 225°C). Similarly, FFKMs developed to have excellent resistance to specific fluids (such as amines or high-temperature steam) can have limitations of low-temperature capability or compression set. As a result, there is no universal material that covers all application criteria bases. A variety of grades Previously, the number of perfluoroelastomer grades was less prolific than other elastomer types such as FKM, EPDM, and NBR. However, over 50 years of technical developments have created a range of FFKM grades for specific and challenging applications. These applications are particularly in chemical process, oil and gas, semiconductor, and aerospace industries. The portfolio of FFKM-based compounds available to engineers is now substantial. This is due to many options being available, which include FFKMs with a hardness range of 65 to 90 durometer. Additionally, versions that meet international standards or specifications for food, medical, CPI, and oil & gas applications also being available.In addition to technical developments, manufacturers and compounders have been addressing the only real drawback of FFKM materials; the cost. They are difficult and time-consuming base polymers to manufacture. Coupled with a relatively low volume production base and sometimes lengthy processing times for seal manufacture, FFKM seals have always carried a high financial premium over FKM seals. Even several times greater than FKM itself has over NBR.Recently, there’s been more focus on making general-purpose grade FFKMs with broader temperature and chemical resistance capabilities more financially attainable. The initial procurement costs remain high compared to less capable elastomer bases. However, the overall cost of ownership may now be more appealing than it was twenty or even ten years ago. It is possible for FFKM seals to survive for much longer in applications where exposure to a variety of fluids (perhaps wider than originally specified). This considerably reduces unplanned costs associated with maintenance and downtime. Focus on dry coatings The cost of unscheduled maintenance and repair in pump and valve equipment can be high in any industry. It is exceptionally so in petrochemical, oil & gas, and semiconductor. When these costs are fully considered in the overall lifetime of a product, the initial price of seals in a valve is considered relatively minor. However, it can still be a barrier in the material selection process.With both technical and commercial developments in recent times, FFKM materials now compare more favourably against other materials. These include static, or low-duty dynamic applications in valves. In applications where persistent and sporadic issues keep coming back to cause problems, they are now a more financially attainable choice of material to avoid re-work, overhaul, downtime, customer dissatisfaction, and ultimately, more costs.Read more about FFKM as a suitable sealing material HERE

Perfluoroelastomers in valves

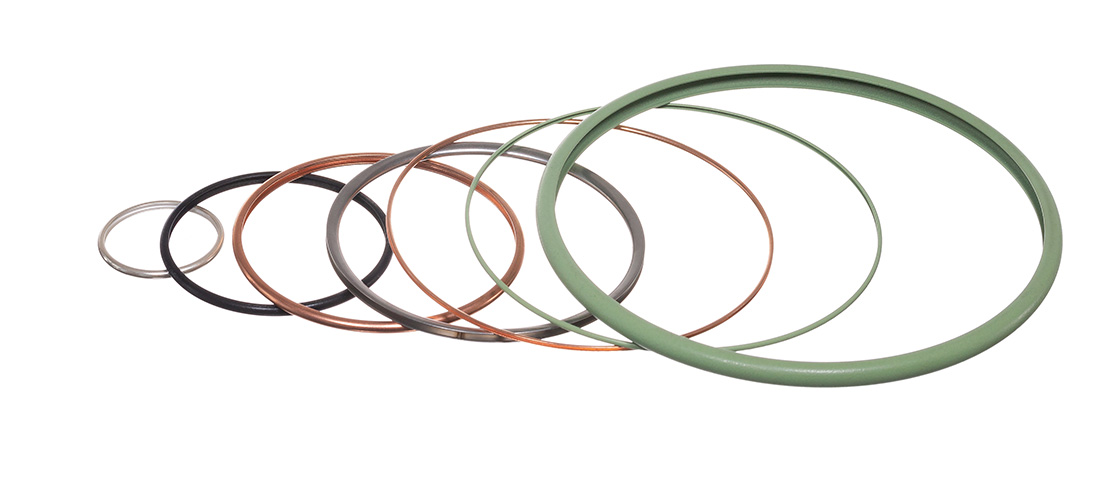

Seals for valve applicationsSeals for valve applications Valves are imperative for isolation and control functions, and can be found in a broad range of industries such as Oil & Gas, Water & Wastewater, Food & Beverage and Hydraulics & Pneumatics. We supply seal products into valve applications in a variety of styles including ball, gate, flap, plug, butterfly, spool, check and solenoid valves. Characteristics of valve sealing There are many challenges involved in valve application sealing. Conditions and application parameters can vary with temperature extremes from cryogenic up to 325°C, and pressures up to 1000+ bar. Materials need to be carefully considered to suit all fluid compatibility required. Often the seal design requires low breakout friction and offers no stick-slip following prolonged static periods when the valve is not used. Alongside this, customers require long service life and minimal maintenance.Different valve styles include ball, gate, flap, butterfly, spool, check and solenoid valves. Additionally, different types of actuation include manual, pneumatic, hydraulic and electro-mechanical. Different areas of the valve demonstrate different sealing requirements - we explore more below. Valve sealing areas - actuation and body bonnet joint ActuationThere are a range of sealing solutions to suit the variety of actuation types employed with valves. This includes diaphragms for pneumatic actuation, rotary and linear hydraulic and pneumatic seals, and gaskets and O-rings.Seal materials are available to suit all ranges of temperatures and media associated with the actuator and any external contaminants it encounters.Body bonnet jointThis is a static sealing location that can often be sealed with an O-ring (a wide range of materials are available to satisfy fluid compatibility). However, dependent on the fluid, pressures and temperatures, metal seals may be more suited to the application. Additionally, housing deflection under pulsating system pressures may worsen compression set sealing issues. Therefore, a custom gasket design could be potentially more suitable than an O-ring. For subsea valves, a sealing solution capable of handling alternating pressure regimes and multiple media types may be required. Valve sealing areas - stem and seat body StemA critical and dynamic sealing location with often demanding requirements. Depending on the application of the valve, the seals used here may see frequent dynamic operation. They will require a long wear life, whilst in other cases, the valve may be static for long periods. It will then require operation with minimal break-out friction forces; in all cases, reliable sealing is paramount.We manufacture a range of linear and rotary seals for this location, using either elastomer or PTFE options. These include chevron sets, spring energised seals, PTFE slipper seals, wear rings and excluders. Full analysis of the valve duty cycle, internal and external medias and pressures must be considered before the optimum sealing solution can be specified.Seat body Valve seats are often mounted in a housing or carrier which has a sealed interface within the valve body. In these cases it can be a critical location to seal correctly. Dependent on the design, the seal location may be subject to upstream or downstream pressures at various points in the valve operation and in some cases fluid flow through the valve can pull or wash-out seals from their grooves if they are not designed to prevent this. As pressure conditions change with valve operation, the seals here may be required to withstand small (but sometimes frequent) movements of the carrier without sticking or wearing. We have a range of seal types and materials including spring energised PTFE and metal seals that can be used in this location (depending on the exact conditions during valve operation and use). Valve seat A wide variety of elastomers and engineered polymer materials can be moulded or machined to suit valve seat components.Bonded rubber to metal or rubber to plastic seals can provide bespoke solutions that offer benefits in terms of space envelope, component count or ease of assembly. Design & Development for valve sealing applications Our engineering team understand the application demands associated with valve sealing. We will support our customers with the design of seals for every position within the valves.Our service is a complete design process- from initial seal geometry and profile choice, to material selection and prototyping, through to final production. We utilise years of seal design experience and materials expertise. This is alongside technology such as 2D/3D CAD and FEA analysis programs to simulate performance before finalising each individual seal design.We are familiar with the requirements of individual markets and their valve applications, and offer seals manufactured in materials with approval requirements such as NORSOK M-710, ISO23936-2, NACE, WRAS and FDA.For more on our design and engineering service, see our dedicated page HERE

Seals for valve applications

Seals for Oil & Gas applicationsSeals for Oil & Gas applications The Oil & Gas industry presents some of the most challenging demands on engineered sealing solutions. Our collaboration with Parker Seal Group allows us to integrate their materials and sealing expertise to meet our customer demands. Characteristics of oil & gas sealing The safe, dependable and efficient operation of a huge range of onshore and offshore equipment is reliant on multiple components. Seals in oil & gas applications are critical to the performance and longevity of equipment, but not without challenges. Conditions typically include low and high temperature extremes and very high-pressure conditions. Additionally, most seals need to withstand aggressive fluids and media such as sour gas, salt water and super-heated steam. There are three main sectors within the Oil & Gas industry, with different processes and equipment requiring sealing solutions.Upstream; commonly known as exploration and production – this refers to the recovery of hydrocarbon reserves in the form of natural gas and crude oil. Midstream; refers to the processes involved in the transportation and storage of natural gas and crude oil, from production site to refinery location. Downstream; includes the processing of natural gas and crude oil at oil plants and petrochemical plants. Well drilling This is the process of extracting oil and gas from beneath the ground, in both onshore and offshore environments. Seals used in these applications have to cope with increasingly harsh environments (with wells becoming deeper and deeper). System pressures up to 30,000 PSI and operating temperatures between -50°C and +220°C are common, and seals have to demonstrate excellent fluid compatibility and resistance against aggressive media – all with longer service life expectations.Applications include; drilling and tool bits, blow-out preventers, drilling mud systems, LWD and MWD test equipment, casing and pipe connections, subsea risers and connector systems, control valves, compressors and pumps.Seals need; high temperature and high pressure capabilities, sour gas and abrasive drilling fluids resistance, extrusion resistance and compatibility with well bore fluids. Well completion This is the process of making a well ready for production after drilling. Similiar to well drilling, seals used in well completion must withstand increasingly harsh condition such as deeper wells and more diverse geographical areas with extreme hot and cold weather conditions. System pressures up to 30,000 PSI and operating temperatures between -45°C and +220°C are common, and seals have to demonstrate excellent fluid compatibility and resistance against aggressive media.Applications include; tubing heads and hangars, packer assemblies, well controls, Christmas trees, cementing equipment, well head completion assemblies, well service.Seals need; high temperature and high pressure capabilities, chemical compatibility (including H2S resistance), RGD & extrusion resistance and steam resistance. Distribution Following on from the production stage, petroleum products are transported to processing facilities and to end users in pipelines. Seals used in midstream distribution sector applications often operate in low temperatures, down to -196°C (required to liquify gas) as well as high temperatures of 480°C (to meet fire test requirements). System pressures can be as high as 10,000 PSI.Applications include; marine and offshore loading swivels and turrets, railcar loading systems, pipeline service equipment (pigs and spheres), pipeline valves & actuators, pumps & compressors, tank & loading systems.Seals need; Extrusion, corrosion and abrasion resistance, extreme temperature and pressure capabilities, chemical compatibility (including H2S), RGD resistance, compliance with NORSOK, ISO and API specifications. API 6A, NORSOK M-710, ISO 23936-2 and TOTAL material qualifications The Oil & Gas industry has specific testing and qualification standards to ensure that materials used in harsh drilling and production environments meet the critical demands of these applications.ISO 23936-2:2011 describes the requirements and procedures for the qualification of elastomeric materials in accordance with media related to oil and gas production. H2S testing in accordance with this specification enables the lifetime prediction of compounds.NORSOK M-710 defines the requirements for critical non-metallic (polymer) sealing, seat and anti-extrusion ring materials for permanent subsea use. This includes well completion, christmas trees, control systems and valves as well as topside valves in critical gas systems.API 6A is the specification for drilling and production, wellhead and christmas tree equipment.Total GS EP PVV142 defines the requirements for non-metallic sealing materials concerning elastomers within pipeline valve applications.In conjunction with Parker Seals we offer a range of products in materials that are qualified to these specifications.We work closely with our oil & gas customers, read more HERE

Seals for Oil & Gas applications

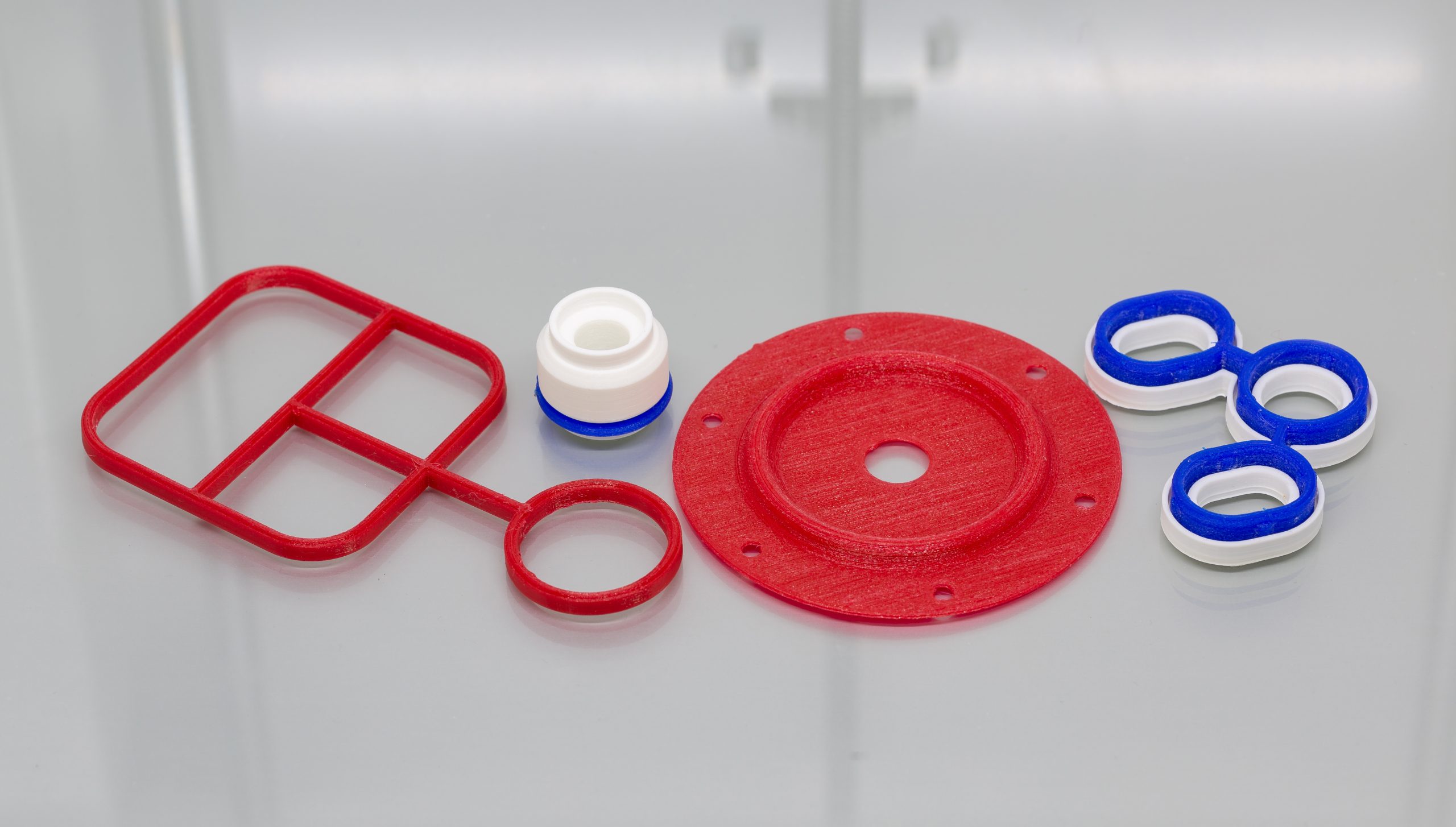

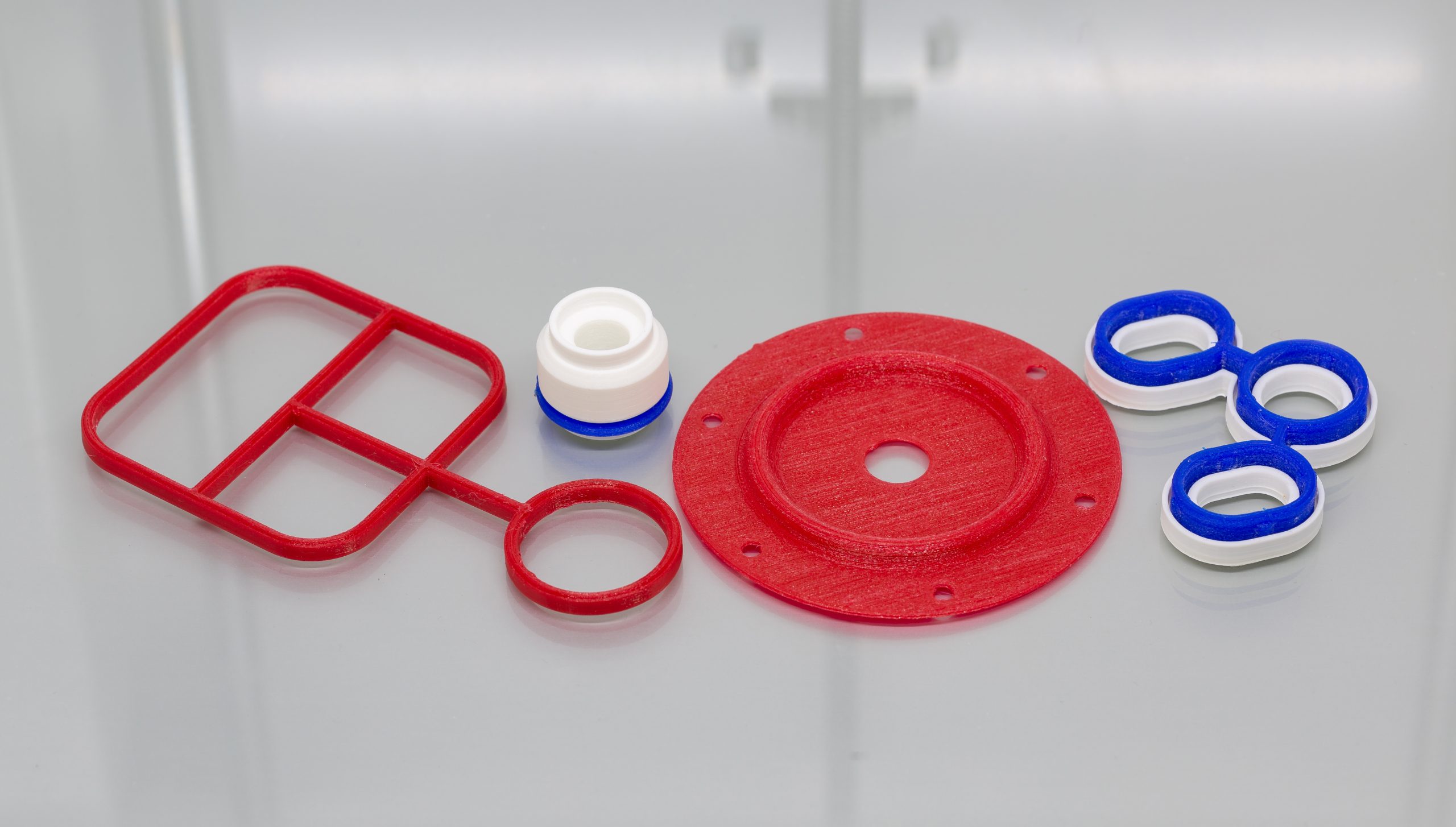

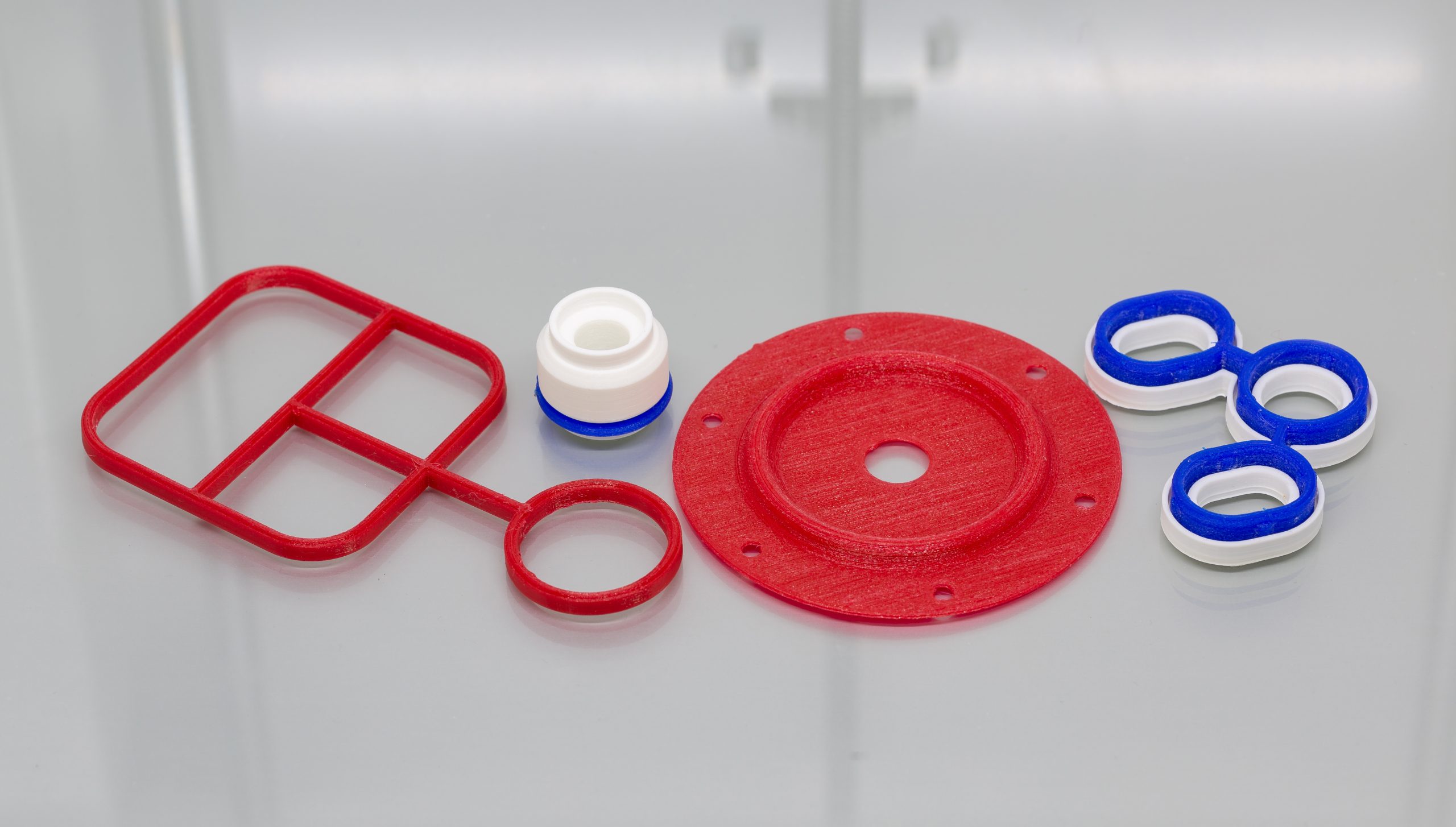

3D printing for seals3D printing for seals 3D printing has developed significantly and now performs a crucial role in many applications. 3D printed products vary from fully functional to purely aesthetic applications – commonly for manufacturing. Here we discuss how our engineers use this technology to demonstrate a seal concept. What is 3D printing? The typically common name for additive manufacturing is 3D printing. The process involves the construction of a three-dimensional shape designed and generated from a computer aided design program (or CAD). The most typical process used for 3D printing is FFF (Fused Filament Fabrication) or FDM (Fused Deposition Modelling).The FDM process uses a continuous filament of a thermoplastic material. It’s then deposited onto the 3D print bed, creating layer by layer, gradually building up the 3D model structure. We commonly use this process to create our design and development range of 3D printed models and seal prototypes. What material is suitable for 3D printing? Material compatibility with the process is imperative and a range of thermoplastic grades are used. Typical suitable material grades include; Polylactic acid (PLA), Acrylonitrile Butadiene Styrene (ABS), Thermoplastic Polyurethane (TPU), Nylon and Polypropylene (PP).The most common grade we use for 3D printing is PLA – for its great strength and stability. We’ve also adapted our design process to use more TPU based material grades, as it loosely demonstrates the same properties as elastomer grades and is better for using in prototype programmes where mechanical fit in groove is tested. Why use 3D printing for seals? 3D printing is used for a variety of designs and seal types. From O-rings, gaskets and lip seals – to grommets, multi shot mouldings and large seal assemblies.Using 3D printing during the initial design stages of a project comes with many benefits. The rapid turnaround means a simple seal design will be produced in around 15 minutes. Additionally, even more complicated parts can be manufactured in the same day. We can even print the application housings – a perfect demonstration to an engineer what they can expect from a seal part. They will see the shape and fit for hardware without the lead time and cost of cutting a prototype tool for moulded parts.This solution is particularly suitable for quick turnaround gasket designs. For example for automotive applications or similar critical markets. Our engineers can design the concept and then 3D print a rapid prototype of a gasket to suit a 3D printed gauge groove. Demonstrating to our customers that the seal has been fit checked for installation, builds further confidence in the design recommendation. Our engineers combine the 3D print with FEA simulation reports to offer a fully engineered sealing solution.Learn more about our design and simulation service HERE

3D printing for seals